Foxboro FBM223 PROFIBUS-DP™ Communication Interface Module

FBM223 PROFIBUS-DP™ Communication Interface Module

The FBM223 PROFIBUS-DP™ Communication Interface Module provides an interface between

PROFIBUS-DP slave devices and the I/A Series® system.

FEATURES

Key features of the FBM223 module are:

Conforms to PROFIBUS-DP Fieldbus

specifications

Provides full support for all device variables and

diagnostic messages

Integrates PROFIBUS slave device data into an

I/A Series control database

The FBM223 and its associated termination

assembly (TA) are suitable for installation in

Class 1. Division 2 and Zone 2 locations.

OVERVIEW

The PROFIBUS-DP Communication Interface Module

(FBM223) provides an interface between

PROFIBUS-DP slave devices — such as motor

drives, I/O modules, and field I/O devices — and the

I/A Series system.

PROFIBUS is a vendor-independent, open fieldbus

standard for a wide range of applications in process

automation and manufacturing. Vendor

independence and openness are guaranteed by the

PROFIBUS Fieldbus standard EN 50170. which

specifies the functional, electrical, and mechanical

characteristics for a serial transmission bus.

Physical PROFIBUS-DP wiring is in accordance with

Electronic Industrial Association (EIA) standard RS

485.

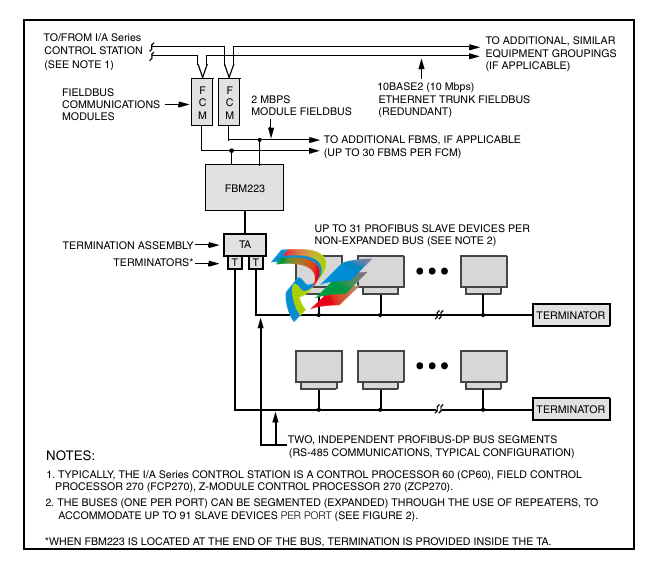

In addition to the general PROFIBUS-DP

configuration shown in Figure 1. several other

configurations are possible, including those using

repeaters and intrinsic safety protective devices.

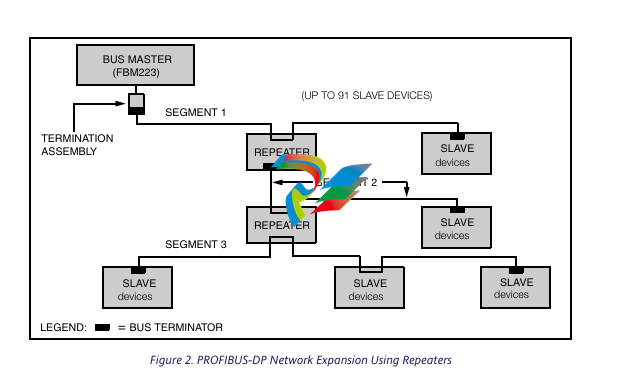

Figure 2 shows how a bus can be expanded into

multiple segments through the use of repeaters, thus

providing support for a greater number of slave

devices.

FBM223 communicates with the PROFIBUS I/O

devices on a master/slave basis. As master, the

FBM223 initializes each data communication

exchange. The slave devices can only acknowledge

received messages, or send messages to the master

when requested to do so.

PROFIBUS-DP TECHNOLOGY

“DP” (in PROFIBUS-DP) represents the

communication profile that is most often used with

PROFIBUS — decentralized periphery. It is optimized

for speed, efficiency, and low connection cost, and is

designed especially for communication between

automation systems (such as the I/A Series control

system) and distributed field devices.

