ABB AC800 series introduction and advantages and disadvantages

ABB AC800

The ABB AC800 series is a series of high performance industrial automation control products, including several models such as the AC800M and AC800PEC, each with unique characteristics and advantages. The following is an introduction to the ABB AC800 series and an analysis of its advantages and disadvantages.

ABB AC800 series introduction

AC800M series

Product features:

High-performance control: Advanced control algorithm and power module can achieve high-performance motor speed regulation and improve the operating efficiency and response speed of the equipment.

Modular design: convenient for users to configure and expand according to actual needs, improving flexibility and scalability.

A variety of communication protocols: support a variety of communication protocols, convenient for users to achieve equipment integration and automatic control, improve the intelligent level of equipment.

Safe and reliable: with a variety of protection functions, such as over current, over voltage, under voltage, overheating, etc., to ensure the safe and reliable operation of the equipment.

Application scenario:

The AC800M series products are suitable for a variety of industrial automation fields, including but not limited to motor control, process control, production line automation, etc.

AC800PEC Series

Product features:

Short cycle time: up to 100 microseconds, suitable for control applications requiring fast response.

Strong processing capacity: dual-core processor unit combined with FPGA technology, to achieve the perfect combination of high-speed control and low-speed process control.

Fast communication and input/output: Fast communication via optical links with data throughput times of less than 100 microseconds.

Advanced control functions: Support MATLAB/Simulink for product and control development to achieve model-based design.

Long life and easy upgrade: Industrial-grade hardware with no moving parts, long service life and easy upgrade.

Application scenario:

AC800PEC is particularly suitable for high-power rectifier applications, such as aluminum electrolysis, electric arc furnace and other industrial process control fields.

Analysis of advantages and disadvantages

Advantages:

High performance: Whether AC800M or AC800PEC, it has excellent control performance and response speed to meet the needs of various industrial automation applications.

Modular design: improve the flexibility and scalability of the system, convenient for users to configure and expand according to actual needs.

Safe and reliable: With a variety of protection functions to ensure stable and reliable operation of equipment in complex and changeable industrial environments.

Easy to use and maintain: friendly operation interface, simple parameter setting, reducing the difficulty of use and debugging; The compact design also facilitates maintenance.

Disadvantages (Specific models may vary based on general analysis) :

High cost: As a high-performance industrial automation control product, its price may be relatively high, which may be a consideration for some projects with limited budgets.

Technical threshold: Although the operation interface is friendly, the implementation of advanced functions still requires certain technical knowledge and experience, and the requirements for operators are high.

Dependence on external systems: In some application scenarios, the AC800 series may require integration with other systems or devices, which may increase the complexity and dependency of the system.

Please note that the above analysis of advantages and disadvantages is based on the general characteristics of ABB AC800 series products, the advantages and disadvantages of specific products may vary depending on the model, application scenario and other factors. In practical applications, it is recommended to select and evaluate according to specific needs.

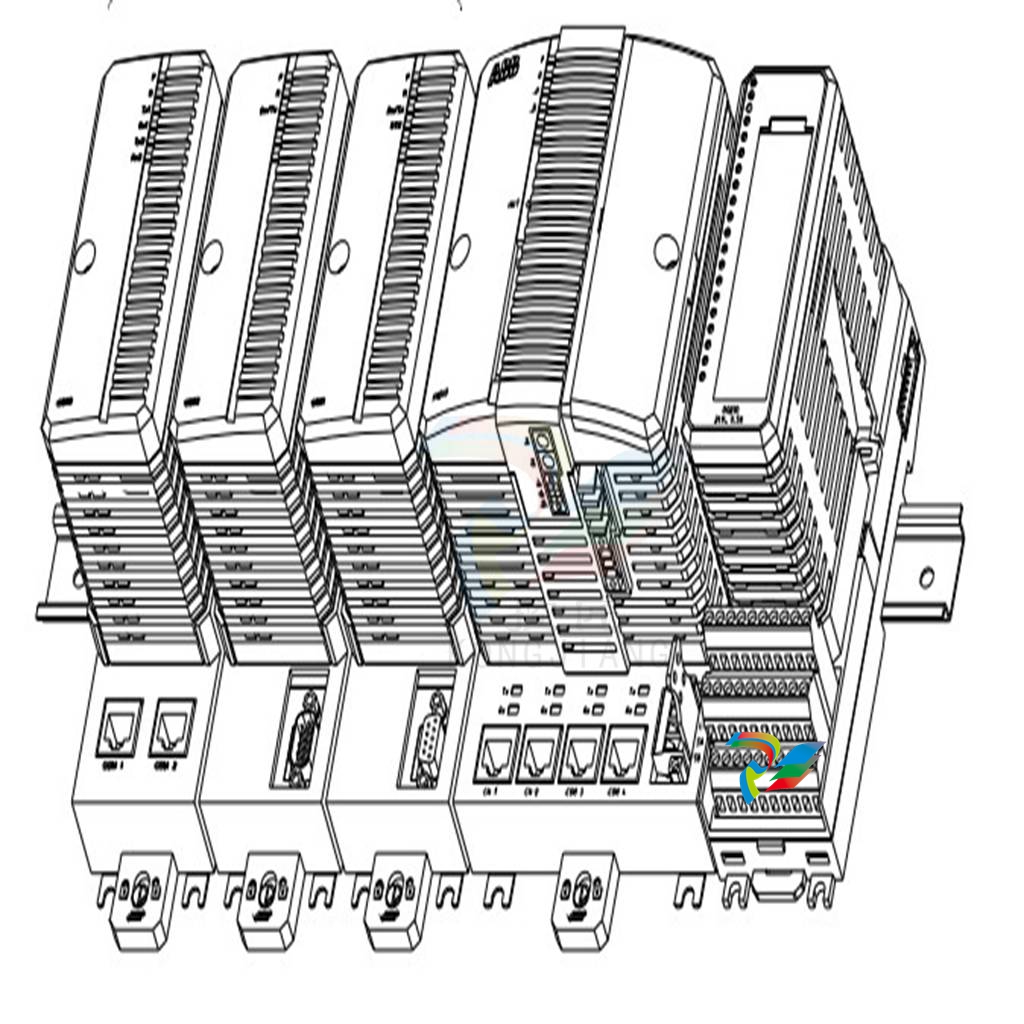

Physical picture:

.png)

.png)

.png)