Woodward 8290-189-EPG-installation-manual 8290-044

8290-189-EPG-installation-manual 8290-044

Installation and Operation Manual

This manual covers Electrically Power Governor (EPG) models 512/524 and

1712/1724. Refer to the appropriate manual or contact Woodward for information

about other versions of the EPG.

Application

The EPG is used to control the speed of diesel, gas, and gasoline engines. It can

also control the speed of gas turbines. Installation of EPG actuators is simple

because they require neither mechanical drive nor hydraulic supply.

The EPG handles prime movers with mechanical loads and generator loads

equally well. Generator sets which will be paralleled, however, require additional

appropriate switch gear, current and potential transformers, and the Woodward

Generator Load Sensor.

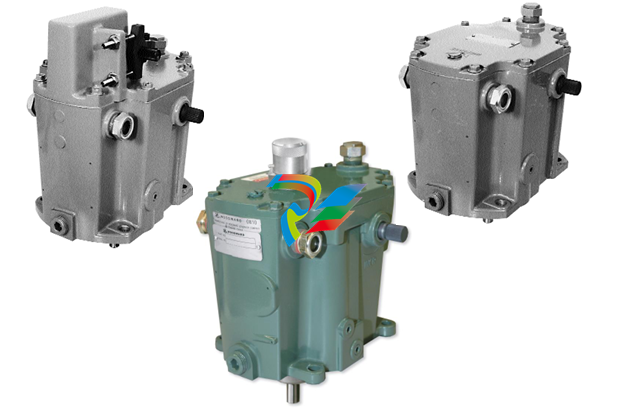

An EPG is a three-component system, requiring a magnetic pickup, speed

control, and actuator.

A battery charger must be used to keep the battery charged. Maximum steady

state current consumption is 4 A for the 12-volt models (512/1712), and 3 A for

the 24-volt models (524/1724).

Part Number Selection

Use EPG Model 512/1712 for operation in 12-volt systems. Use Model 524/1724

for operation in 24-volt systems.

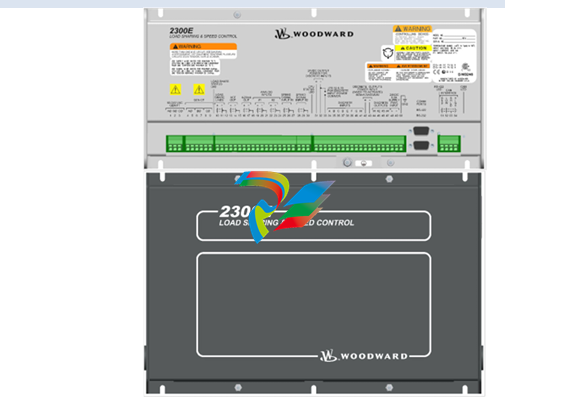

Additionally, speed controls are available for four ranges of magnetic pickup

frequencies, for diesel engines and gas turbines, or for gasoline and gas

engines. Actuators have a double-ended output shaft for either clockwise or

counterclockwise rotation to increase fuel.

Speed controls and actuators must be compatible. Use the Part Number

Selection Table below (Table 1-1) to choose compatible EPG speed controls and

actuators.

The optional Start Fuel Limit feature allows setting a maximum actuator position

during start-up. The maximum position remains in effect until the engine reaches

the selected idle or rated speed. The limit may be adjusted out of the way by

turning the adjustment potentiometer fully clockwise.

The Dual Dynamics feature allows tailoring a special set of responses for

unloaded and loaded operating conditions. This type of control is often needed

for gas engines and other systems with non-linear fuel systems. A switch is used

to change between slow and fast dynamics.

Accessories

This manual includes some information about accessories frequently used with

EPGs.

