YOKOGAWA Introduction to CENTUM VP

Introduction to CENTUM VP

The Yokogawa CENTUM VP is an advanced integrated production control system, representing the latest evolution in a Distributed Control System (DCS) family that spans over forty years. Designed for a wide range of industries, it aims to enhance productivity and optimize plant operations. CENTUM VP is built on a foundation of being scalable, flexible, and reliable, with a strong focus on safe performance. It provides a unified platform that integrates control, safety, and asset intelligence, preparing facilities for digital transformation and the incorporation of new technologies like the Internet of Things (IoT).

Core Architecture for High Availability

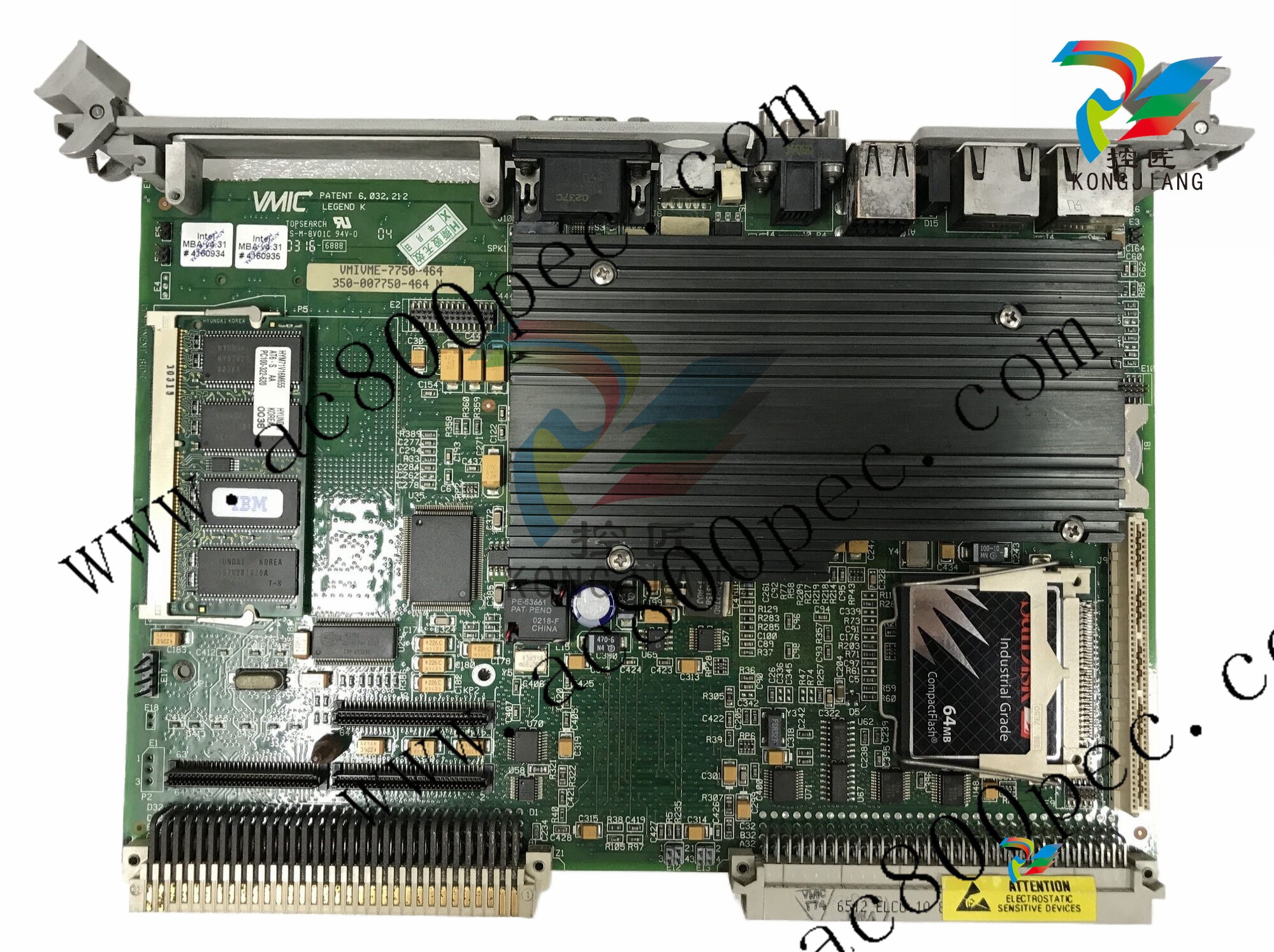

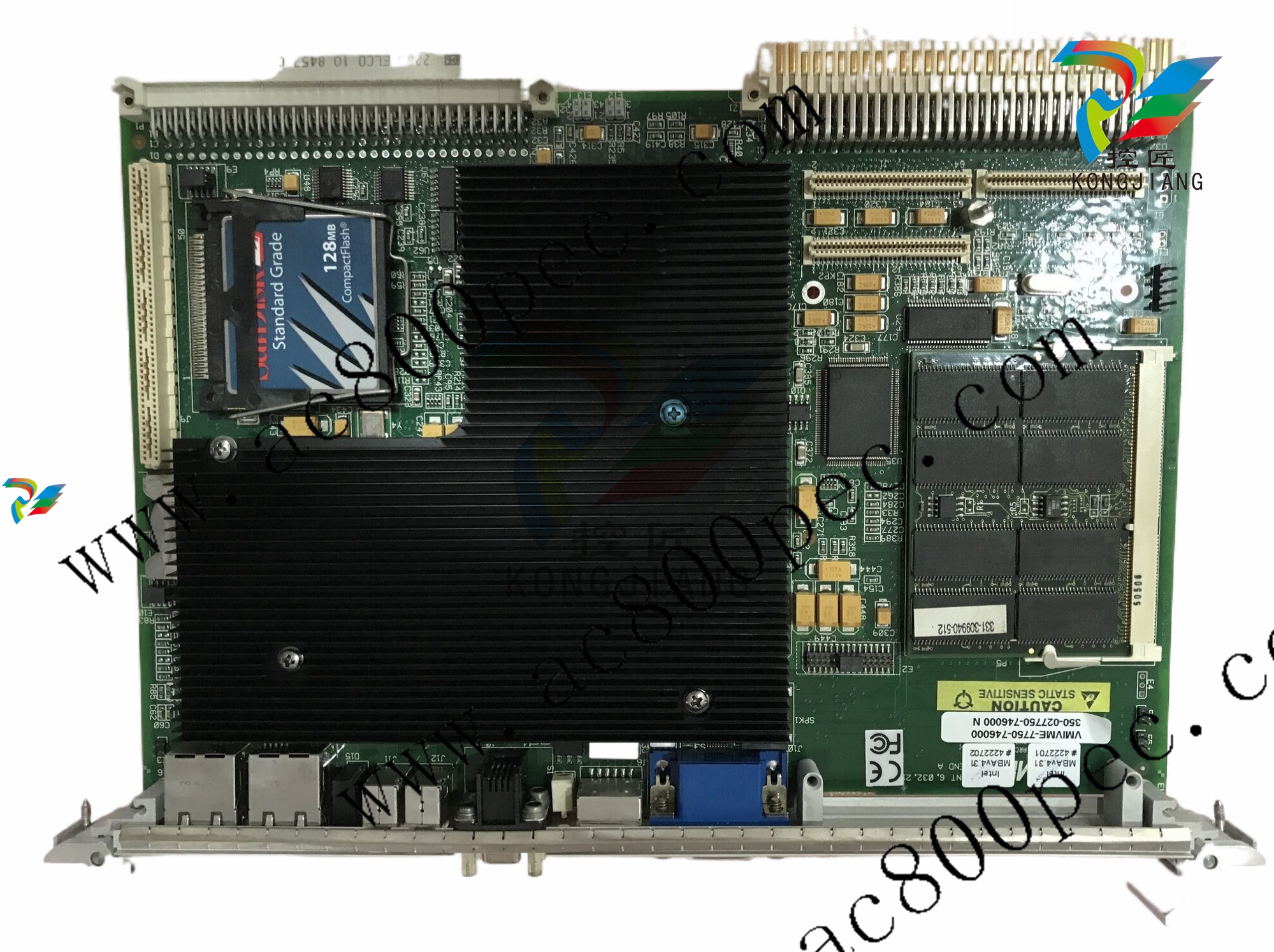

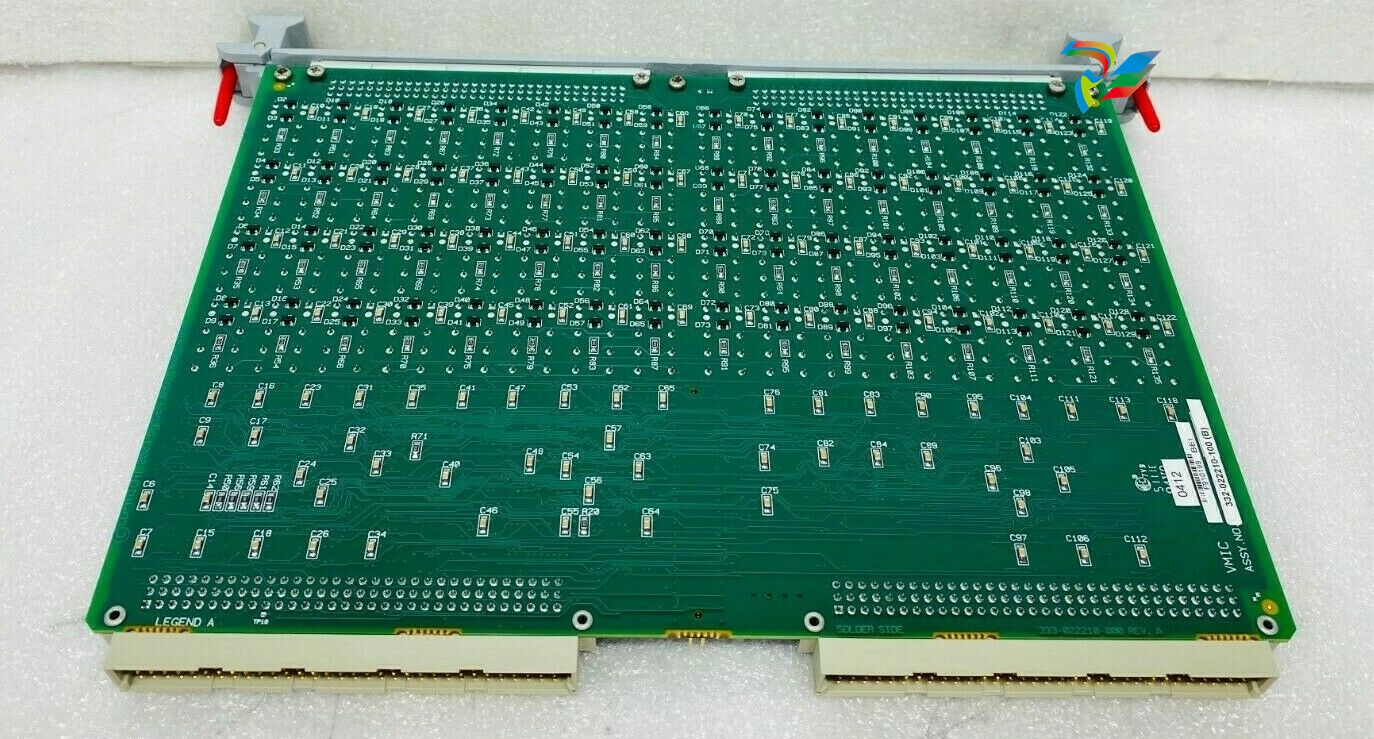

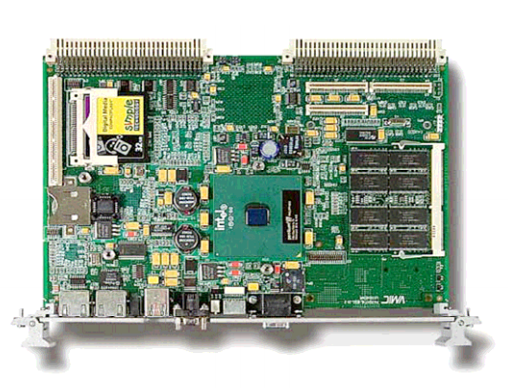

