GESPEEDTRONIC™ MARK V STEAM TURBINE CONTROL SYSTEM

INTRODUCTION

The SPEEDTRONIC Mark V is the latest version of GE’s long series of highly reliable electrohydraulic control (EHC) systems for steam turbines. Its heritage consists of a long list of

successful control systems, including the first EHC

Mark I steam turbine control built in the 1960s,

and the SPEEDTRONIC Mark I-IV gas turbine

control. The Mark V continues to combine the

best turbine and generator design engineering

with the latest electronic controls engineering to

provide a modern, yet experienced controls package (Figure 1).

The Mark V is the third generation of triple-redundant microprocessor-based turbine controls that originated in 1982, with the Mark IV1 and was followed in

1987, with the DCM2. GE has an installed base of

over 1,000 running triple-redundant, steam and gas

turbine control systems. The Mark V family of turbine controls for the 1990s, offers a common control

architecture for small, medium, and large steam turbines, turbine-generator monitoring systems, generator excitation systems, and gas turbine controls.

Some of the features are:

• Common Architecture, Maintenance, and Spare

Parts between steam turbine, gas turbine,

and other controls

• Very flexible, PC-based operator interface

with Color Monitor and Logging Printer with

alarm log, event log, historical trip log, etc.

• Common operator training and controls for steam

and gas turbines in combined-cycle STAGTM

plants

• Full Turbine-Generator Monitoring for all sizes

of turbines can be included

• High Resolution Time Tags including 1 ms time

tags of contact inputs

• New Communication Links to plant controls

• Distributed Multiprocessor Control in each controller for maximum processing capability

• Enhanced Diagnostics that can isolate a fault to

the card level in any of the triple-redundant

controllers

• On-Line Repair of the triple-redundant controllers

• Standard built-in Synchronizing Check

Protection

• Fully Digital Valve Positioning to provide a

more linear response of the steam turbine

• Direct Interface to Turbine Devices, including

proximity monitoring equipment

• Compact Packaging in half the cabinet size of

the previous control system

CONTROL SYSTEM HISTORY

From their introduction in the late 1800s,

steam turbines were governed by mechanical

hydraulic control (MHC) systems. Speed was controlled by a flyweight governor of James Watt heritage, signals were transmitted by levers and links

or hydraulic pressure signals, and motive power to

control steam valves was provided by low-pressure

hydraulics. Refined to the utmost, this technology

was used through the mid-1960s, to control such

sophisticated units as double-extraction industrial

turbines, large double-reheat fossil units, and the

first nuclear units incorporating pressure controls

for BWRs. The complexity of these later controls

clearly showed that a new technology was needed.

ANALOG CONTROLS

GE introduced the electro-hydraulic control

(EHC) system for steam turbines in the 1960s.

The first medium-size unit went into service in

1961, and the first large reheat unit in 1968. The

proportional controls used analog circuitry with

dual redundancy for speed control and single

channel for other controls. The logic and protective system was implemented with relays.

The original Mark I system consisted of discrete

component analog circuitry. In the 1970s, these

circuits were modernized to take advantage of integrated circuitry (IC) technology as well as solid

state logic circuits for some of the protection and

logic. This resulted in the EHC Mark II, which had

many IC components and a new cabinet arrangement, while the subsequent Mark III, used only on

small- and medium-sized turbines, employed ICs

throughout and also included electronic speed

sensing and microprocessors for automation.

A major improvement for both medium and

large steam turbine controls was a reduction in

component count with a resultant increase in reliability. The EHC Mark II version for large steam turbines, in addition to integrated circuits, also introduced triple-redundant protection systems for the

functions that can cause a turbine trip, resulting in

further improvement in running reliability by virtually eliminating spurious forced outages.

The associated high-pressure hydraulic system,

using 1600 psig (110 bar) fire-resistant fluid, has

undergone gradual improvement through the

years. The basic technology is still in use for the

new electro- hydraulic controls.

The history of analog controls, as well as the

new digital controls, is summarized in Table 1.

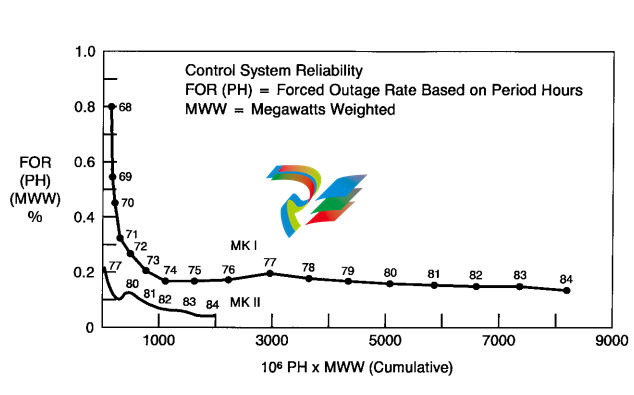

The reliability of EHC systems developed

according to a classic learning curve shown in

Figure 2. The step change in reliability realized

with the EHC Mark II is attributed to two factors:

the superior reliability of integrated electronics

and the introduction of triple-redundant protection logic described above.

