ABBAutomatic Transfer Switch

1. Symbols & Terms

1.1 Use of symbols

Risk of Electric shock: warns about a situation where a hazardous voltage may cause physical injury to a person or damage to equipment. General warning: warns about a situation where something other than electrical equipment may cause physical injury to a person or damage to equipment. Caution: provides important information or warns about a situation that may have a detrimental effect on equipment. Information: provides important information about the equipment

Risk of Electric shock: warns about a situation where a hazardous voltage may cause physical injury to a person or damage to equipment. General warning: warns about a situation where something other than electrical equipment may cause physical injury to a person or damage to equipment. Caution: provides important information or warns about a situation that may have a detrimental effect on equipment. Information: provides important information about the equipment

1.2 Explanations of abreviations and terms

OTM_C21D Automatic transfer switch, the type name

LN1-Switch I Power supply line, e.g. the primary line

LN2-Switch II Power supply line, e.g. the secondary line used in emergency cases

EMRG OFF Used to drive the automatic transfer switch transfers to the “O” position when receiving EMRG OFF signal

AUTO Automatic mode

Remote test A sequence to test the functionality of the automatic transfer switch

Ts Transfer delay

TB s Return delay

OV Adjustable overvoltage threshold

UV Adjustable undervoltage threshold

2. Product overview

2.1 Product overview and packing

The OTM_C21D automatic transfer switch can be

used as a source transfer switch in a three-phase

or single-phase networks. Monitored conditions are,

no-voltage, phase-loss, overvoltage and undervoltage

detection, transfer delays, generator start and stop, and

remote test function. Source transfer can be performed

using a manually

operated handle, locally using push buttons or fully automatically. The automatic mode includes several operating methods: Line 1 priority, no line priority and manual back switching mode. OTM_ C21D can achieve communication function by using the optional external Modbus RTU module.

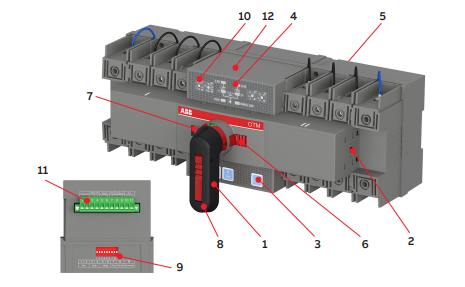

1. Handle for manual operation

2. Place for auxiliary contact blocks

3. Push button

4. Mimic panel

5. Voltage sensing connections

6. Locking clip for padlock

7. Locking latch for releasing the handle and locking electrical control

8. Locking clip for locking manual operation

9. Dip switches

10. Rotary switches

11. Connecting terminal

12. Modbus RTU acces

2.2 OTM_C21D switching sequence

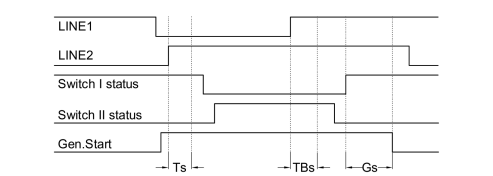

2.2.1 Line 1 Priority (default mode)

The transfer sequence of OTM_C21D can be summarized in following steps:

• An anomaly occurs on the Line 1 (LN1)

• Generator start, immediately start generator in case of black-out, phase-loss, overvoltage or undervoltage (If Generator mode is selected)

• The Line 2 start the normal functioning, transfer delay Ts

• Change-over switch (Switch I) to the position 0

• Change-over switch (Switch II) to the position II

And the return sequence can be summarized in the following steps:

• The Line 1 will start the normal functioning

• Return delay TBs

• Change-over switch (Switch II) to the position 0

• Change-over switch (Switch I) to the position I

• Generator stop delay Gs

• Generator stop

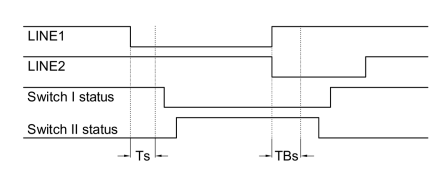

2.2.2 No line priority

The transfer sequence of OTM_C21D can be summarized in following steps:

• An anomaly occurs on the Line 1 (LN1)

• Transfer delay Ts, in case of black-out, phaseloss, overvoltage and undervoltage conditions

• Change-over switch (Switch I) to the position 0

• Change-over switch (Switch II) to the position II

And the return sequence can be summarized in the following steps:

• The Line 1 will start the normal functioning

• Change-over switch stays in position II • An anomaly occurs on the Line 2 (LN2)

• Return delay TBs

• Change-over switch (Switch II) to the position 0

• Change-over switch (Switch I) to the position I

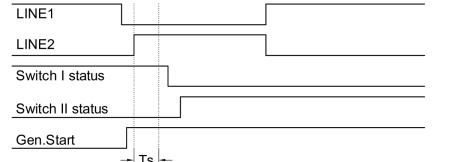

2.2.3 Manual return mode

The transfer sequence of OTM_C21D can be summarized in following steps:

An anomaly occurs on the Line 1 (LN1)

• Generator start, immediately start generator in case of black-out, phase-loss, overvoltage or undervoltage (If Generator mode is selected)

• The Line 2 start the normal functioning, transfer delay Ts

• Change-over switch (Switch I) to the position 0

• Change-over switch (Switch II) to the position II

And the return sequence can be summarized in the following steps:

• The Line 1 will start t

• Change-over switch stays in position II

• An anomaly occurs on the Line 2 (LN2)

• Change-over switch stays in position II

• Change-over switch can be transferred manually back to position I

3. Quick start

3.1 Operating the switch manually (local operation)

To operate the switch manually:

1.Attach the handle to the switch panel. You can attach the handle in any position.

.jpg)

.jpg)

.jpg)

.jpg)

.png)

.jpg)

.jpg)

_lVjBYb.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)