At the heart of CENTUM VP's reliability is its robust control architecture. The Field Control Station (FCS) is engineered for maximum availability, featuring a dual-redundant design for its processor modules, power supplies, I/O modules, and networks. This ensures that control seamlessly switches to a standby module in the event of a failure, allowing for uninterrupted plant operation. The system employs a unique "pair & spare" architecture where redundant Main Processing Units (MPUs) execute computations in parallel, constantly comparing results to detect anomalies and initiate a bumpless switchover, thus ensuring process stability. The secure and deterministic Vnet/IP control network, operating at 1 Gbps, guarantees reliable data communication across the plant.

Advanced Engineering and Project Execution

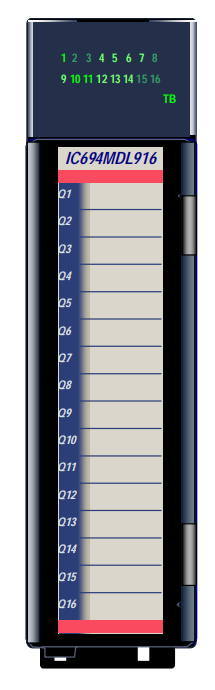

Yokogawa introduces a new engineering paradigm with its Automation Design Suite, designed to improve quality, reduce complexity, and accelerate project delivery. This suite utilizes a modular engineering approach where design patterns for process loops, graphics, and alarms can be standardized and reused, saving