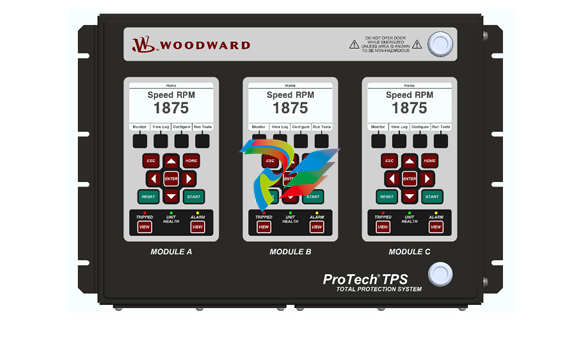

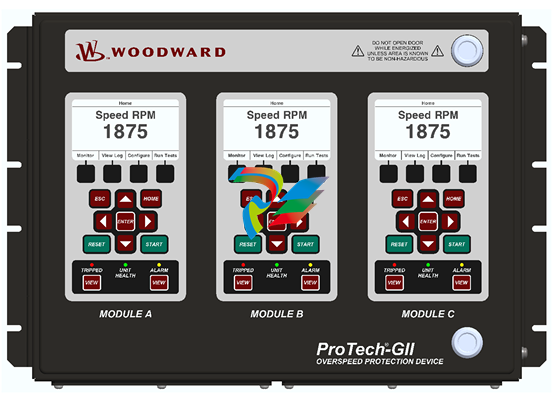

To Parallel Generators

Add the Generator Load Sensor to the EPG in paralleled generator applications.

Woodward makes many accessories for paralleled generator applications.

To Decrease Acceleration and Deceleration

The Ramp Generator or an optional, external capacitor can be used to increase

the time to go from idle to rated speeds and vice versa. The Ramp Generator

provides a linear ramp with times adjustable to 25 seconds in a typical case. It is

useful in smoke-limiting applications. Use the 8271-909 with 24 V batteries and

the 8271-910 for 12 V batteries. The capacitor provides an exponential ramp with

times up to four seconds. Exponential means it changes (speed in this case)

rapidly at first but slows as it approaches its final value. See the typical wiring

diagram for capacitor requirements.

References

These publications can be obtained from your Woodward authorized Distributor

or AISF (Authorized Independent Service Facility). All are also available on the

Woodward website (www.woodward.com).

Catalog

52122

Product

Specification

04106

Manual

25070

82510

Title

Woodward Industrial Control Product Line Catalog

Title

Model 512/1712 & 524/1724 Electrically Powered Governors

Title

Electric Governor Installation Guide

Magnetic Pickups for Electric Governors

direction of rotation for increased fuel by choosing a suitable linkage.

If you are using a Woodward supplied installation kit, follow its instructions and

skip over Linkage Compatibility. Begin again with Installing the Magnetic Pickup.

Linkage Compatibility

Also match linkage linearity to the fuel control. Use a linear linkage as shown in

Figure 2-2 unless the prime mover has a carburetor or other non-linear fuel

control. See Figures 2-3 and 2-4 for a carburetor compensating linkage. Contact

Woodward if a linkage different from those shown is required. Incorrect linearity

matching can cause stable operation at some fuel settings but oscillation at other

fuel settings.

A return spring is included in the actuator. Do not use an additional return spring.

(Low force return springs that may be located in an engine’s valve cover usually

don’t affect EPG performance.)

Make sure that the actuator is capable of moving the fuel control to the maximum

and minimum limits. Let the fuel control limit actuator travel. Set the linkage so

that the actuator is just above minimum when the fuel control is at its minimum

stop and (except for Detroit Diesel engines) so that the actuator is just below

maximum when the fuel control is at its maximum stop. We recommend that

Woodward installation kits be used for Detroit Diesel engines.

Use good rod end connectors. The link connecting the actuator lever to the fuel

control lever must not be so long that it flexes when the prime mover is running.

Installing the Magnetic Pickup

Mount the magnetic pickup through a housing or rigid bracket. Make sure that

the sensed gear is of magnetic material. The gap between the pickup and the

.png)

.png)