Summary of Control Functions for CENTUM CS 1000

Summary of Control Functions for CENTUM CS 1000

Introduction to CENTUM CS 1000

The CENTUM CS 1000 is a distributed control system (DCS) specifically developed for medium- and small-scale plant operations. A primary objective behind its design is the reduction of the Total Cost of Ownership (TCO), which encompasses not only hardware maintenance but also the significant costs associated with developing and maintaining control applications. The system integrates the robust and highly-regarded control functions of the broader CENTUM CS family into a compact, maintainable unit. It emphasizes ease of engineering for system creation and modification, as well as flexible communication with a diverse range of field control equipment, such as programmable logic controllers (PLCs).

Core Control Architecture and Reliability

The control functions of the CENTUM CS 1000 are built into each Field Control Station (FCS). Basic control applications are constructed by assembling modular software components known as "function blocks," which represent the minimum units of control algorithms (e.g., PID controllers, selectors). For more complex processes, sets of function blocks can be grouped to simplify the control and monitoring of entire process units. To ensure high reliability, the FCS employs the field-proven synchronous hot stand-by system. This means that in the event of a primary CPU failure, control is seamlessly switched to a stand-by CPU without interrupting control actions, a critical feature for maintaining stability, especially in sequence-control-oriented batch processes.

Enhanced Engineering and Communication Flexibility

To improve engineering efficiency, the CENTUM CS 1000 provides FCS templates. These pre-configured databases are tailored for specific applications like regulatory control or sequence control, appropriately allocating resources within the FCS's memory and CPU load limitations. This simplifies the setup process, which would otherwise require significant expertise. A key innovation is the separation of communication functions from the control application. Data from external subsystems is fetched and stored in a dedicated "communication I/O area." The control application accesses this data via relative addresses or user-defined labels, automatically identifying the data type. This decoupling means the core control logic does not need to be modified even if the communication protocol or connected subsystem changes, greatly enhancing flexibility. For non-standard protocols, communication programs can be custom-coded in C language.

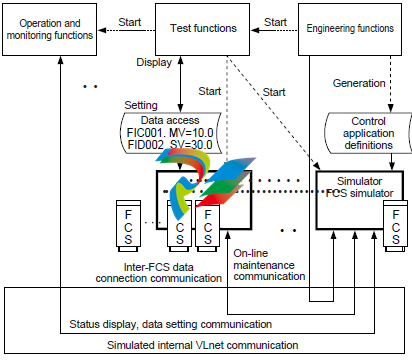

The FCS Simulator for Virtual Testing

A standout feature of the CENTUM CS 1000 is the newly developed FCS simulator function, which runs on a standard PC under the Windows NT operating system. This powerful tool allows engineers to create a virtual FCS on their computer, enabling them to fully simulate and test control application definitions without requiring any actual FCS hardware. The simulator communicates with operation and monitoring functions using a simulated internal network, making the testing environment functionally identical to a real system. Furthermore, a "station intercommunication simulator" can mimic data exchange with other FCSs. This allows for the isolated testing of applications that are part of a larger, interconnected system, enabling multiple engineers to work concurrently and significantly boosting efficiency. This virtual test environment drastically reduces the cost and effort associated with the engineering and inspection phases of a project.

.png)

.png)

.png)