ABB AC800M series and application range are described in detail

ABB AC800M is an advanced industrial automation control system, widely used in various industrial fields, such as power, pharmaceutical, petrochemical, metal processing, etc. The following is a detailed description of the ABB AC800M:

I. Product overview

The ABB AC800M series is an important part of ABB's industrial automation sector, designed to provide efficient, stable and reliable transmission solutions. The modular design of the product integrates a variety of control functions and communication protocols to meet the needs of different industrial applications.

Second, core features

High performance control:

AC800M series products adopt advanced control algorithm and power module, which can realize high-performance motor speed regulation and improve the operation efficiency and response speed of equipment.

The controller has powerful processing capacity and rich functional modules, which can handle complex control tasks.

Modular design:

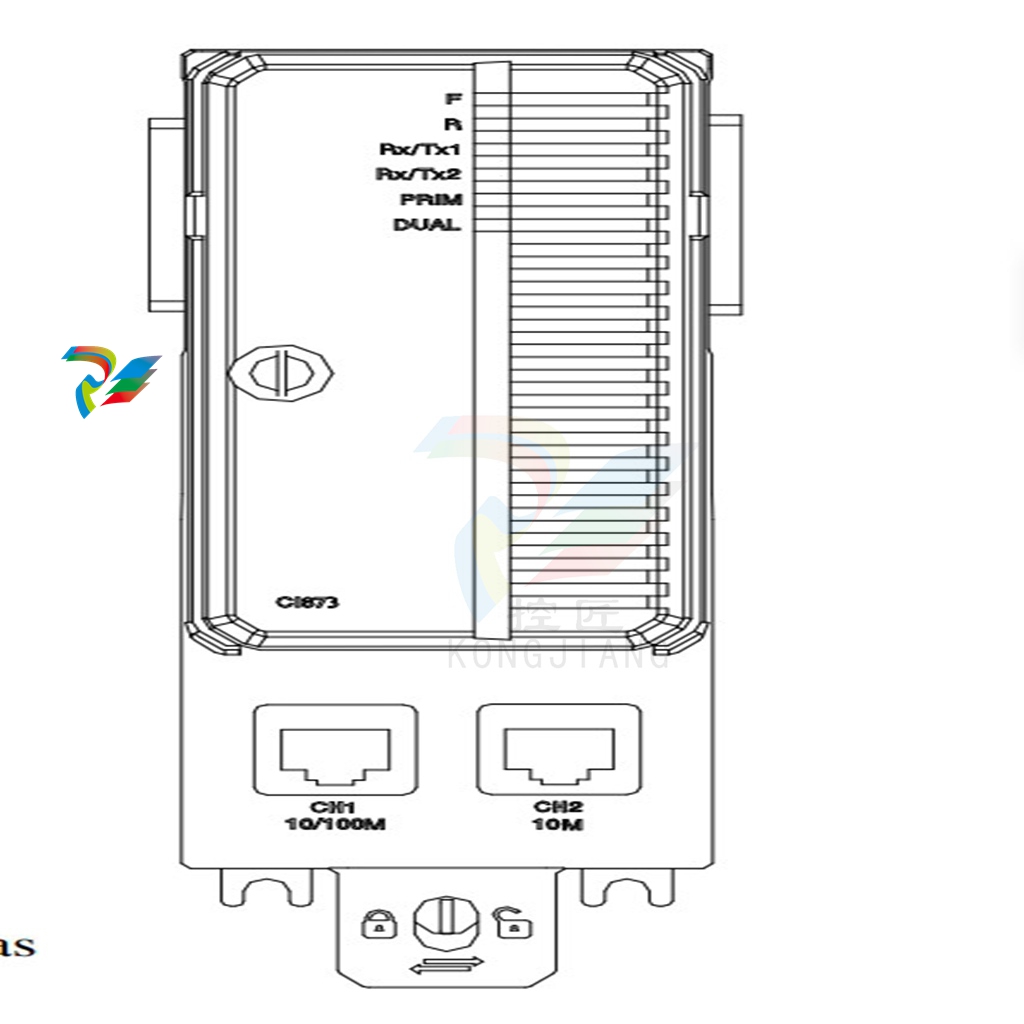

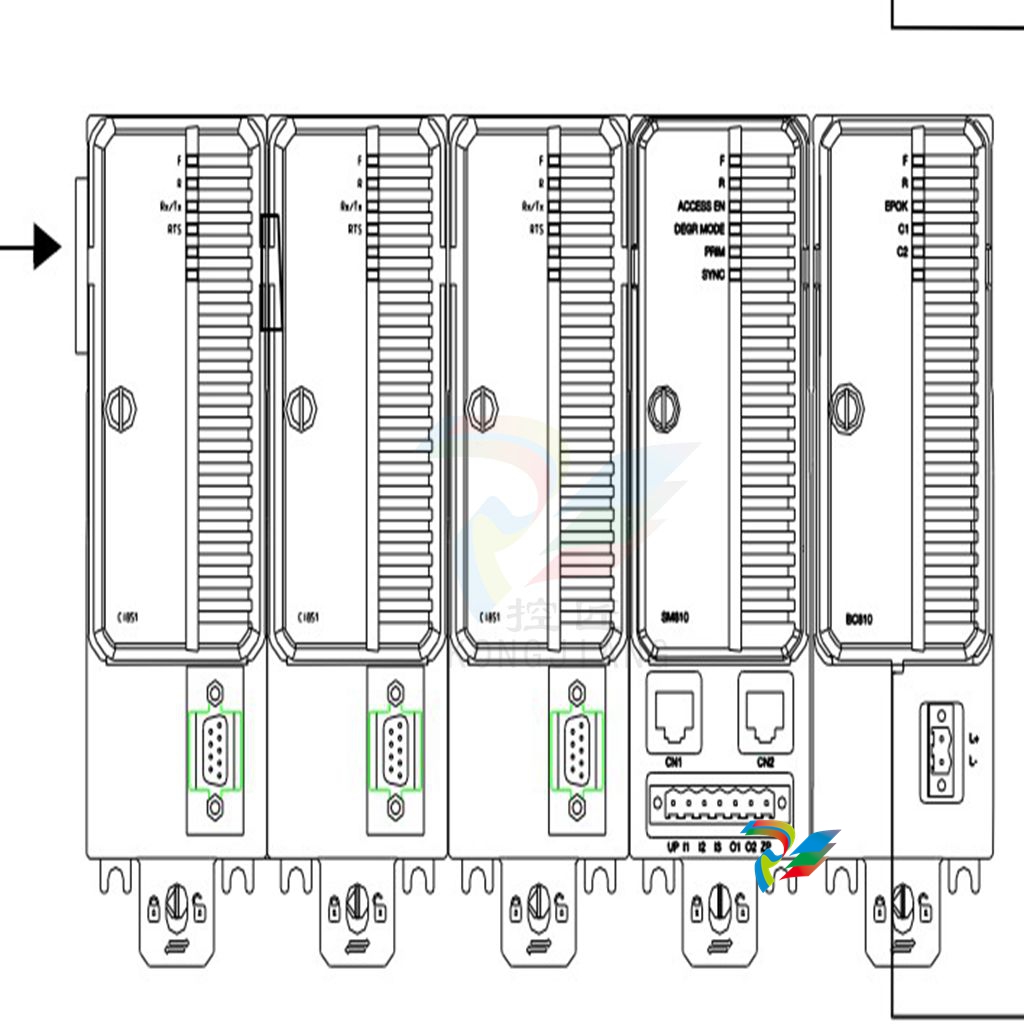

The product adopts modular design, which is convenient for users to configure and expand according to actual needs. Users can select the appropriate controller type (such as PM851, PM856, PM860, PM861, PM864) and expansion modules according to the specific application.

This design improves the flexibility and scalability of the system and reduces the maintenance cost.

Multiple communication protocols:

The AC800M supports a variety of communication protocols such as MasterBus 300, COMLI, Modbus and Siemens 3964R, making it easy to communicate with other controllers, automation systems and field equipment.

The controller integrates 2 Ethernet interfaces, 2 RS232C interfaces, ModulBus electrical and optical fiber expansion interfaces, supports redundancy Settings, and improves the reliability and anti-interference ability of the system.

High reliability and stability:

The AC800M controller uses high-quality components and advanced production processes to ensure its long-term stable operation.

The product has a strong redundancy mechanism, when some components fail, the system will automatically switch to backup components to ensure the stable operation of production.

Easy to use and maintain:

The AC800M controller has a friendly operation interface and simple parameter setting, making it more convenient to use and debug.

The compact design makes maintenance more convenient and reduces maintenance costs.

3. Application cases

