Woodward CPC-II Current-to-Pressure Converter

CPC-II

Current-to-Pressure Converter

Applications

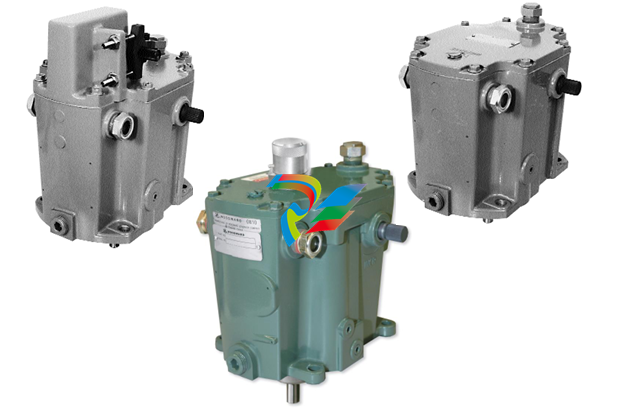

The CPC-II (current to pressure

converter, generation II) is an

electrohydraulic pressure-regulating

valve control designed for use in

positioning single-acting steam turbine

valve servos. This CPC’s superb

accuracy and resolution make it ideal

for steam turbine valve control and

related turbine speed and load

control. The CPC accepts a 4–20 mA

pressure demand signal and

accurately controls oil pressure to

precisely position single-acting steam

turbine governor-valves. Precise and

stable steam valve control directly

relates to improved steam turbine

speed and load control and reduced

system mechanical wear.

The CPC’s redundancy features make it ideal for critical steam turbine applications,

where turbine up-time and availability are essential. This converter can be configured to

accept redundant pressure demand inputs, from one or two (redundant) controllers, and

vote the input to follow. Alternatively the CPC can be configured to accept signals from

both its internal oil pressure sensor and an external (redundant) oil pressure sensor, and

use the voted healthy signal.

The CPC’s robust design (strong actuator, corrosion-resistant material, single moving

rotary valve, and self-cleaning port design) makes it ideal for challenging applications

where dirty or contaminated oil may be present.

• Oil contamination

resistant

• Precise fluid

pressure control

• Stable & linear valve

control

• Included valve

linearization table

• Redundant

inputs/sensors for

critical applications

• Accepts signals

from redundant

controllers

• Redundant (dual)

CPCs

(Master/Slave)

functionality

• Standard mounting

and hydraulic

connections

• Self cleaning valve

algorithm

• Status & health

indication

Optionally two controllers can be connected to a single CPC in a redundant Master/Slave

fashion to allow the turbine to continue to operate if either turbine control fails, or on-line

changes are desired. Designed for use in applications requiring full redundancy,

optionally two CPCs can be applied in a dual-redundant fashion, simplifying the entire

system and control wiring.

Description

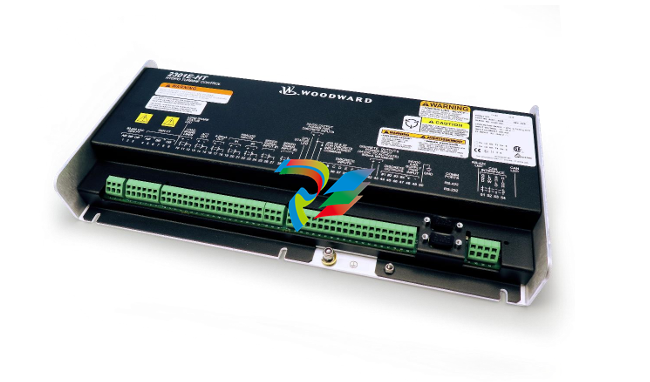

The CPC is an electrohydraulic pressure-regulating valve control that utilizes a very

accurate internal pressure sensor and PID controller to precisely control steam turbine

valves. The CPC consists of a valve-actuator assembly, pressure sensor, and electronic

driver module. The unit’s driver module accepts one (or two) 4–20 mA pressure setpoints

and compares these setpoints to the sensed oil pressure, to accurately control turbine

valve oil pressure.

The CPC controls oil pressure by porting supply-oil to its control-oil output port (turbine

valve control oil) or back to the system supply tank. This converter’s special PID

architecture allows it to perform very stable pressure control during normal conditions,

and respond in milliseconds to desired valve step changes during system or plant

transients. As a means of protecting the turbine, an internal valve-return-spring forces the

CPC to a failsafe position (port oil to drain) and safely close turbine control valves upon

any internal unit failure (electrical input power failure, pressure sensor failure, processor

failure, etc.).

The CPC is factory and/or field configurable via a computer

based service tool. The CPC’s PCI Service Tool uses a simple

user-friendly format to allow users to easily configure,

calibrate, and adjust all internal functions and PID control

settings. The CPC includes a 4–20 mA output channel to

indicate control oil pressure level, and unit alarm and shutdown

relay outputs for use as unit health and status indications into

the system controller or plant DCS.

A Manual Stroke function allows users to manually stroke the

CPC output pressure (turbine valve position) locally at the

unit, via an internal Manual Stroke Screw. This local manual

stroke function is designed with built in security logic to

protect the users from un-intentional use of this function

during normal operation. Manual Stroke capability is also

available via remotely or locally via the CPC’s computer

based PCI Tool.

Since flow through single and staged inlet steam valves tend

to be non-linear throughout their flow range, turbine controls

are typically de-tuned to compensate for instability or

sluggish control points throughout this range. As a way of

allowing turbine control optimization, the CPC includes an

eleven-point linearization table to allow turbine OEMs or

users to compensate for poor valve linearization by digitally

linearizing the control to valve flow relationship.

Because many turbine users utilize redundant pressure

converters to increase system reliability, and because these

type of applications are prone to silting build-up problems in

the slave unit, a special “Silt Buster” (patent pending) routine

is also configurable to routinely remove internal silt build-up.

Accessories

A standard steel adapter plate is available to allow the CPC

to easily interface with systems designed for Voith I/H

converters.

Specifications

Performance

Accuracy: < ±0.2 % of full range

Repeatability: 0.1 % of full range

Temperature Drift: < ±0.01 % of full range /°C

Pressure stability: < ±2 % of setpoint

.png)

.png)