DIGITAL CONTROLS

While GE steam turbines were being shipped

with these EHC systems through the mid-1980s, in

the early 1980s, GE’s Gas Turbine Division introduced the very successful triple-redundant digital

control system – the SPEEDTRONIC Mark IV.

The first triple-redundant steam turbine control

system for utility turbines, the DCM system, was

Figure 2. Control system reliability, PH is forced outage rate based on period hours; MWW is megawatt

weighted

shipped in 1987, building on gas turbine experience, including the use of many of its electronics

modules, and developing it further with Software

Implemented Fault Tolerance (SIFT). A companion single-channel system, the Mark III Plus,

aimed at the smaller industrial units, was first

shipped in 1988.

Some of the benefits from the new digital systems are flexibility and greater precision of of

the benefits from the new digital systems are flexibility and greater precision of controls because

functions are determined by software rather than

hardware, CRT operator interface, data link

interface to plant level control systems, and online repair capability for triple-redundant systems, providing further improvement in reliability.

The new SPEEDTRONIC Mark V Steam

Turbine Control System is developed from this

long evolution of electronic steam turbine controls. It is available in both triple-redundant Mark

V TMR and single-channel Mark V Simplex control systems, the only difference being the two

additional controllers in the TMR design.

STEAM TURBINE

UNIT CONTROLS

The main functions of a modern steam turbine

control system are:

• Speed and acceleration control during start-up

• Initialization of generator excitation

• Synchronization and application of load in

response to local or area generation dispatch

commands

• Pressure control of various forms: inlet,

extraction, back pressure, etc.

• Unloading and securing of the turbine

• Sequencing of the above functions under

constraint of thermal stress

• Overspeed protection during load rejection

and emergencies

• Protection against serious hazards, e.g., loss

of lube oil pressure, high exhaust temperature, high bearing vibration

• Testing of steam valves and other important

protective functions

Additional control and monitoring functions

are also required in most applications, such as:

• Monitoring and supervision of a large num

ber of pressures, temperatures, etc., to provide guidance and alarms for operators

• Start-up and monitoring of turbine-generator auxiliaries such as lube oil, hydraulic, and

steam seal systems

• Display, alarm, and recording of the above

functions and data

• Diagnosis of turbine or generator problems

• Health check and diagnostics of the electronic system itself

It is characteristic of the first group of functions

that they must be performed with high control

bandwidth, or with very high reliability, or both, to

ensure long-term reliable operation and service of

the turbine. It is for these reasons that GE has,

from the very beginning of turbine technology,

designed and provided the controls and protection for its units, starting with the MHC systems a

century ago and continuing with the new

SPEEDTRONIC Mark V control system.

For the new all-digital systems, GE has defined

the first group of functions as a “Turbine Unit

Control System." These functions, together with

the input and output devices (I/O) required, are

included in all control systems which are an integral part of steam turbines supplied by GE.

A characteristic of the unit control system is

that all essential turbine control and protection

functions are included to allow a unit to operate

safely even if other supporting systems should fail.

Another characteristic is that the “control point”

interface (i.e., the interface between the turbine

and the control system) remains in GE’s scope,

while interface to plant controls can be made at

“data point” level, which does not include critical

and rapidly varying commands and feedback signals, and therefore, is a more suitable point of

interface to possible non-GE controls. Yet another

characteristic of unit control functions is that they

must be performed either continuously or very

frequently to provide satisfactory control. Data

sampling and processing of control algorithms up

to ten times per second are used for many unit

control functions.

The second group of functions can be performed less frequently (i.e., every few seconds or

more), and turbine operation may be continued,

in most cases, during short-term interruptions in

the monitoring functions as long as the “unit control” is performing correctly.

The second group of functions includes most

of what used to be called “TSI,” for Turbine

Supervisory Instrumentation, which we now prefer to call TGM, for Turbine Generator Monitoring. The TGM functions can be included in the

Mark V systems, or they may be integrated into

the plant control system. For small- and mediumsized units, the TGM functions can be incorporated without significant extra hardware, and for

large units, additional cabinets are needed. These

cabinets can be mounted either at the turbine

and generator or in an equipment room, and they

can interface with a common Mark V operator

interface.

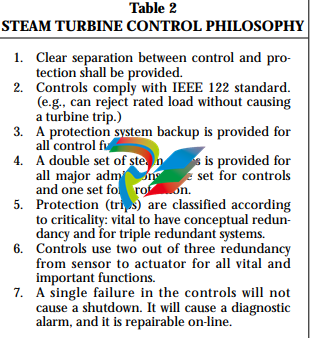

The philosophy applied to steam turbine control systems has developed over time, and it is

summarized in Table 2.