GSD FILES

A GSD file identifies a PROFIBUS-DP device. It

contains information specific to each device and

specifies parameters such as baud rates, timing

information and supported options such as

diagnostics and data length. A GSD file, provided by

the device manufacturer, is available for each device

type.

The data transmission method used with

PROFIBUS-DP is in accordance with EIA standard

RS-485. a proven serial communication technology

used in universal applications in process control and

manufacturing automation. Applications for RS-485

include all areas in which high transmission speed

and simple, inexpensive installation are required. The

physical communication medium consists of twisted

pair shielded copper cable containing a single

conductor pair. Active bus terminators, required at

either end of the bus or bus segment, typically exist

within the bus connectors or within the devices

themselves.

The I/A Series system uses the information in the

GSD file to set up communication to the slave

device. A configurator, available on the operator

station (UNIX® or Windows® based) allows the

importation of such files for establishing supported

options and for validating the values set by the user

NETWORK EXPANSION

Without the use of repeaters (non-expanded bus

configuration) up to 31 slave stations can exist on a

PROFIBUS-DP bus. Depending on the selected data

transfer rate, cabling distances up to 1200 m

(3960 ft) are possible without the use of repeaters

(see Table 1).

The use of repeaters provides for expansion of the

bus, allowing a greater number of slave devices per

FBM223 port, up to 91.

For a given system, with the use of repeaters the

maximum number of slave devices supported on an

FBM223 port is dependent on the amount of I/O that

is configured per device for access by the FBM223.

FBM CAPACITY

For the complete specification of number of devices

supported versus maximum I/O per device, refer to

the PROFIBUS-DP Communication Interface Module

(FBM223) User’s Guide (B0400FE).

From the I/A Series control station to which the

FBM223 is connected (refer to Figure 1), up to 100

connections per FBM223 port can be made to the

I/O data being accessed (read or written) by the

FBM223 over PROFIBUS.

A connection may be to:

An analog input or output value (integer or

floating point)

A string input or output

A single digital input or output value

Multiple (packed) digital input or output values

(packed in groups of up to 32 digital points per

connection).

Thus an I/A Series control station can access up to

100 analog I/O values, or 3200 digital I/O values, or a

combination of digital, analog, and string I/O, via

each of the two ports of the FBM223. The frequency

of access to FBM223 data by a control station may

be as fas

FIELDBUS COMMUNICATION

TERMINATION ASSEMBLY

The Fieldbus Communications Module (FCM) or the

Field Control Processor (FCP) interfaces to the

redundant 2 Mbps module Fieldbus used by the

FBMs. The FBM223 accepts communication from

either path (A or B) of the 2 Mbps Fieldbus — should

one path fail or be switched at the system level, the

module continues communication over the active

path.

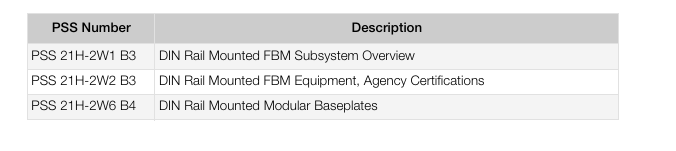

MODULAR BASEPLATE MOUNTING

The module mounts on a Modular Baseplate (see

Figure 3), which accommodates up to four or eight

FBMs. The Modular Baseplate is either DIN rail

mounted or rack mounted, and includes signal

connectors for the FBMs, redundant independent dc

power connections, and I/O cable connections.

Features

Key features include:

Combination foot that supports 32 or 35 mm DIN

rail mounting

Distinct family group color

Three-tier termination

Switch-selectable termination resistors.

Overview

Field I/O signals connect to the FBM subsystem via

DIN rail mounted termination assemblies (TAs).

Each FBM223 PROFIBUS-DP Termination Assembly

and its associated termination cable provide feed

through connection between PROFIBUS-DP

compliant field devices and the FBM223

PROFIBUS-DP Communication Input Interface

Module.

The TA is available in Polypropylene (PVC) material.

The DIN rail mounted TAs connect to the Modular

Baseplate by means of a removable termination

cable. The cable is available in a variety of lengths, up

to 30 meters (98 feet), allowing the TA to be mounted

in either the enclosure or in an adjacent enclosure.

Termination cables are available in the following

materials:

Polyurethane

Hypalon® XLP (fire retardant).

Refer to Table 2 on page 11.

