Product Description of F3236 Digital Input Module

The F3236 Digital Input Module is a high-reliability industrial I/O component designed for precise and real-time monitoring of digital signals in critical automation and safety systems. As a key part of industrial control architectures, this module converts external digital signals (such as status signals from sensors, switches, or actuators) into processable data for controllers, enabling accurate status detection and rapid response in complex industrial environments.

Core Functions and Features

High-Speed Signal Acquisition: The F3236 module supports high-frequency digital signal sampling, ensuring real-time capture of on/off status changes from field devices. With minimal input delay, it guarantees timely data transmission to the controller, critical for time-sensitive safety and control logic.

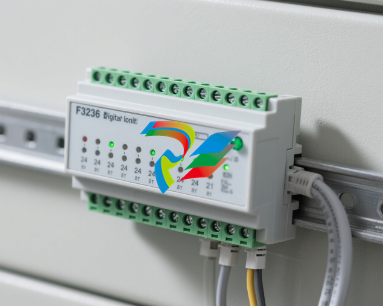

# F3236 Digital Input Module User Manual ## 1. Overview The F3236 Digital Input Module is a high-performance industrial control component designed to collect and transmit digital signals in automated systems. It features stable operation, high anti-interference capability, and flexible configuration, making it suitable for various industrial environments such as manufacturing, power, and transportation. ## 3. Installation Instructions ### 3.1 Mounting - The module should be installed on a standard DIN rail (35mm) in a control cabinet. - Ensure adequate ventilation around the module to prevent overheating; maintain a minimum distance of 50mm from heat sources. - Tighten the mounting clips securely to avoid vibration-induced loosening. ### 3.2 Wiring - **Power Supply**: Connect the DC 24V power supply to the terminals marked "V+" (positive) and "V-" (negative). Reverse polarity protection is included, but incorrect wiring may cause temporary malfunction. - **Digital Inputs**: Connect external devices (e.g., sensors, switches) to the input terminals (CH1-CH16). For dry contact inputs, connect the common terminal (COM) to one side of the contact and the channel terminal to the other. For voltage inputs, ensure the signal matches the input range. - **Communication**: Use shielded twisted-pair cable for RS485 communication. Connect A (positive) and B (negative) terminals to the corresponding bus lines; ground the shield at one end to reduce interference. ## 4. Operation Guide ### 4.1 Power-On Check - After wiring, verify all connections are correct before powering on. - The power indicator (PWR) will illuminate green when the module is powered on normally. - Input status indicators (CH1-CH16) will light up red when a high-level signal (or closed contact) is detected. ### 4.2 Parameter Configuration - Configure communication parameters (baud rate, parity, address) via Modbus RTU commands using a configuration tool or PLC. Default settings: Baud rate = 9600, Parity = None, Address = 1. - Adjust input filter time if needed (default: 1ms) to suppress noise; longer filter times reduce response speed. ### 4.3 Data Reading - Read input status via Modbus function code 0x02 (Read Discrete Inputs). The module returns a 16-bit data frame, where each bit corresponds to an input channel (1 = active, 0 = inactive). ## 6. Maintenance and Safety - Regularly inspect wiring terminals for corrosion or loosening; clean with a dry cloth if necessary. - Avoid exposure to dust, moisture, or corrosive gases; use a protective enclosure in harsh environments. - Disconnect power before performing maintenance or wiring modifications to prevent electric shock. ## 7. Warranty The F3236 Digital Input Module comes with a 2-year warranty from the date of purchase. Warranty does not cover damage caused by improper installation, wiring errors, or unauthorized modification. **Note**: For further technical support, contact our service team at support@example.com. *Document Version: V1.0 | Date: 2025-08-18*

| User name | Member Level | Quantity | Specification | Purchase Date |

|---|