Woodward 8290-189-EPG-installation-manual 8290-044

outside diameter of the gear should be set to approximately 1.0 mm (0.04”) at the

closest point (radial runout). Using the pickup with small gears may require

spacing as close as 0.25 mm (0.010”).

If you cannot measure the gap directly, it can be set in this manner: with the

prime mover shut down, turn the pickup in (clockwise) until it touches the outside

diameter of a tooth. Then back out the pickup (counterclockwise) approximately

three-quarters of a turn. Run the gear slowly through 360 degree rotation to

check the clearance of the pickup. When the gap is set, tighten the jam nut

securely against the housing or bracket.

The standard pickup models require mating connectors, MS 3102R-18-3P. The

connectors are not furnished with the pickup, but may be ordered from

Woodward if desired. See manual 82510. Magnetic Pickups and Proximity

Switches for Electronic Controls, for more information

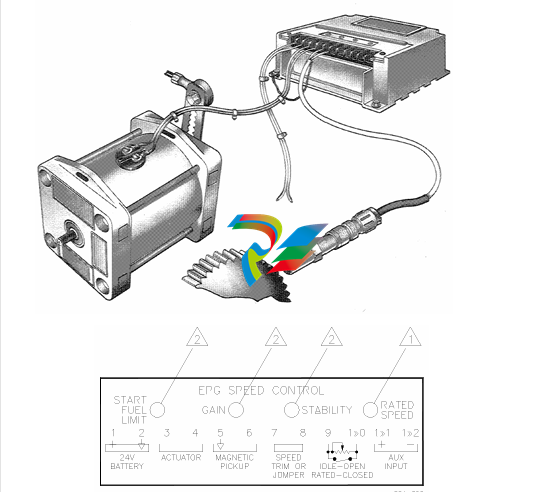

Wiring Instructions

Use a wiring diagram for the specific part number of your EPG system to make

all wiring connections. The wiring diagram is available from Woodward. Typical

wiring is shown in Figure 2-5.

Make all connections using insulated terminals. The wiring from actuator to

speed control and from the battery to the speed control must be as short as

possible. Maximum wiring lengths are:

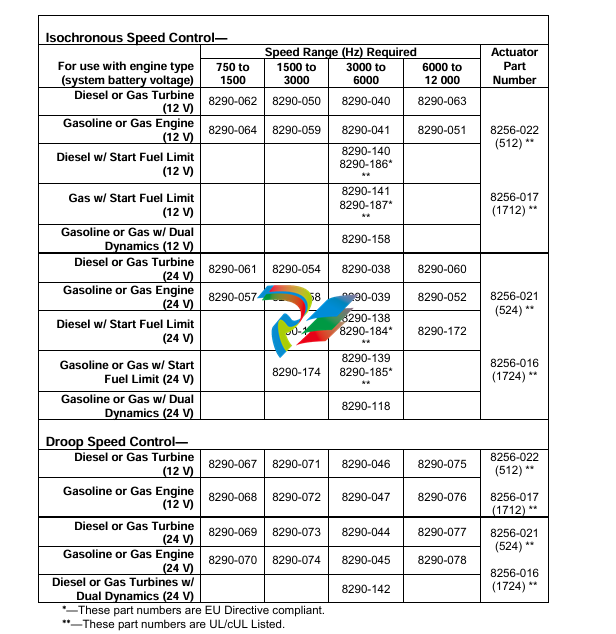

Maximum Wiring Length Chart

EPG Model

14 AWG

(2 mm²)

Maximum Wire Length

12 AWG

(3 mm²)

512/1712

10 ft (3 m)

524/1724

20 ft (6 m)

35 ft (11 m)

75 ft (23 m)

The fuse and switch or circuit breaker must be in the non-grounded battery lead.

Use a fuse or circuit breaker as specified in the Switch and Fuse Requirements

Chart. Do not use a fuse of higher current rating. Starter relays make good EPG

power switches.

Installation Checks

Checks for all Applications

The following steps check only the speed control and actuator, which must work

correctly before paralleling the generator. Since most faults appear when the

prime mover is first run, this step-by-step approach eliminates most problems

before they occur. The main part of Chapter 5 (Troubleshooting) is doing these

checks.

If a Load Sensor is used, temporarily remove the wires at speed control terminals

11 and 12 and temporarily jumper terminals 11 to 12. The generator must not be

paralleled during these tests. If a Ramp Generator is used, temporarily remove

the wire at speed control terminal 10. If a capacitor is connected to terminal 10 to

provide a ramp between unloaded and loaded, it must be removed during this

test or calibration. Leave the idle-rated switch wiring connected. Do the checks in

the order indicated. Terminal numbers in this section refer to the speed control.

Check that all electrical connections are correctly made and terminal screws

are tight; the magnetic pickup is properly installed and the jam nut is tight;

the actuator and linkage are securely fastened. If start-fuel limit is present,

turn the adjustment fully clockwise during these tests. If dual dynamics are

present, set the switch closed for slow dynamics.

2. Do not start the prime mover now. Turn on governor power. If the fuse or

breaker opens as soon as power is applied, the battery polarity (terminals

14 and 15) is probably reversed. The actuator shaft can jump when power is

turned on, but must quickly come back to the minimum fuel position. Check

the battery voltage at terminal 1 (+) and 2 (–). It must be from 10 to 16 Vdc

for 512/1712 controls, and from 20 to 32 Vdc for 524/1724 controls.

Disconnect any wiring or jumper on terminal 7. Measure 7.2 ±1.0 V from

terminal 2 (–) to 7 (+) [terminals 2 (–) to 9 (+) for dual-dynamics control].

Reinstall the wiring to terminal 7 if voltage is correct. Do not use the control

if voltage is incorrect.

If idle speed is desired, connect a 50 kΩ potentiometer or fixed resistor to

terminals 9 and 10 as shown in the typical wiring diagram. To calculate the

value of a fixed resistor:

R = 17 kΩ

( Rated Speed

Idle Speed – 1 )

Put the idle-rated switch in the rated position or jumper terminals 9 and 10.

Measure the voltage from terminal 7 (+) to 2 (–). Put the idle-rated switch in

the idle position or remove the jumper. The voltage must increase. If it does

not increase, check the speed trim pot, if used, and the idle-rated switch

wiring.

If a signal generator with an isolated output is available, the failsafe and

actuator travel can be checked, Rated and idle speed can be preset. If a

signal generator is not available, skip to step 7.

Turn off governor power. Remove the magnetic pickup wires from terminals

5 and 6. Connect the signal generator to terminals 5 and 6. Set the output

between 2 and 10 Vrms. The wave form can be sine, square, or triangular.

Calculate the MPU frequency for idle and rated speeds (see part number

selection in Chapter 1).

Check Failsafe and Actuator Travel:

Set the signal-generator frequency to about half of idle speed. Set the idle

rated switch to rated. Turn the signal generator and governor power on. The

linkage must be at the maximum-fuel position. Except for Detroit Diesel

engines, verify that linkage travel is limited by the prime-mover fuel control,

not by the actuator stop. Turn the signal generator off and remove the

connections at terminals 5 and 6. The linkage should move to the minimum

.png)

.png)