Honeywell HC900 Process & Safety Controller: Technical Summary

Honeywell HC900 Process & Safety Controller: Technical Summary

Introduction

This document provides a technical summary of the Honeywell HC900 Process & Safety Controller, a modular and scalable control system designed for a wide range of process control and safety applications. It integrates loop and logic control into a single platform and is certified for use in SIL (Safety Integrity Level) applications. All information is based on the HC900 Process & Safety Controller User and Installation Manual (51-52-25-154).

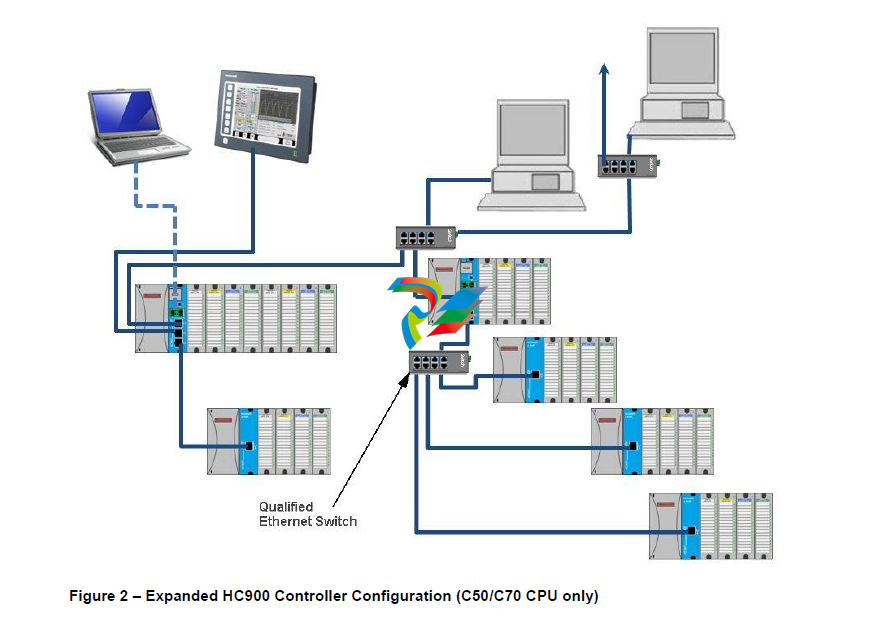

System Architecture & Components

The HC900 system is built on a flexible, rack-based hardware platform that can be tailored to application size and complexity.

Racks: Available in 4, 8, and 12-slot versions to house the CPU, power supplies, and I/O modules.

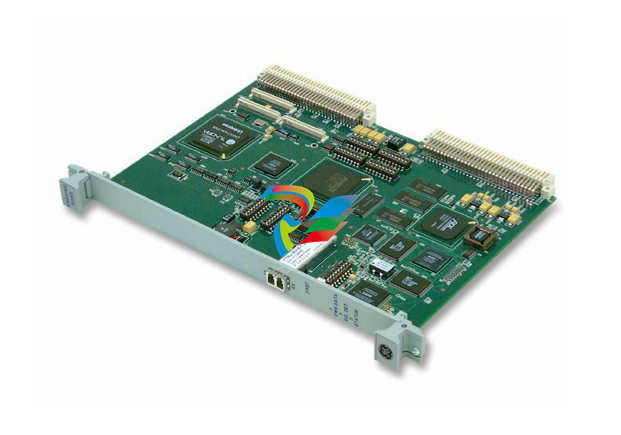

Controller (CPU): The core of the system, available in several models (C30, C50, C70, C75) with varying capacities for function blocks and I/O points. SIL-rated versions (C30S, C50S, C70S, C75S) are available for safety-critical applications.

I/O Expansion: For systems exceeding the capacity of a single rack, I/O expansion racks are used. These racks are connected to the main controller rack via a private, dedicated Ethernet I/O link.

I/O Scanners: Scanner modules (S50/S75) are installed in I/O expansion racks to manage communication between the main CPU and the remote I/O modules. The dual-port S75 scanner is used in redundant systems.

