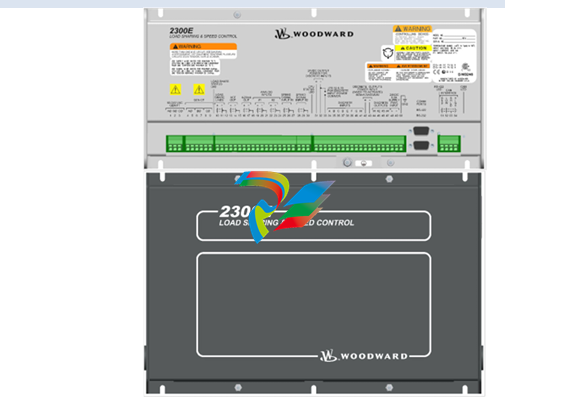

Woodward easYgen-3000 Genset Control for

easYgen-3000

Genset Control for

Multiple Unit Operation

The easYgen-3000 is a control unit for genset management applications. The numerous inputs and outputs,

along with a modular software structure, permit you to use the easYgen-3000 for a wide range of applications

with only a single part number. This includes stand-by, AMF, peak shaving, import-export, cogeneration or

distributed generation, among others. Also the easYgen-3000 is compatible for island, island parallel, mains

parallel and multiple unit mains parallel operations.

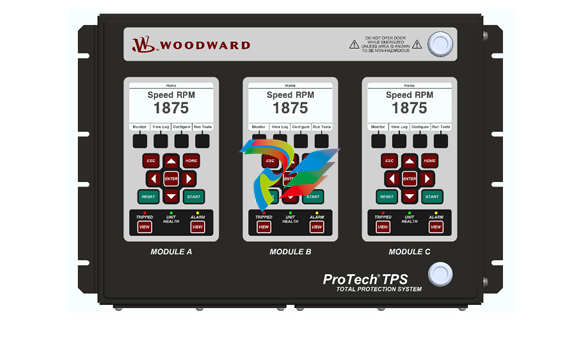

The easYgen-3000 is able to control up to 32 gensets connected in a network with automatic sequencing.

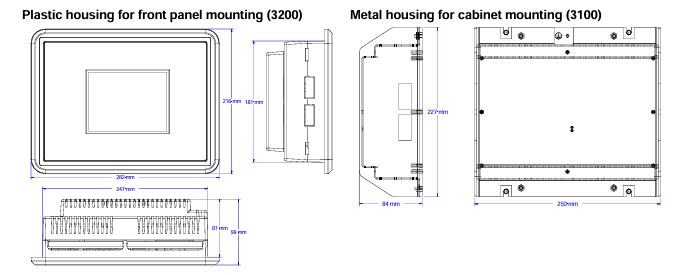

The easYgen-3000 is available in two variants, the easYgen-3100 for cabinet back panel installation, and the

easYgen-3200 with graphical display and soft keys for front panel mounting.

FlexAppTM – This feature provides the tools to easily configure the number of operated breakers: None, GCB,

GCB and MCB.

LogicsManagerTM – Woodward's LogicsManager software enables to change the operation sequences and

adapt them to specific needs. The LogicsManager accomplishes this by monitoring a range of measuring val

ues and internal states, which are combined logically with Boolean operators and programmable timers. This

enables to create and/or modify control and relay functions.

FlexInTM – The analog inputs are configurable to operate with VDO, resistive, and/or 0 to 20 mA senders.

Flexible Outputs – Speed and voltage bias outputs are configurable to function with all speed governors and

voltage regulators. The outputs can also be used as freely scalable outputs (e.g. for driving external meters).

FlexCANTM – Advanced network interfaces ensure unsurpassed control performance – from engine control up

to total plant operation. The easYgen-3000 is capable of working with all common industrial interfaces, includ

ing CAN, RS-232. and RS-485. The multiple communication protocols permit the easYgen-3000 to communi

cate with a vast majority of engine control units (ECUs), external I/O boards, PLCs, and modems. CANopen,

J1939. Modbus RTU, and Modem protocols are supported.

DynamicsLCDTM – The adaptive and interactive 5.7", 320x240 pixel graphical LC display with soft keys and a

clear menu structure ensures intuitive user operation and navigation.

Features

• Operation modes: Auto, Stop, Manual, and Load/No Load test modes via discrete input possible

• Breaker control: Slip frequency / phase matching synchronization, open-close control, breaker monitoring

• Load transfer features: open / closed transition, interchange, soft loading / soft unloading, mains parallel

• Process and load-dependent start/stop logic for diesel and gas engines programmable for spinning or system

reserve with fixed or dynamic priorities.

• Real and reactive power load sharing with up to 32 units

• Remote control via interface and discrete/analog inputs for adjusting speed, frequency, voltage, power, reactive

power, and power factor set points

• Complete integrated engine and generator protection as well as mains monitoring features

• Freely configurable PID controllers for various control purposes, such as heating circuit control (CHP applica

tions), water level, fuel level, or pressure and/or other process values

• Special Scania S6. MTU ADEC, Volvo EMS2 & EDC4. Deutz EMR2. MAN MFR/EDC7. SISU EEM and Wood

ward EGS02 ECU support (depending on Package)

• Counters for operating hours / engine starts / maintenance / active energy / reactive energy

• Configurable trip levels / delay timers / alarm classes for monitoring and protective functions

• Clear text display and evaluation of up to 100 J1939 analog values

• Discrete and analog I/O expansion board connectivity (Woodward IKD 1 or Phoenix Contact IL series)

• Front panel and PC configurable (ToolKit software)

• Multi-level password protection for access via HMI or interface

• Multi-lingual capability (English, German, French, Spanish, Chinese, Japanese, Italian, Portuguese, Turkish, Russian)

• Peak shaving operation

• Stand-by operation

• AMF operation

• Cogeneration (CHP)

• Isolated & mains parallel

operation

• Import/export control

• Soft loading features

• Open/closed transition

• Load sharing and load

dependent start/stop for

up to 32 units

• Programmable operation

sequences

• Multi-lingual capability

• CANopen / J1939 ECU

Control

• Modbus RTU Protocol

• CE marked

• UL/cUL Listing

• LR & ABS Marine Ap

provals

• Event recorder (300 events, FIFO) with real time clock

Power supply .......................................................... 12/24 Vdc (8 to 40 Vdc)

Intrinsic consumption .................................................................. max. 17 W

Ambient temperature (operation) ....................... -20 to 70 °C / -4 to 158 °F

Ambient temperature (storage) ........................ -30 to 80 °C / -22 to 176 °F

Ambient humidity ...................................................... 95 %, non-condensing

Voltage ............................................................................................... ( /Δ)

100 Vac [1] Rated (Vrated) ............................................ 69/120 Vac

Max. value (Vmax) ........................................... 86/150 Vac

.png)

.png)