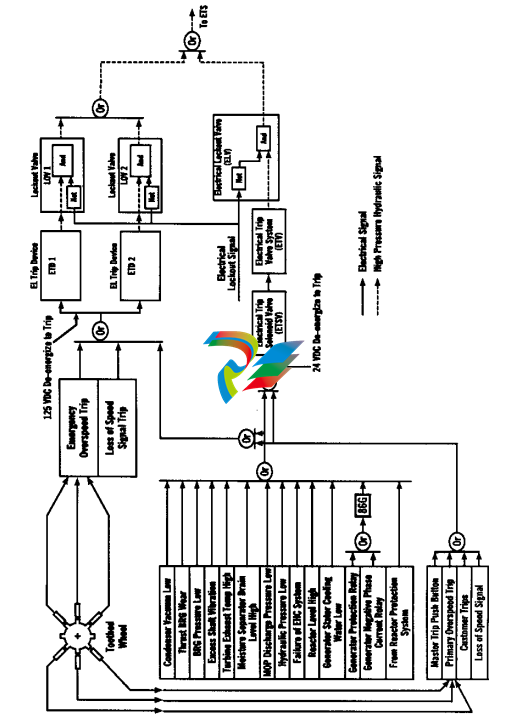

A block diagram of the protective system of the

Mark V is shown in Figure 3. The left-hand side

shows the various trip inputs entering through

redundant paths. At the extreme right is the output to the emergency trip system (ETS), a

hydraulic pressure signal, which will cause rapid

closure of all steam admission valves when depressurized. The critical inputs to the ETS can be tested on-line, one at a time, with the help of the lockout valves located immediately to the left of the

final output to the ETS. This diagram shows the

standard offering with an all-electronic overspeed

trip. Optionally, a system with a mechanical overspeed governor can be supplied.

SPEEDTRONIC MARK V

CONTROL CONFIGURATION

Figure 5 shows the configuration for the

SPEEDTRONIC Mark V triple modular redundant (TMR) control system for a medium to large

steam turbine with redundant operator interfaces.

The core of this system is the three identical controllers called <R>, <S>, and <T>. All critical control algorithms, protective functions, and sequencing are performed by these processors. In so

doing, they also acquire the data needed and generate outputs to the turbine. Protective outputs

are routed through the <P> module consisting of

triple redundant processors <X>, <Y>, and <Z>,

which also provide independent protection for

certain critical functions such as overspeed.

The three control processors, <R>, <S>, and

<T>, acquire data from the triple-redundant sensors as well as from dual or single sensors. A

generic complement of sensors is described in

Table 3. The actual number of sensors will

depend on turbine type. All critical sensors for

continuous controls, as well as protection, are

triple-redundant. Other sensors are dual or single

devices fanned out to all three control processors.

The extremely high reliability achieved by TMR

control systems is due in considerable measure to

the use of triple sensors for all critical parameters,

as it was first demonstrated with the triple-redundant protection system of the EHC Mark II.

MARK V ELECTRONICS

All of the microprocessor-based controls have a

modular design for ease of maintenance. Each

module or controller contains up to five cards,

including a power supply. Multiple processors

reside in each controller which distribute the processing for maximum performance. Individual

processors are dedicated to specific I/O assignments, application software, communications, etc.,

and the processing is performed in a real-time,

multi-tasking operating system. Communication

between the controller’s five cards is accomplished

with ribbon cables and gas-tight connectors. This

eliminates the traditional computer backplane.

Communication between individual controllers is

performed on high-speed Arcnet links.

Figure 4 shows the standard microprocessor

module.

PRIMARY CONTROLLERS

<R><S><T>

The three controllers <R>, <S>, and <T>, shown

in Figure 5, are physically separate and independent modules that contain all control and protection hardware and software. A failure in any of the

three controllers is automatically diagnosed to the

card level and displayed as an alarm message.

Maintenance personnel can power down the

appropriate controller and replace the defective

card while the turbine is on-line. Redundant sensors are used in control and trip protection systems

to provide a “total system” fault-tolerant design. As

a result, diagnostics are able to distinguish between

redundant sensor failures and electronics failures.

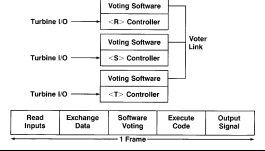

Three basic forms of voting are used in the control. Figure 6 shows how the first form of voting,

the software implemented fault tolerance (SIFT),

works. At the beginning of each computing time

frame, each controller independently reads its sensors and exchanges this data with the data from

the other two controllers. The median value of

each analog input is calculated in each controller

and then used as the resultant control parameter

for that controller. Diagnostic algorithms monitor

a predefined deadband for each analog input to

each controller, and if one of the analog inputs

deviates from this deadband, a diagnostic alarm is

initiated to advise maintenance personnel.