FUNCTIONAL SPECIFICATIONS

PROFIBUS-DP Communications

INTERFACE

2 communication channels provide interface to 2

isolated PROFIBUS-DP buses

BUS CHARACTERISTICS

General

Electronic Industrial Association (EIA) RS

485 communications. The physical

communication medium consists of twisted

pair shielded copper cable containing a

single conductor pair.

Data Transfer Rate (Baud Rate)

Selectable, 9.6 to 12.000 kbit/sec (see

Table 1)

FBM223 CHANNEL ISOLATION

Each communication channel is galvanically isolated

and referenced to earth (ground). The module can

withstand, without damage, a potential of 600 V ac

applied for one minute between either channel and

earth.

CAUTION

This does not imply that the channels are

intended for permanent connection to

voltages of these levels. Exceeding the limits

for input voltages, as stated elsewhere in this

specification, violates electrical safety codes

and may expose users to electric shock.

Maximum Allowable Bus Length

The maximum allowable length of a

PROFIBUS-DP bus segment is a function of

the user selected data transfer rate (see

Table 1)

Maximum Cable Length, FBM223 to TA

30 m (90 ft) which is to be included in the

bus segment length

Maximum Number of Devices (Total) on a

Bus

Per EN 50170. for a non-expanded bus

(repeaters not used), one master and up to

31 slaves are supported. For an expanded

bus, the number of slave devices allowed is

a function of the allowable input/output data

processed per slave device (refer to the

PROFIBUS-DP Communication Interface

Module (FBM223) User’s Guide (B0400FE)).

The maximum number supported per port is

91.

Maximum Number of Devices on a Bus

Segment

Per EN 50170. a bus segment (in an

expanded network) supports up to 32 active

devices. An active device can be a master,

slave, or repeater.

FASTEST ALLOWED ECB BLOCK PERIOD

500 msec

Conformance to PROFIBUS-DP Standards

PROFIBUS-DP bus topologies and communications

are in accordance with specifications presented in the

following standards:

PROFIBUS Fieldbus standard EN 50170

EIA standard RS-485.

FBM223 Power Requirements

INPUT VOLTAGE RANGE (REDUNDANT)

24 V dc +5%, -10%

CONSUMPTION

6 W (maximum)

HEAT DISSIPATION

6 W (maximum)

FUNCTIONAL SPECIFICATIONS (CONTINUED)

Regulatory Compliance

ELECTROMAGNETIC COMPATIBILITY (EMC)

European EMC Directive 89/336/EEC

Meets:EN 50081-2 Emission standard

EN 50082-2 Immunity standard

EN 61326 Annex A (Industrial Levels)

CISPR 11. Industrial Scientific and

Medical (ISM) Radio-frequency

Equipment - Electromagnetic Disturbance

Characteristics - Limits and Methods of

Measurement

Meets: Class A Limits

IEC 61000-4-2 ESD Immunity

Contact 4 kV, air 8 kV

IEC 61000-4-3 Radiated Field Immunity

10 V/m at 80 to 1000 MHz

IEC 61000-4-4 Electrical Fast

Transient/Burst Immunity

2 kV on I/O, dc power and communication

lines

IEC 61000-4-5 Surge Immunity

2kV on ac and dc power lines; 1kV on I/O

and communications lines

IEC 61000-4-6 Immunity to Conducted

Disturbances Induced by Radio

frequency Fields

10 V (rms) at 150 kHz to 80 MHz on I/O, dc

power and communication lines

IEC 61000-4-8 Power Frequency

Magnetic Field Immunity

30 A/m at 50 and 60 Hz

IEC 61000-4-11 Voltage Dips, Short

Interruptions and Voltage Variations

ENVIRONMENTAL SPECIFICATIONS(1)

Operating

TEMPERATURE

FBM223-20 to +70°C (-4 to +158°F)

