Foxboro FBM223 PROFIBUS-DP™ Communication Interface Module

FBM223 PROFIBUS-DP™ Communication Interface Module

The FBM223 PROFIBUS-DP™ Communication Interface Module provides an interface between

PROFIBUS-DP slave devices and the I/A Series® system.

FEATURES

Key features of the FBM223 module are:

Conforms to PROFIBUS-DP Fieldbus

specifications

Provides full support for all device variables and

diagnostic messages

Integrates PROFIBUS slave device data into an

I/A Series control database

The FBM223 and its associated termination

assembly (TA) are suitable for installation in

Class 1. Division 2 and Zone 2 locations.

OVERVIEW

The PROFIBUS-DP Communication Interface Module

(FBM223) provides an interface between

PROFIBUS-DP slave devices — such as motor

drives, I/O modules, and field I/O devices — and the

I/A Series system.

PROFIBUS is a vendor-independent, open fieldbus

standard for a wide range of applications in process

automation and manufacturing. Vendor

independence and openness are guaranteed by the

PROFIBUS Fieldbus standard EN 50170. which

specifies the functional, electrical, and mechanical

characteristics for a serial transmission bus.

Physical PROFIBUS-DP wiring is in accordance with

Electronic Industrial Association (EIA) standard RS

485.

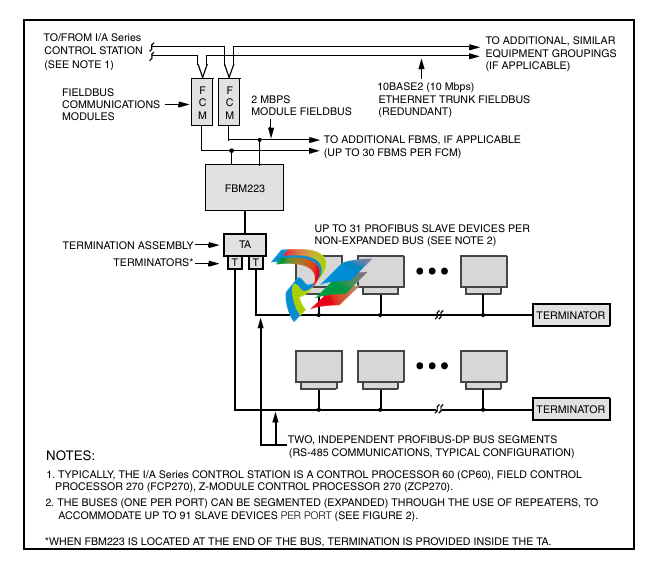

In addition to the general PROFIBUS-DP

configuration shown in Figure 1. several other

configurations are possible, including those using

repeaters and intrinsic safety protective devices.

Figure 2 shows how a bus can be expanded into

multiple segments through the use of repeaters, thus

providing support for a greater number of slave

devices.

FBM223 communicates with the PROFIBUS I/O

devices on a master/slave basis. As master, the

FBM223 initializes each data communication

exchange. The slave devices can only acknowledge

received messages, or send messages to the master

when requested to do so.

PROFIBUS-DP TECHNOLOGY

“DP” (in PROFIBUS-DP) represents the

communication profile that is most often used with

PROFIBUS — decentralized periphery. It is optimized

for speed, efficiency, and low connection cost, and is

designed especially for communication between

automation systems (such as the I/A Series control

system) and distributed field devices.

GSD FILES

A GSD file identifies a PROFIBUS-DP device. It

contains information specific to each device and

specifies parameters such as baud rates, timing

information and supported options such as

diagnostics and data length. A GSD file, provided by

the device manufacturer, is available for each device

type.

The data transmission method used with

PROFIBUS-DP is in accordance with EIA standard

RS-485. a proven serial communication technology

used in universal applications in process control and

manufacturing automation. Applications for RS-485

include all areas in which high transmission speed

and simple, inexpensive installation are required. The

physical communication medium consists of twisted

pair shielded copper cable containing a single

conductor pair. Active bus terminators, required at

either end of the bus or bus segment, typically exist

within the bus connectors or within the devices

themselves.

The I/A Series system uses the information in the

GSD file to set up communication to the slave

device. A configurator, available on the operator

station (UNIX® or Windows® based) allows the

importation of such files for establishing supported

options and for validating the values set by the user

NETWORK EXPANSION

Without the use of repeaters (non-expanded bus

configuration) up to 31 slave stations can exist on a

PROFIBUS-DP bus. Depending on the selected data

transfer rate, cabling distances up to 1200 m

(3960 ft) are possible without the use of repeaters

(see Table 1).

The use of repeaters provides for expansion of the

bus, allowing a greater number of slave devices per

FBM223 port, up to 91.

For a given system, with the use of repeaters the

maximum number of slave devices supported on an

FBM223 port is dependent on the amount of I/O that

is configured per device for access by the FBM223.

FBM CAPACITY

For the complete specification of number of devices

supported versus maximum I/O per device, refer to

the PROFIBUS-DP Communication Interface Module

(FBM223) User’s Guide (B0400FE).

From the I/A Series control station to which the

FBM223 is connected (refer to Figure 1), up to 100

connections per FBM223 port can be made to the

I/O data being accessed (read or written) by the

FBM223 over PROFIBUS.

A connection may be to:

An analog input or output value (integer or

floating point)

A string input or output

A single digital input or output value

Multiple (packed) digital input or output values

(packed in groups of up to 32 digital points per

connection).

Thus an I/A Series control station can access up to

100 analog I/O values, or 3200 digital I/O values, or a

combination of digital, analog, and string I/O, via

each of the two ports of the FBM223. The frequency

of access to FBM223 data by a control station may

be as fas

FIELDBUS COMMUNICATION

TERMINATION ASSEMBLY

The Fieldbus Communications Module (FCM) or the

Field Control Processor (FCP) interfaces to the

redundant 2 Mbps module Fieldbus used by the

FBMs. The FBM223 accepts communication from

either path (A or B) of the 2 Mbps Fieldbus — should

one path fail or be switched at the system level, the

.png)

.png)