Contact inputs are voted in a similar manner.

Each contact input connects to a single terminal

point and is parallel wired to three contact input

cards in the voted contact input module. Each

card optically isolates the 125 V dc input, and then

a dedicated 80196 processor in each card time

stamps the input to within 1 ms resolution. These

signals are then transmitted to the <R>, <S>, and

<T> controllers for voting and execution of the

application software. This technique eliminates

any single point failure in the software voting system. Redundant contact inputs for certain functions such as low lube oil pressure are connected

to three separate terminal points and then individually voted. With this SIFT technique, multiple

failures of contact or analog inputs can be accepted by the control system without causing an erroneous analog or trip command from any of the

three controllers as long as the failures are not

from the same circuit.

8

F

Figure 6. Software implemented fault tolerance

(SIFT)

A second form of voting is hardware voting of

analog outputs. As illustrated in Figure 7, three

coil servo valves on the steam valve actuators are

separately driven from each controller, and the

position feedback is provided by three LVDRs.

The normal position of each steam valve is the

average of the three commands from <R>, <S>,

and <T>, respectively. The resultant averaging circuit has sufficient gain to override a gross failure

of any controller, such as a controller output

being driven to saturation. Diagnostics monitor

the servo coil currents and the D/A converters in

addition to the LVDRs.

The third form of voting for the trip solenoids

is discussed under OVERSPEED.

OVERSPEED

The <P> protective controller contains three

independent cards <X>, <Y>, and <Z> with their

own processors and power supplies. This separate

set of triple-redundant electronics with its associated three separate speed pickups replaces the

mechanical overspeed governor. <R>, <S>, and

<T> use the first three pickups for speed control

and the primary overspeed protection, while <X>,

<Y>, and <Z> monitor the second set of three

pickups for emergency overspeed protection

(Figure 3).

In addition, the <X>, <Y>, and <Z> cards contain separate relay drivers and magnetic relays that

perform a final contact vote prior to driving the

turbine trip solenoids. Diagnostics monitor the

status of the output ports, relay drivers, and relays

to initiate maintenance alarms if a failure occurs.

Standard on-line and off-line primary and emergency overspeed trip tests are built in to facilitate

testing all hardware and software. Figure 8 illustrates hardware logic voting of an output from

each of three controllers.

SYNCHRONIZING

Automatic synchronization is performed by the

<X>, <Y>, and <Z> cards in conjunction with the

<R>, <S>, and <T> controllers. The controllers

match speed and voltage and issue a command to

close the breaker based on a predefined breaker

closure time. Diagnostics monitor the actual breaker closure time and self-correct each command.

Redundant sets of primary and backup phase-slip

windows eliminate the need for the traditional GXS

synchronizing check relay in the generator control

cabinet. Another feature is the ability to synchronize manually via the Mark V operator interface

instead of using the traditional synchroscope on

the generator protective cabinet. Operators can

choose one additional mode of operation by selecting the monitor mode, which automatically matches speed and voltage, but waits for the operator to

review all pertinent data on the CRT display before

issuing a breaker close command.

POWER LOAD

UNBALANCE – PLU

Large steam turbine applications use another

module similar to <P> which is designated <PLU>

for power load unbalance. This provides power

load unbalance protection and interface to the

fast closing feature on control and intercept valves

via three independent cards <U>, <V>, and <W>.

COMMON I/O <C>

A significant amount of I/O on turbines and

generators is used only for monitoring. This nonredundant I/O is monitored by the <C> module.

For example, thermocouples can be used for control and protection or just for monitoring.

Thermocouples which are used for rotor stress calculations are connected directly to the <R>, <S>,

and <T> controllers, while thermocouples that are

used for monitoring only, e.g., the thrust bearing

oil drain temperature, connect to <C>.

OPERATOR INTERFACE <I>

The interface work station <I> consists of a PC,

color monitor, cursor positioning device, keyboard, and printer. It can be used as the sole operator interface or as a local maintenance work station with all operator control and monitoring

coming from communication links with a plant

distributed control system (DCS). Figure 9 shows

the operator interface schematically.

Operators use the monitor, cursor positioning

device, and keyboard. The keyboard is not necessary. However, the keyboard is convenient for

accessing displays with dedicated function keys

and adjusting setpoints by entering a numeric

value such as 1,000 rpm rather than issuing a

manual raise/lower command. Set point and

logic commands require an initial selection, such

as the command to engage the turning gear,

which is followed by a confirming execute command. The monitor is available in various sizes

and types, and it can be used for desktop mounting, packaged as a drop-in insert for a control

room console, or mounted in a separate freestanding cabinet. The keyboard is primarily used