Woodward CPC-II Current-to-Pressure Converter

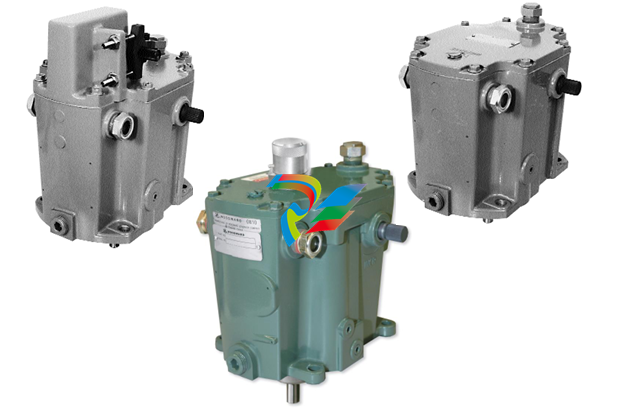

Failsafe Operation: Internal return spring forces Control Port

oil to drain port on loss of power or detected failures

Configuration: Computer based Service Tool (RS-232

communications port)

Physical

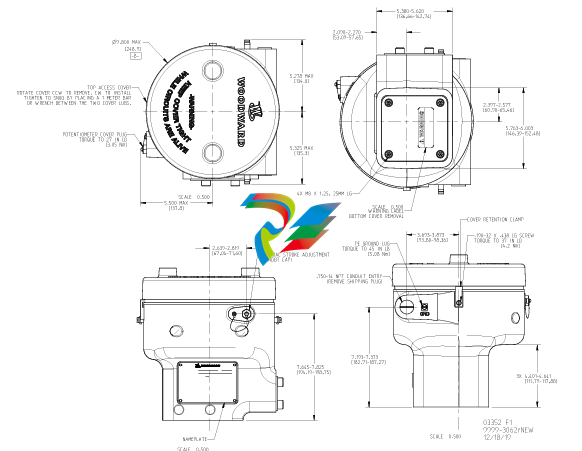

Dimensions: See outline drawings

Height x Width x Depth: Approx. (290 x 270 x 270) mm

Weight: Approximately 25 kg (55 lb) without oil

Fluid Ports: See outline drawings

Mounting: Any attitude, Four M10 threaded holes,

23 mm deep, on the face with the hydraulic ports.

Adequate support must be provided for the unit.

Environmental

Operating Temperature Range: (–40 to +85) °C

Hydraulic Supply Temperature: (15 to 70) °C

Immunity: EN61000-6-2 (2005)

Emissions: EN61000-6-4 (2007)

Shock: US MIL-STD-810C method 516.2. procedure 1 (10 G

Peak, 11 ms duration, saw tooth waveform)

Vibration: US MIL-STD 810F, M514.5A, Cat. 4 (0.015 G²/Hz,

(10 to 500) Hz, 1.04 Grms)

Ingress Protection: IP66 per EN 60529

Electrical

Input Supply: (18 to 32) V (dc) @ 1.5 A steady state, 8 A

peak (100 ms)

Analog Input Signals: Isolated (4 to 20) mA (250 Ω input

impedance)

Analog Output Signal: (4 to 20) mA; maximum external load:

300 Ω, Accuracy = ±1 % of full scale

Discrete Inputs: Optically Isolated (requires 24 V (dc) wetting

voltage)

Discrete Output Rating: 1 A @ 30 V (dc)

Service Tool Port: RS-232 communications via straight

through serial cable

Hydraulic

Fluid Types: Mineral or synthetic based oils may be used.

Contact Woodward for specific oil recommendations.

Maximum Input Supply Pressure: 25 bar / 363 psi

CPC-II Model

Maximum Output

Pressure Range*

Location

Rating

9907-1197

(0 to 25) bar /

(0 to 363) psi

Zone 1 & 2

9907-1198

(0 to 25) bar /

(0 to 363) psi

Zone 2

9907-1199

(0 to 10) bar /

(0 to 145) psi

Zone 1 & 2

9907-1200

(0 to 10) bar /

(0 to 145) psi

Zone 2

9907-1228

(0 to 10) bar /

(0 to 145) psi

Zone 2

9907-1349

Zone 1 & 2

(0 to 10) bar /

(0 to 145) psi

* Note: The recommended maximum output pressure is less than

70 % of the supply for the best dynamic performance.

Recommended Filtration: (24 to 40) μm nominal, β75 or ISO

20/16 Class

Recommended Viscosity 20 to 100 cSt

Specific Gravity: 0.6 to 1.0

Flow Capacity: Depends on viscosity and pressure difference

(see Figure 3)

Return/Drain Pressure: Maximum 2 bar (29 psi)

Regulatory Compliance

(Listings are limited only to those units bearing the

appropriate Marking or Agency Identification)

European Compliance for CE Marking:

EMC Directive: 2014/30/EU

ATEX Directive: 2014/34/EU For Zone 1: SIRA

11ATEX1310X II 2 G, Ex db IIB T4 Gb. For Zone 2: II 3 G Ex

nA IIC T4 Gc

Other European Compliance: (Compliance with the

following European Directives or standards does not qualify

this product for application of the CE Marking)

Machinery Directive: Compliant as a partly completed

machinery per 2006/42/EC

Pressure Equipment Directive: Compliant as “SEP” per

Article 4.3 to 2014/68/EU

Other International Compliance:

EAC Customs Union: Certified to Technical Regulation CU

012/2011 for use in potentially explosive atmospheres as Ex

d IIB T4 Gb X or 2Ex nA IIC T4 Gc X.

EAC Customs Union: Declared to Technical Regulation CU

020/2011 On Electromagnetic Compatibility of Technical

Equipment.

IECEx: Certified for use in explosive atmospheres per IECEx

Certificate IECEx CSA 11.0017X Zone 1: Ex d IIB T4 Gb and

Zone 2: Ex nA IIC T4 Gc

North American Compliance:

CSA: CSA Certified for Class I, Div. 1. Groups C and D and

Class I, Div. 2. Groups A, B, C, and D, T4 at 85°C Ambient.

For use in Canada and the United States

.png)

.png)