Power Supplies: The system uses modular power supplies (AC or DC input). 8 and 12-slot racks can be configured with redundant power supplies, which requires a Power Status Module (PSM) for monitoring.

High-Availability Redundancy

The HC900 platform is designed for high availability through a robust redundancy scheme.

Redundant CPUs: A redundant controller is built using two C75 CPU modules in a dedicated controller rack. A Redundancy Switch Module (RSM) manages the status of the two CPUs and controls failover.

Automatic Failover: In the event of a failure in the lead CPU, the system automatically and seamlessly transfers control to the reserve CPU. Manual failover can also be initiated.

Redundant I/O Communications: The S75 dual-port scanner enables a redundant I/O network. Each port connects to one of the redundant C75 CPUs, ensuring that communication with I/O racks is maintained even if one CPU or one network path fails.

Redundant Host Communications: The C70 and C75 series controllers feature dual Ethernet ports, which can be configured for redundant connections to supervisory networks (e.g., HMIs, SCADA).

I/O Modules

A comprehensive selection of I/O modules allows the system to interface with a wide variety of field devices:

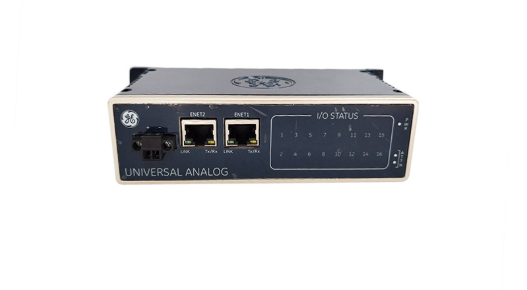

Analog Inputs (AI): Universal AI modules for Thermocouple, RTD, Ohm, mV, V, and mA inputs, as well as high-density, 16-channel high-level AI modules.

Analog Outputs (AO): 4, 8, and 16-channel modules for 0-20mA signals.

Digital Inputs (DI): 16 and 32-channel modules for various signal types, including 24V DC, 120/240V AC, and contact closure.

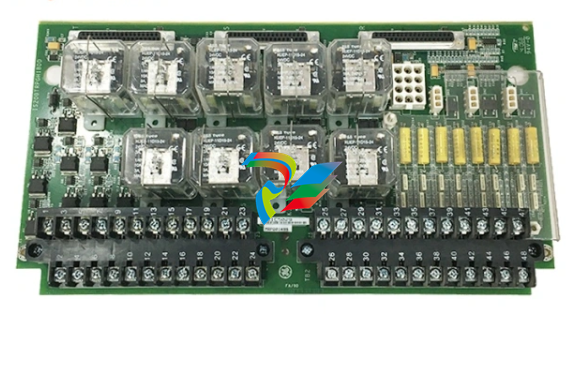

Digital Outputs (DO): Relay, 24V DC Sinking, and 120/240V AC Triac output modules.

Specialty Modules: A Pulse/Frequency/Quadrature (PFQ) module is available for high-speed counting and encoder applications.

Communications

The HC900 offers multiple communication interfaces for system integration and programming:

Ethernet: One or two 10/100Base-T ports support Modbus/TCP for communication with HMIs, OPC servers, and SCADA systems. The Ethernet ports also support peer-to-peer communication (using UDP) with up to 32 other HC900 controllers. For safety applications, use of a firewall is recommended.

Serial Ports: Two galvanically isolated RS-485 ports support Modbus RTU protocol, and can be configured as either a master or a slave.

Configuration: The controller is configured using the HC Designer software, which can connect via Ethernet or a serial port (using an RS-485 to USB converter for newer models).

Safety & Maintenance

SIL Compliance: Specific controller models (e.g., 900C75S) and I/O modules are certified for use in safety-instrumented systems. For safety applications, the controller's mode switch must be in the "RUN" (locked) position to prevent unauthorized changes.

Diagnostics: The system features comprehensive diagnostics, with status indicated by front-panel LEDs and reported to the configuration software and HMI.

Removal and Insertion Under Power (RIUP): All I/O modules are designed to be safely removed and replaced while the rack is powered, minimizing process downtime during maintenance.

.jpg)

.jpg)