Foxboro E69F Current-to-Pneumatic Signal Converter

Figure 8.

4. Loosen 5/16-inch bellows locknut. Note reference line on bellows. Rotate bellows1 so that reference line moves toward motor to decrease span or away from motor to increase span until the error is within ±2%. Tighten bellows locknut.

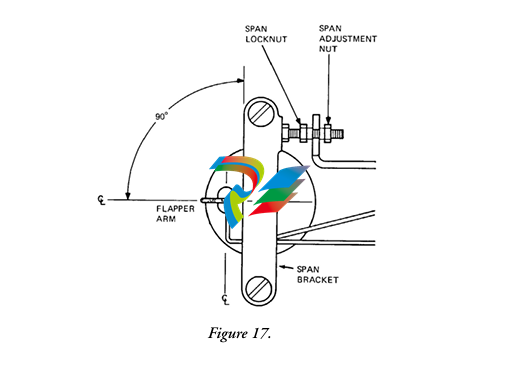

Repeat Steps 2 and 3. 5. SeeFigure 99. Loosen the 5/16-inch span locknut and turn the 5/16-inch span adjustment nut a proportional amount (noted in Step 3) based on the following: 1/6 of a turn (point to point on the hexagonal nut) corrects the error by 0.5%.

1. Bellows Assembly is on an eccentric.

7

MI 018-430 – June 2005

CAUTION

The span locknut must be loosened prior to span adjustment. Do not force nuts against each other to make small span changes. Forcing nuts together could result in

stripping of threads.

6. Disregard output changes that occur when span adjustment is made. Tighten span locknut.

CAUTION

Do not overtighten span locknut when locking in place as threads could become

stripped.

Figure 9.

Figure 10.

7. Apply 12 mA (50%) input to converter and adjust output (zero screw) to 60 kPa or 9 psi (50%).

8

MI 018-430– June 2005

8. Apply 20 mA (100%) input and check output for 100 kPa or 15 psi (100%). If output is not correct, repeat Steps 5 through 7.

9. Apply 4 mA (0%) and check output for 20 kPa or 3 psi (0%). If necessary, readjust zero screw for correct output.

10. Apply 100% input and check output. If output is not correct, repeat Steps 5 and 8 until both 0% and 100% outputs are correct.

Maintenance

Relay Maintenance

To Remove Relay

Remove the two large screws and pry off relay. SeeFigure 1111. A gasket is supplied with each replacement relay. For maintenance details, see Instruction MI 011-493 (Model 40G) or MI 011-491 (Model 40D).

CAUTION

If converter is equipped with explosionproof cover, three flame arresters are present.

Arresters must remain in place for explosionproof protection.

Figure 11.

To Clean Restrictor

Remove relay. See“To Remove Relay” procedure.

Clean by inserting a 0.1 mm (0.005 in) diameter wire (or Foxboro cleaning wire, Part 0042527) through orifice.

9

MI 018-430 – June 2005

Converter Modifications

NOTE

Foxboro does not consider the following modifications a field conversion. They are considered factory modifications due to the complexity of the procedures and the large amount of time required to perform them. If the modifications must be made in the field, use the following procedures and contact Foxboro for additional

assistance.

To Reverse Converter Action

The existing action of the converter is indicated by the marking on the exposed top of the motor cover: INC-INC (increasing input produces an in

creasing output), or INC-DEC (increasing

input produces a de

creasing output). When reinstalling the motor (Step 9 below), the exposed marking on the motor cover must indicate the desired action. 1. Disconnect instrument from installation (input wiring, air lines, and mounting bolts). 2. Remove two screws holding span bracket. SeeFigure 1212.

Figure 12.

3. Remove two screws holding feedback assembly (with bellows). Note routing of tubing for later replacement.

NOTE

Do not remove mounting plate from feedback assembly. Remove as a unit.

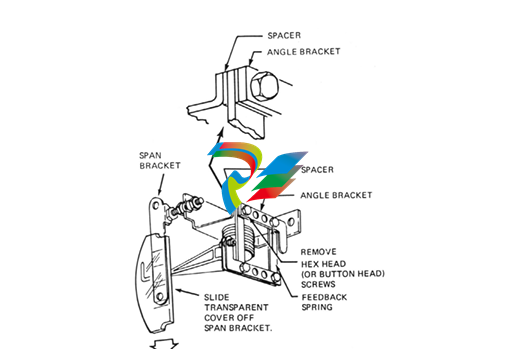

4. Lift aside feedback assembly (do not damage nozzle) to expose spring on bottom of case. Slide transparent cover off span bracket as shown inFigure 1313. Unhook spring from motor bracket.

(For convenience, feedback assembly can be removed entirely by disconnecting tubing. Note identification of tubing for later reconnection.)

10

MI 018-430– June 2005

5. On feedback assembly, remove two hex head (formerly buttonhead) screws. Interchange locations of angle bracket and spacer. SeeFigure 1313.

Reinstall hex head screws and tighten to a torque of 3.4 to 4.0 N•m (30 to 35 lb•in). Switching locations of angle bracket and spacer allows the Ni-Span angle bracket to correct for temperature induced errors in the INC-DEC mode.

Figure 13shows parts in INC-INC arrangement.

Figure 13.

6. Remove hex columns (use 5/16-inch wrench), and lift off motor pivot plate. SeeFigure 1212.

7. Lift out motor. Carefully lift flapper straight up from flapper arm on motor. Do not deform flapper. Holding on to flapper arm on other end of motor while removing will prevent internal motor flexure deformation.

8. Remove two screws holding bracket to bottom of motor. SeeFigure 1414. Invert motor and reinstall bracket (on side of motor that was formerly on top).

11

MI 018-430 – June 2005

Figure 14.

9. Wind excess wire clockwise around motor and carefully place motor into position in the case assuring that bottom arm is

.png)

.png)