Honeywell ControlEdge HC900 Communications: Technical Summary

Honeywell ControlEdge HC900 Communications: Technical Summary

Introduction

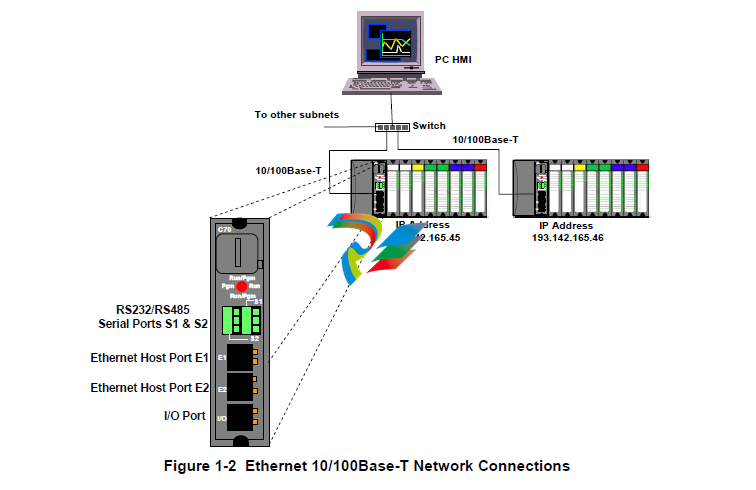

This document summarizes the communication capabilities of the Honeywell ControlEdge HC900 Controller, based on the Communications User Guide (51-52-25-111). The controller is designed to integrate seamlessly with third-party HMI, SCADA, and other host devices primarily through the Modbus protocol, offered over both Ethernet and serial interfaces.

Communication Interfaces

The ControlEdge HC900 controller features three primary communication interfaces, all supporting the Modbus protocol:

Ethernet Port: Provides Modbus/TCP communication over a 10/100Base-T connection.

Serial Port S1: A configurable RS232/RS485 port supporting Modbus RTU.

Serial Port S2: A second configurable RS232/RS485 port supporting Modbus RTU.

Modbus/TCP (Ethernet)

The main network interface uses Modbus/TCP, which encapsulates the standard Modbus RTU protocol within a TCP/IP frame. This allows for robust communication over standard Ethernet networks.

Concurrent Connections: The controller supports multiple simultaneous connections. C30/C50 models support up to 5 concurrent hosts, while the C70/C70R models support up to 10.

IP Addressing: Each HC900 controller requires a unique, static IP address, which must be configured prior to placing it on a network. Configuration is performed using the HC Designer software.

数据格式和双寄存器处理

为了确保与各种主机软件(例如 HMI、SCADA)兼容,HC900 使用可配置的双寄存器格式处理 32 位数据类型(如 IEEE 浮点数)。

主要数据类型:大多数过程数据以 IEEE 32 位浮点数的形式传输。

可配置的字节/字顺序:可以配置 32 位值的字节顺序和字顺序以匹配主机系统的要求。四种可用格式是:

FP B (大端):默认格式。

[Byte4, Byte3], [Byte2, Byte1]FP BB (大端字节交换):

[Byte3, Byte4], [Byte1, Byte2]FP L (小端):

[Byte1, Byte2], [Byte3, Byte4]FP LB (Little Endian Byte-Swapped): (常见于 Wonderware 等许多第三方 HMI)。

[Byte2, Byte1], [Byte4, Byte3]

Modbus Address Mapping

The HC900 offers two methods for mapping internal parameters (like loop PVs, SPs, and outputs) to Modbus addresses:

Fixed Map:

A predefined, structured address map with designated address ranges for specific function block types (e.g., Loops, Setpoint Programmers, Signal Tags).

While easy to use, it has limitations on the quantity of certain blocks (e.g., a maximum of 32 PID loops).

It is the default mapping method available in all firmware versions.

Custom Map:

Available in firmware version 4.0 and higher.

Provides complete flexibility, allowing the user to map any parameter to any Modbus address.

Removes the quantity limitations of the fixed map and allows for the creation of contiguous data blocks for more efficient polling by the host.

Includes additional parameters not available in the fixed map.

Supported Modbus Function Codes

The controller supports a standard subset of Modbus function codes for reading and writing data:

Read Coils (Code 01): Read the status of Digital Outputs.

Read Discrete Inputs (Code 02): Read the status of Digital Inputs.

Read Holding Registers (Code 03): Read data registers (primarily floating-point values).

Read Input Registers (Code 04): Read analog input values directly.

Force Single Coil (Code 05): Write to a single Digital Output.

Preset Single Register (Code 06): Write to a single 16-bit integer register.

Preset Multiple Registers (Code 16): Write multiple registers, required for 32-bit floating-point data.

Loopback Test (Code 08): Diagnostic function.

Report Device ID (Code 17): Reads controller identification and version information.

Conclusion

The Honeywell ControlEdge HC900 controller is a versatile process controller with a robust and flexible communications architecture based on the widely-supported Modbus protocol. Its support for both Modbus/TCP and Modbus RTU, combined with a highly configurable data format and two distinct memory mapping schemes (Fixed and Custom), ensures broad compatibility and efficient integration with a wide array of industrial automation and HMI systems.

.jpg)

.jpg)