Omron SRM 1-C01/CO2-V2 main control Unit (S controller)

The Omron SRM 1-C01/CO2-V2 main control unit (S controller) is an ultra-small independent model device, featuring both CompoBus/S host and SYSMAC controller functions. Its main parameters include: Remote I/O points: Each host supports a maximum of 256 points. The number of slaves: Each host can be connected to a maximum of 32 slaves. Communication cycle time: up to 0.5 milliseconds at the fastest, depending on a baud rate of 750 kbps. Communication distance: Up to 500 meters at a baud rate of 93.75 kbps. Input/output points: Supports 256 points (128 input /128 output) or 128 points (64 input /64 output), which can be selected through DM Settings. The default is 256 points. Input character range: 000 to 007. Output word range: 010 to 017. This device also features additional instructions (such as PID, SCL, NEG, ZCP) to ensure analog compatibility and integrates an RS-232C port (applicable to the SRM1-C02-V2 model). These features make the Omron SRM 1-C01/CO2-V2 a powerful and flexible controller suitable for a wide range of industrial automation applications.

Programming language: Programming is done using ladder diagrams, supporting 14 basic instructions and 81 special instructions. Programming tools: Select the programming console (CQM1-PRO01-E, C200H-PRO27-E), CX programmer (version 2 or higher), or SYSMAC support software (MS-DOS version) for program writing. Program capacity: Ensure that the program does not exceed the capacity limit of 4,096 characters. Data storage and backup: Utilize 2022+512 (read-only) word data storage space. Memory backup: User programs are stored in flash memory (no battery required), while data storage devices, etc. are backed up using lithium batteries. The battery life is at least 10 years (at an ambient temperature of 25 degrees Celsius). Debug and monitor the execution time: 0.97 microseconds for LD instructions and 9.1 microseconds for MOV instructions, and evaluate the program performance based on this. Timer/Counter: 128 timers/counters are used to achieve time control and counting functions. Monitoring and Debugging: Monitor the program's running status through programming tools, and conduct necessary debugging and error detection. Special module configuration analog module: If analog input/output is required, refer to the relevant documentation for correct configuration and programming. High-speed counter module: According to application requirements, configure the high-speed counter module to achieve high-speed counting function. PRM communication module: If communication with other devices is required, configure the PRM communication module and write the corresponding communication program. Through the above steps, the Omron SRM 1-C01/CO2-V2 main control unit can be effectively used for automatic control.

The Omron SRM 1-C01/CO2-V2 main control unit (S controller) has the following advantages: In terms of performance, it is highly efficient in communication: the communication cycle time is as long as 0.5 milliseconds (with a baud rate of 750 kbps), ensuring the rapidity of data transmission and improving the system response speed. Strong compatibility: It has analog compatibility and can meet the connection requirements of different analog devices. In terms of functionality, the control is flexible: It features additional instructions such as PID, SCL, NEG, and ZCP, facilitating users to perform more complex control operations. Convenient programming: Supports ladder diagram programming, with rich instructions, including 14 basic instructions and 81 special instructions, making it easy for users to write programs according to their needs. In terms of scalability, it has strong I/O expansion capabilities: The maximum number of remote I/O points for each host can reach 256, and different I/O point configurations can be selected through DM Settings to meet the needs of systems of different scales. A large number of slaves: Each host can be connected to up to 32 slaves, which is convenient for building a distributed control system. In terms of reliability, the communication distance is long: the maximum communication distance can reach 500 meters (with a baud rate of 93.75kbps), making it suitable for large factories or occasions that require long-distance communication. Reliable data storage: User programs are stored in flash memory (battery-free), and data storage devices are backed up by lithium batteries. The battery life is at least 10 years (at an ambient temperature of 25 degrees Celsius), ensuring the security and long-term preservation of data. In other aspects, it integrates the RS-232C port: The SRM1-C02-V2 model integrates the RS-232C port, facilitating serial communication with other devices. In conclusion, the Omron SRM 1-C01/CO2-V2 main control unit features efficient communication, powerful control capabilities, flexible scalability, high reliability, and convenient programming, and is capable of meeting various industrial automation control requirements.

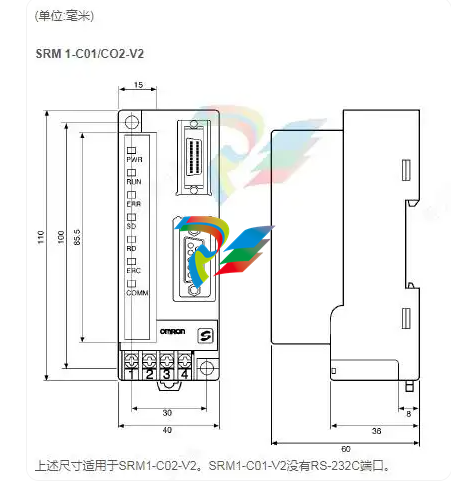

The main parameters of the Omron SRM 1-C01/CO2-V2 main control unit (S controller) are as follows: Basic characteristics Remote I/O points: Each host supports a maximum of 256 points. The number of slaves: Each host can be connected to a maximum of 32 slaves. Communication cycle time: up to 0.5 milliseconds (baud rate of 750 kbps). Communication distance: Up to 500 meters (baud rate of 93.75 kbps). Input/Output Input/output points: 256 points (128 inputs /128 outputs) or 128 points (64 inputs /64 outputs), which can be selected through DM Settings. The default setting is 256 points. Input characters: 000 to 007. Output words: 010 to 017. Programming language for program design: Ladder diagram. Instruction types: 14 basic instructions and 81 special instructions (totaling 125 instructions). Execution time: 0.97 microseconds for LD instructions and 9.1 microseconds for MOV instructions. Program capacity: 4,096 characters. Data storage: 2022+512 (read-only) words. Timers/counters: 128. Workstations: 640. Memory backup user program: Flash memory (battery-free). Data storage, etc. : Lithium battery backup, with a minimum battery life of 10 years (ambient temperature 25 degrees Celsius). Peripheral port RS-232C port: 1 (only applicable to SRM1-C02). Host link, NT link, 1:1 link or no protocol: supported. Programming tool programming console: CQM1-PRO01-E, C200H-PRO27-E. CX programmer: Supported by version 2 or higher. WS02-CXP1-E: Supported. SYSMAC supported software (MS-DOS version) : C500-ZL3AT1-E. These parameters demonstrate the powerful functions and flexibility of the Omron SRM 1-C01/CO2-V2 main control unit in industrial automation control.

.png)

.png)