GE MIWII - 1000E00HI00 High Precision Counter Module

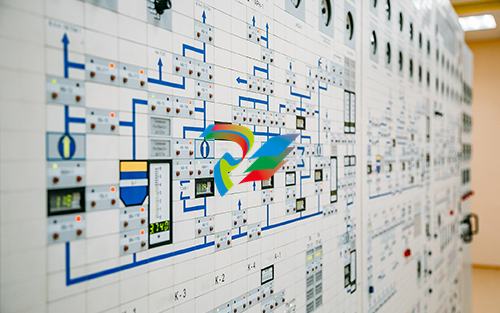

The GE MIWII stands out as a robust and versatile automation component designed to meet the demanding needs of the power industry, petrochemical sector, and general automation applications. Built with advanced engineering, the GE MIWII offers a comprehensive range of technical features that ensure high performance, durability, and seamless integration into complex control systems.

One of the key technical highlights of the GE MIWII is its impressive input/output capacity. With numerous input channels and output points, it facilitates precise data acquisition and control across diverse operational parameters. The device is engineered to handle both digital and analog signals, providing flexibility for various automation processes. Its high-speed processing capabilities enable real-time data handling, minimizing latency and ensuring swift response times critical in safety-critical environments. Durability is a hallmark of the GE MIWII, which is designed to withstand harsh industrial conditions, including extreme temperatures, vibration, and electrical noise. Its rugged construction ensures long-term reliability, reducing downtime and maintenance costs.

Performance metrics of the GE MIWII include robust communication interfaces compatible with standard industrial protocols, enabling seamless integration with existing control systems. Its modular design simplifies installation and maintenance, allowing for easy upgrades and scalability. The device also features built-in redundancy options, enhancing operational safety and system resilience—an essential feature in power generation plants and petrochemical facilities where uptime is paramount.

In real-world scenarios, the GE MIWII excels in a variety of applications. In the power industry, it is used for efficient monitoring and control of power plant operations, ensuring stable and reliable electricity generation. Its precision and durability make it ideal for managing complex automation tasks such as turbine control, switchgear operation, and grid management. In petrochemical facilities, the MIWII’s ability to withstand challenging environments ensures safe and accurate process control, from refining to chemical synthesis. General automation setups benefit from its scalability and flexible input/output configurations, supporting factory automation, assembly lines, and infrastructure management.

Compared to other models within the GE automation product range, the GE MIWII offers distinct advantages. For instance, while models like GE VME-MB-Z004 and GE IS200GDDDG1ACA provide reliable data handling capabilities, the MIWII integrates higher input/output capacities with enhanced environmental resilience. Unlike the GE DS200TCQCG1B or GE IC670MDL644, which may focus on specific control functions, the MIWII’s modular and scalable architecture makes it suitable for a wide array of applications, from small automation tasks to large-scale industrial control systems. Its superior durability and performance metrics position it as a preferred choice for critical infrastructure.

Alongside the GE MIWII, we also offer complementary GE automation products such as the GE IC693CPU372 for processing intelligence, the GE IC660ELB921M for I/O expansion, and the GE IS215VPROH2BC for high-speed control applications. For more specialized needs, models like the GE DS3800HMPK1F1B and GE IC695CHS012 provide additional functionality, ensuring a comprehensive automation solution tailored to diverse industry requirements. Other models such as the GE 8607ERL and GE IC670MDL740 further enhance system robustness and communication capabilities.

In summary, the GE MIWII is a pivotal component in GE’s lineup of automation products, delivering unmatched performance in power, petrochemical, and general industrial settings. Its advanced input/output capacity, rugged durability, and seamless integration make it an ideal choice for demanding applications. When combined with other reliable GE models like GE IS200TRPAS1AFD or GE IC200UEX211-C, it forms a comprehensive automation ecosystem capable of supporting complex, mission-critical operations. For industries seeking reliable, high-performance automation solutions, the application of MIWII in power industry, petrochemical, and general automation environments remains a proven and strategic choice.

| User name | Member Level | Quantity | Specification | Purchase Date |

|---|

Address:Xiamen City, Fujian Province, China

TELL:

E-MAIL:yang@kongjiangauto.com

E-MAIL:gedcs868@gmail.com