significant time and resources. A key innovation is the "Flexible I/O Binding" solution, which uses software marshalling and the versatile N-IO (Network I/O) modules. This allows I/O configurations to be modified remotely even late in the project, decoupling hardware and application engineering and significantly reducing the impact of last-minute changes, thereby minimizing project risks and shortening start-up times.

Integrated Operations and Lifecycle Management

CENTUM VP offers an intuitive, human-centric Human-Machine Interface (HMI) that integrates data from the DCS, the ProSafe-RS Safety Instrumented System, and the Plant Resource Manager (PRM) for asset management. This provides operators with a unified view and an embedded Consolidated Alarm Management System to prevent information overload and enable efficient, safe operations. Yokogawa also emphasizes long-term sustainability through its "Sustainable Plant" concept. This includes comprehensive lifecycle services, ensuring customers can perform online maintenance, apply security patches, and execute seamless system upgrades and migrations from legacy systems (both Yokogawa and third-party) with minimal downtime, thereby protecting their investment and ensuring the lowest total cost of ownership.

Robust Cybersecurity

Recognizing the increasing threat of cyber attacks, CENTUM VP is built with robust security features. The field control unit has achieved ISASecure Embedded Device Security Assurance (EDSA) certification, confirming its resilience against cyber threats. The Vnet/IP network includes built-in protections against spoofing, falsification, and Denial-of-Service (DoS) attacks. Furthermore, Yokogawa provides a comprehensive Endpoint Security Service, which includes verified antivirus software, whitelisting solutions, and other measures to protect the control system from malware and unauthorized access, ensuring the safety and integrity of plant operations.

Address:Xiamen City, Fujian Province, China

TELL:

E-MAIL:yang@kongjiangauto.com

E-MAIL:gedcs868@gmail.com