Foxboro E69F Current-to-Pneumatic Signal Converter

E69F Current-to-Pneumatic

Signal Converter

Introduction

General Description

TheE69F Current-to-Pneumatic Signal Converter (Figure 1) is a field-mounted instrument that

transforms a dc milliampere input signal to a proportional pneumatic output signal.

This output signal can be used either to operate such pneumatic devices as dampers, and valve

actuators, and so forth, or as the input to various pneumatic instruments.

Principle of Operation

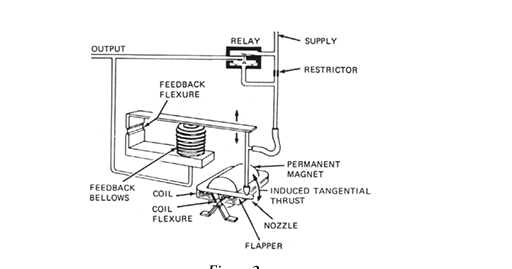

A dc milliampere input signal is converted to a proportional pneumatic output signal in the fol

lowing manner (see Figure 2). A coil positioned in the field of a permanent magnet reacts to the

current by producing a tangential thrust proportional to the input signal flowing through it. The

thrust, acting through coil flexures, varies the gap between a flapper and a nozzle. This causes a

change in the output pressure of the relay, which is also the converter output pressure. This pres

sure is fed to a feedback bellows which exerts a force on a feedback flexure to move the nozzle and

establish a throttling relationship between the flapper and the nozzle

Standard Specifications

Input and Output Ranges

Input Ranges (mA)

kPa

Output Ranges(3)

4 to 20(1)

or

20 to 100

40 to 200

7 to 125

7 to 220

psi

3 to 15

3 to 27

6 to 30

1 to 18

1 to 32

10 to 50(2)

(1) 4 to 12 or 12 to 20 mA. Split ranges available with addition of a flat spring.

(2) 10 to 30 or 30 to 50 mA. Split ranges available with addition of a flat spring.

(3) Direct or reverse, as specified.

NOTE

Ranges are listed in kPa and psi. For alternative ranges in kg/cm2 or bar, divide

applicable kPa values by 100.

Supply Pressure

Nominal

140 kPa or 20 psi

Limits

130 and 160 kPa or 19 and 23 psi

240 kPa or 35 psi

225 and 260 kPa or 33 and 38 psi

Supply pressure must not be less than 20 kPa or 3 psi above the maximum signal.

Input Resistance

4 to 20 mA Input: 170 Ω

10 to 50 mA Input: 27 Ω

Air Consumption

20 to 100 kPa or 3 to 15 psi output:

40G Relay: 0.5 m3/h (0.30 cfm) at standard conditions.

All other outputs: 40D Relay:

1.3 m3/h (0.75 cfm) at standard conditions with 140 kPa or 20 psi supply.

1.7 m3/h (1.0 cfm) at standard conditions with 240 kPa or 35 psi supply.

Ambient Temperature Limits

Normal Operating Conditions:-30 and +60°C (-20 and +140°F)

Operative Limits: -40 and +80°C (-40 and +180°F)

Calibrated Accuracy

±0.5% of span; but ±2% of span with output signals of 7 to 125 and 7 to 220 kPa or 1 to 18

and 1 to 32 psi

Mass

(Approximate) 2.3 kg (5 lb)

Product Safety

For electrical classification of converter, refer to data plate. For conditions of certification, refer to

Calibration

For simplicity, the procedure below assumes a converter with a 4 to 20 mA input and a 20 to

100 kPa or 3 to 15 psi output. For other ranges, substitute the applicable values. The specific

input and output are listed on the converter data plate.

Equipment Setup

Calibration setup is shown in Figure 7.

Any adjustment to the span will interact with the zero adjustment and will change

the initial zero setting. Therefore, any adjustment made to the span must be

followed by readjustment of zero.

1. Set up equipment as shown in Figure 7.

2. Apply 12 mA (50%) input to converter and adjust output (zero screw) to 60 kPa or

9 psi (50%). See Figure 8.

3. Apply 20 mA (100%) input to converter and note amount of error above or below

100 kPa or 15 psi (100%) output. If error is greater than ±2% (1.6 kPa or 0.025 psi),

perform Step 4. If error is less than ±2%, proceed to Step 5.

4. Loosen 5/16-inch bellows locknut. Note reference line on bellows. Rotate bellows1 so

that reference line moves toward motor to decrease span or away from motor to

increase span until the error is within ±2%. Tighten bellows locknut.

Repeat Steps 2 and 3.

5. See Figure 9. Loosen the 5/16-inch span locknut and turn the 5/16-inch span

adjustment nut a proportional amount (noted in Step 3) based on the following: 1/6

of a turn (point to point on the hexagonal nut) corrects the error by 0.5%.

7. Apply 12 mA (50%) input to converter and adjust output (zero screw) to 60 kPa or

9 psi (50%).

8

8. Apply 20 mA (100%) input and check output for 100 kPa or 15 psi (100%). If

output is not correct, repeat Steps 5 through 7.

9. Apply 4 mA (0%) and check output for 20 kPa or 3 psi (0%). If necessary, readjust

zero screw for correct output.

10. Apply 100% input and check output. If output is not correct, repeat Steps 5 and 8

until both 0% and 100% outputs are correct.

Maintenance

Relay Maintenance

To Remove Relay

Remove the two large screws and pry off relay. See Figure 11. A gasket is supplied with each

replacement relay.

For maintenance details, see Instruction MI 011-493 (Model 40G) or MI 011-491 (Model 40D).

To Clean Restrictor

Remove relay. See “To Remove Relay” procedure.

Clean by inserting a 0.1 mm (0.005 in) diameter wire (or Foxboro cleaning wire, Part 0042527)

through

t up equipment as shown inFigure 77. 2. Apply 12 mA (50%) input to converter and adjust output (zero screw) to 60 kPa or 9 psi (50%). SeeFigure 88.

3. Apply 20 mA (100%) input to converter and note amount of error above or below 100 kPa or 15 psi (100%) output. If error is greater than ±2% (1.6 kPa or 0.025 psi), perform Step 4. If error is less than ±2%, proceed to Step 5.

.png)

.png)