B&R Power Panel 300/400 Series: Comprehensive Technical Manual and Application Guide

B&R Power Panel 300/400 Series: Comprehensive Technical Manual and Application Guide

Introduction

The B&R (Bernecker + Rainer) Power Panel 300/400 series represents a line of high-performance devices in the industrial automation sector, integrating control, operation, and visualization into a single unit. As the successor to the popular Power Panel 100/200 series, this new generation delivers more than double the computing performance, bringing capabilities previously reserved for industrial PCs into the compact panel format. This guide aims to provide a comprehensive overview of the Power Panel 300/400 series' technical specifications, software environments, commissioning, and maintenance points, serving as a detailed reference for engineers and system integrators.

1. Product Line Overview

The Power Panel 300/400 series continues B&R's mature product line strategy to meet the demands of various application scenarios.

Power Panel 300 (BIOS Devices)

These devices are functionally equivalent to standard PC systems, capable of running operating systems like Windows XP Embedded and Windows CE. Their application range is extremely broad, suitable for everything from simple thin clients and web terminals to full-featured SCADA (Supervisory Control and Data Acquisition) systems.

Power Panel 300/400 (Automation Runtime Devices)

These are embedded systems designed for the complete automation of systems. They integrate powerful control functions and drive technology, connecting to process peripherals through modular interfaces, making them the core of efficient and reliable automation solutions.

2. Core Technical Specifications

The Power Panel 300/400 series is designed with the harsh requirements of industrial environments in mind, featuring the following key characteristics:

Processor: Utilizes a Geode LX800 500 MHz, 32-bit x86 processor, providing robust data processing capabilities.

Memory: Depending on the model, it can be configured with up to 512 MB of DDR SDRAM. Models for Automation Runtime are typically equipped with 128 MB SDRAM and up to 512 KB of battery-backed SRAM for remnant variables.

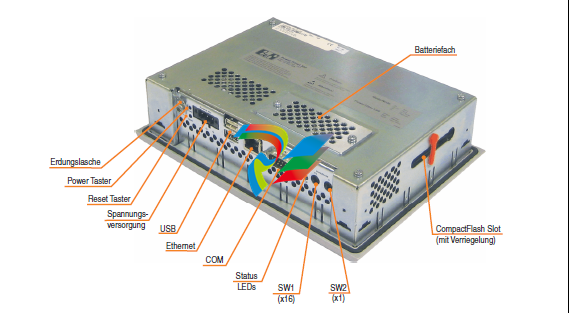

Storage: A side-accessible, securely lockable CompactFlash Type I slot serves as the primary non-volatile storage medium.

Display and Operation:

Offers a variety of display sizes and resolutions, from 5.7-inch QVGA to 15-inch XGA.

Input methods include a high-precision resistive touch screen or a combination of function keys and soft keys with LED indicators.

Supports both landscape and portrait mounting to accommodate different installation spaces and application needs.

Interfaces:

Power Supply: Wide-range 18-30 VDC power input.

Ethernet: An onboard Intel 82551ER controller provides a 10/100 MBit/s RJ45 Ethernet port.

USB: 2 USB 2.0 ports, each capable of supplying up to 500 mA of current.

Serial: 1 non-isolated RS232 COM port that supports modems.

Construction and Environmental Adaptability:

Features a fanless design, ensuring stable operation in harsh environments through passive cooling (heat sink).

A rugged metal housing with an IP65-rated front panel provides effective protection against dust and water splashes.

Modular Expansion: Power Panel 400 models can be equipped with up to two aPCI slots for expanding fieldbus interfaces like CAN, X2X, or other functional modules.

3. Software and Operating Systems

To meet diverse application needs, the Power Panel series supports a variety of software and operating system environments.

BIOS: PP300 BIOS devices use a B&R-optimized Insyde BIOS, allowing users to perform low-level system configuration via an external USB keyboard. Configuration information is stored in battery-backed CMOS RAM.

Automation Runtime: B&R's proprietary real-time, multitasking operating system that provides a unified runtime environment for all B&R automation components, ensuring program consistency and determinism.

Windows CE (5.0 & 6.0): This is a compact operating system optimized for embedded devices, featuring fast boot times and high stability. The Windows CE image provided by B&R is tailored for the hardware and includes key components like Internet Explorer 6.0, .NET Compact Framework, and Remote Desktop Protocol.

Windows XP Embedded (XPe) / Windows Embedded Standard 2009 (WES2009): These are modularized versions of Windows XP Professional, offering powerful features and compatibility for industrial applications, including features like Enhanced Write Filter (EWF) to protect system files from unintentional modifications.

4. Installation and Commissioning

Proper installation and commissioning are crucial for ensuring the long-term stable operation of the device.

Safety Requirements: All installation, commissioning, and maintenance tasks must be performed by qualified personnel.

Installation Regulations:

The device must be secured using the supplied mounting clips.

To ensure adequate air circulation and heat dissipation, sufficient space (at least 80mm is recommended) must be left above, below, to the sides, and behind the unit.

Supports 0° (vertical) and ±45° tilted mounting, but the interface side must face downwards.

Touch Screen Calibration:

All touch screen devices are pre-calibrated at the factory. However, it is recommended to perform a recalibration after initial startup or device replacement to achieve the best user experience based on the specific application and user habits.

In Windows CE and Windows XP Embedded systems, touch screen calibration is typically performed during the first boot or driver installation. In an Automation Runtime environment, calibration must be implemented within the customer's application.

.png)

.png)

.png)