Termination Assembly-20 to +50°C (-4 t

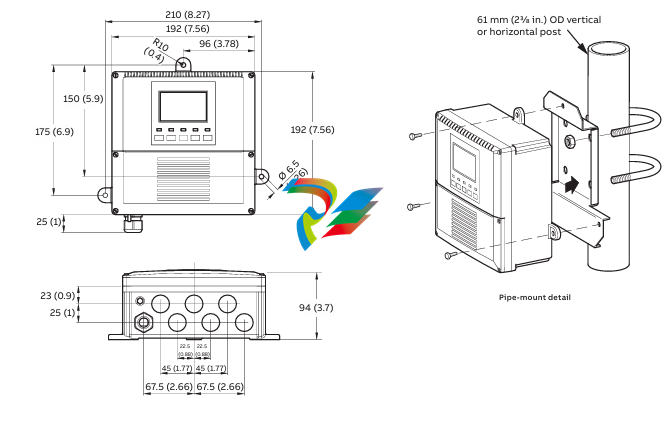

PHYSICAL SPECIFICATIONS

Mounting

MODULE

The FBM223 mounts on a Modular Baseplate.

The Modular Baseplate can be mounted

horizontally or vertically on a DIN rail, or mounted

horizontally in a 19-inch rack using a mounting

kit. Refer to PSS 21H-2W6 B4 for details.

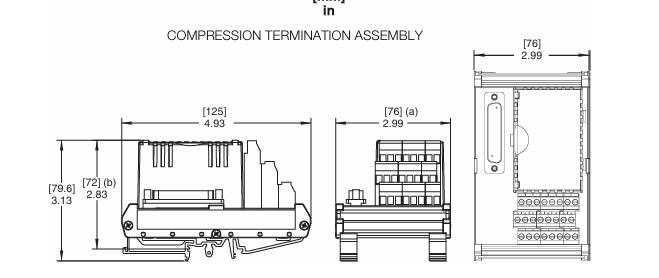

TERMINATION ASSEMBLY

The TA accommodates multiple DIN styles

including 32 mm (1.26) and 35 mm (1.38 in) rails.

Mass

MODULE

284 g (10 oz) approximate (each module)

TA - COMPRESSION SCREW

363 g (0.8 lb) approximate

Dimensions

MODULE

HEIGHT

102 mm (4 in)

114 mm (4.5 in) including mounting lugs

WIDTH

45 mm (1.75 in)

DEPTH

104 mm (4.11 in)

TERMINATION ASSEMBLY

See page 12

Part Numbers

FBM223 MODULE

P0917HD

TA - COMPRESSION SCREW

P0917SY

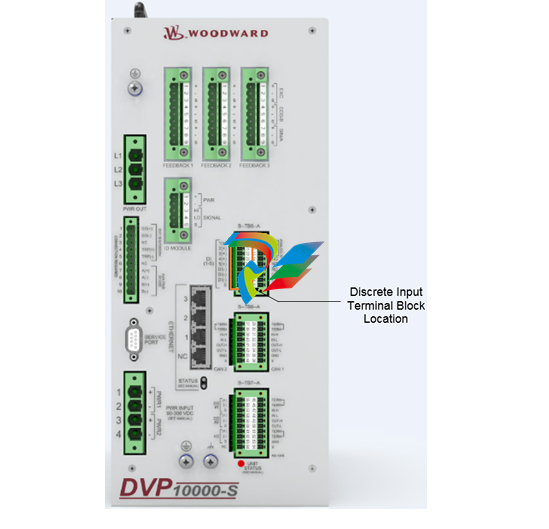

Indicators (mounted on front of each module)

OPERATIONAL STATUS

Red and green light-emitting diodes (LEDs)

CHANNEL COMMUNICATION ACTIVITY

2 amber LEDs, one per port

Termination Cables

CABLE LENGTHS

Up to 30 m (98 ft).

CABLE MATERIALS

Polyurethane or Hypalon XLP

TERMINATION CABLE TYPE

Type 1 - Refer to Table 2 on page 11

CABLE CONNECTION

Termination Assembly

25-pin male D-subminiature

Modular Baseplate

37-pin male D-subminiature

Termination Assembly Construction Material

MATERIAL

Polypropylene (PVC) Material, compression

screw

FAMILY GROUP COLOR

Green - communication

TERMINAL BLOCKS

Inputs and Outputs - 3 tiers, 8 positions

Field Termination Connections

COMPRESSION-TYPE ACCEPTED WIRING SIZES

Solid/Stranded/AWG

0.2 to 4 mm2/0.2 to 2.5 mm2/24 to 12 AWG

Stranded with Ferrules

0.2 to 2.5 mm2 with or without plastic colla

.png)

.png)