ABB AC800M series products have been successfully applied in many industrial fields, providing users with efficient, stable and reliable transmission solutions. For example, in the power industry, AC800M systems can be used to control generator sets; In the pharmaceutical industry, it can be used for automatic control of production lines; In the petrochemical industry, it can be used for the monitoring of oil refining units.

Iv. Summary

As an advanced industrial automation control system product, ABB AC800M has won the trust and praise of the majority of users for its high performance, modular design, multiple communication protocols, high reliability and stability, and easy to use and maintain. In the future, with the continuous development of the industrial automation field, ABB AC800M series products will continue to play an important role in providing strong support for the development of the industrial automation field.

The ABB AC800M has a wide range of applications, covering almost all areas requiring high-performance industrial automation control. The following are the main application areas of ABB AC800M:

Power industry: In power production, ABB AC800M can be used to control generator sets, including thermal power generation, hydroelectric power generation, nuclear power generation, etc. It can precisely control the operation of the generator set to ensure the stability and reliability of the power output.

Petrochemical: In the oil, gas, chemical and other industries, AC800M can be used for the automatic control of oil refining units and chemical production lines. It can handle complex processes to ensure the safety and efficiency of the production process.

Metallurgical industry: In the metallurgical industry such as steel and non-ferrous metals, AC800M can be used for the control of blast furnace, converter, continuous casting machine and other equipment. Through precise control of various process parameters, improve product quality and production efficiency.

Water treatment and environmental protection: In environmental protection facilities such as water treatment plants and sewage treatment plants, AC800M can be used to automatically control water treatment processes, ensure water quality standards and reduce energy consumption.

Food and beverage: In the food and beverage industry, AC800M can be used for automatic control of production lines, including the control of packaging machinery, filling machinery and other equipment. It can improve production efficiency and ensure product health and safety.

Pharmaceutical industry: In the pharmaceutical production process, AC800M can be used to automatically control the production line to ensure the accuracy and stability of the drug production. It can meet the requirements of the pharmaceutical industry for high cleanliness and high accuracy.

.png)

.png)

.png)