GE Digital Energy D20 Analog Input Module

GE Digital Energy D20 Analog Input Module

Overview

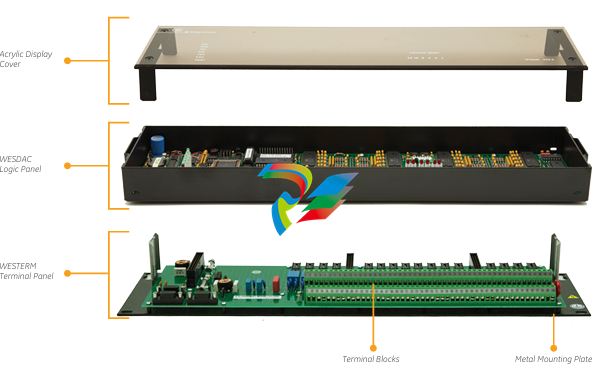

The D20 Analog module is composed of two detachable modules, WESTERM D20 A and WESDAC D20 A.

The bottom module, WESTERM D20 A, is where all field wirings are terminated. The top module, WESDAC

D20 A, processes the data acquired and communicates this to the main D20 processor, see Figure 2.

The WESTERM D20 A is the termination module for the WESDAC D20 A analog input module. All field,

I/O, and power terminations for the WESDAC D20 A are made on the WESTERM D20 A. Up to 32 analog

inputs can be accommodated on compression type terminations. Through the use of input adapter

modules, individual inputs can be configured for voltage or current. Voltage ranges currently accepted

are 1. 5 or 10 volt full scale unipolar or bipolar. Current inputs are sampled via a shunt resistor and

therefore almost any common current range can be accepted. A wetting source is supplied for current

loop inputs.

Capacitors and varistors are equipped to provide Surge Withstand Capability (SWC) as well as impulse

protection on all field inputs. Loop voltage for field transducers can be provided on an individual input

basis. The voltage source can be either the input to the WESDAC D20 A or an external source.

Two DB 9 connectors are provided to allow daisy chaining of the D.20 Link. This link provides the

communication channel over which the main D20 CPU processor, the WESDAC D20 M, can communicate

with the WESDAC D20 A. Power for the WESDAC D20 A is also provided over the same cable assembly.

The power is fused and filtered by passive components on the WESTERM D20 A.

A single DB 9 connector is provided for the WESMAINT D20 maintenance port. This port allows

communications between a VT 100 terminal or emulator, and the WESDAC D20 A. Module input data as

well as diagnostic information can be viewed over the maintenance port. The address jumper block for

the WESDAC D20 A is located on the WESTERM D20 A. The address on the jumper block corresponds to

the module’s address on the D.20 link.

The WESDAC D20 A is physically mounted on and electrically connected to the WESTERM D20 A through

three 40 pin connectors. The two modules are mounted on a 19 inch rack and all field terminations are

wired into the WESTERM D20 A.

Only passive components are mounted on the WESTERM D20 A leaving all the active components on the

WESDAC D20 A. This arrangement simplifies in field repair of the unit since the WESDAC D20 A can be

replaced without disturbing any of the field wiring.

Distributed I/O Architecture

The D20 Remote Terminal Unit (RTU) design is based on a distributed

processing architecture including real-time data acquisition and control

software. These I/O modules can be located close to the primary equipment

being monitored and controlled as they receive and send data back to the

master D20 main processor.

The I/O modules are intelligent modules that contain on-board

microprocessors and are configured as slave devices to the D20 main

processor. In the Figure 1 pictorial setup, specific I/O processing is distributed

throughout the D20 RTU to the appropriate I/O modules.

The I/O modules support two communication protocols: (1) DNP 3 protocol,

and (2) high speed, high-level data link controller (D.20 Link, HDLC) protocol.

The peripheral modules have serial communication ports and various types

of field connections.

The hardware construction of each remote I/O module type is similar (see

Figure 2.)

Data Processing

D20 I/O peripherals provide specialized processing and storing/buffering

functions for analog inputs/outputs by gathering data from field sources or

acting as an output unit to interface with field devices.

I/O processing provides flexible, reliable, robust operation and is configurable

on a per-point or per-system basis.

The D20A is capable of processing standard voltage and current inputs

continuously. It supports the following:

• Programmable Input Ranges: A programmable gain instrument amplifier

permits programming of voltage input ranges. Ranges are stored in RAM

on a per-point basis. (+/- 1. +/-5. +/- 10 V scale).

• Variable Scan Rate: Programmable scan rate from 17.2 to 20.5 ms (50/60

Hz) on a per module basis.

• 32 Differential Analog Inputs and eight internal references using

synchronous integrating-type analog-to-digital (A/D) converters.

• A/D Conversion provides excellent normal-mode rejection characteristics

while maintaining very good response times (approximately 550 ms total).

Termination Types

D20 Analog I/O module can be ordered with the following field termination

options:

| User name | Member Level | Quantity | Specification | Purchase Date |

|---|