Advant Controller 31 Series 40 and 50

1 Introduction

This chapter gives you an introduction to the AC31 automation, from the overall architecture to

the operational rules of the 40 and 50 series basic units

1.1 General information on the AC31 system

The AC31 system consists of the series 30, 40, 50, and 90. This operating manual describes the series 40 and 50.

The AC31 brings accessibility to beginners and experienced automation users alike, for any application with 14 to

approximately 1000 inputs / outputs and more, using the same set of basic components. From a compact machine

fitted with a few automated functions to large installations spread over hundreds of meter, and even kilometers, th

e AC31 can fit your requirements. It is therefore possible to realize distributed applications throughout a site, a wor

kshop, or a machine where each component (input / output units, basic unit) is close to the sensors / actuators. T

he whole setup is connected by a single twisted pair over which all information from the sensors is sent after proc

essing by the basic unit to the actuators via the remote modules. Additional central units configured as slave can

also be connected to this CS31 system bus. In case of the series 40 and 50 the following communication interface

s are available, to extend the AC31’s possibilities and integration with the company's other automation systems: M

ODBUS, ASCII, ARCNET, RCOM, AF100. The developments in this field are continua

Many users on all the continents have realized numerous applications such as:

Machine control:

- Manufacturing of floor boards

- Assembly of electrical contactors

- Manufacturing of ceramic products

Controlling-commanding installations:

- Wharf cranes

- Water treatment

- Ski lifts

- Wind power machines, etc.

System management:

- Climatic anagement

- Building power management

- Tunnel ventilation

- Alarms in hospital environments

- Greenhouse lighting / humidity, etc.

1.2 General set-up rules

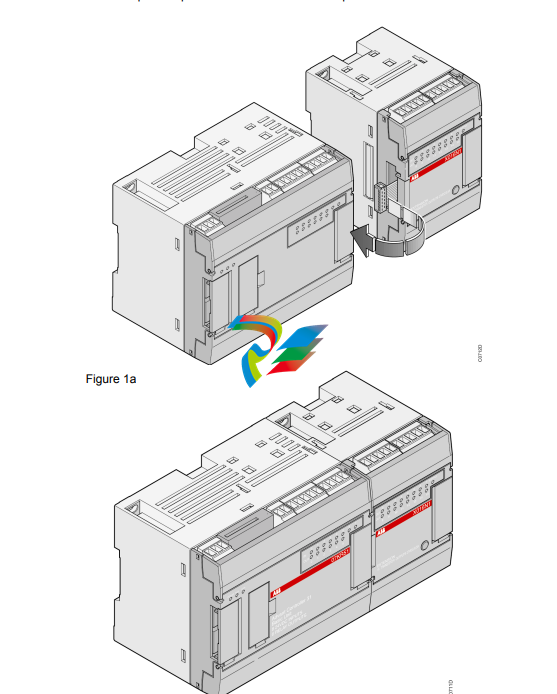

An ABB AC31 system always includes at least one

AC31 basic unit. There are three types of basic un

its: - The 40 series basic unit, with a local interface

for central inputs / outputs extensions - The 50 ser

ies basic unit, with a local interface for central inpu

ts / outputs extensions and a CS31 system bus inter

face for decentralized extensions - The 90 series basi

c unit, with a CS31 system bus interface for decentrali

zed extensions Each basic unit incorporates a specific

number of digital inputs/outputs and in case of the

series 90 occasionally analog inputs/outputs. It is po

ssible, depending on the basic unit, to increase the

number of inputs / outputs, to add input / output e

xtensions connected directly to the basic units or re

mote input / output units via the CS31 twisted pair.

A master basic unit can manage up to 31 connection points, such as: - Series 50

remote units with central extension possibilities: a maximum of 6 extension units

comprising of e. g. a maximum of 8 analog input channels and 8 analog output c

hannels - Series 30 and 90 remote unit (without central extension possibilities) wi

th analog or digital inputs / outputs - An ABB NCSA-01 variable speed drive interfa

ce - A high-speed counter unit - 30, 50 and 90 series basic units as slave with the

ir own user program - Or any other device which supports CS31 communication. C

omment: A connection point fitted solely with digital channels occupies 1 connecti

on point. A connection point fitted with digital and analog channels occupies 2 con

nection points of the available 31. The maximum number of remote analog units d

epends on the MASTER basic unit: - 50 series: - a maximum of 31 remote analog i

nput units or - a maximum of 31 remote analog output units or - a maximum of 15

central extensible remote units (ICMK 14 ..) with analog input/output extensions +

1 remote analog input/output unit (15 x 2 + 1 = 31) or - a mixed digital/analog co

nfiguration within the previous limits - 90 series: - a maximum of 12 remote analog

input units or - a maximum of 12 remote analog output units or - a maximum of 1

.png)

.png)

.png)