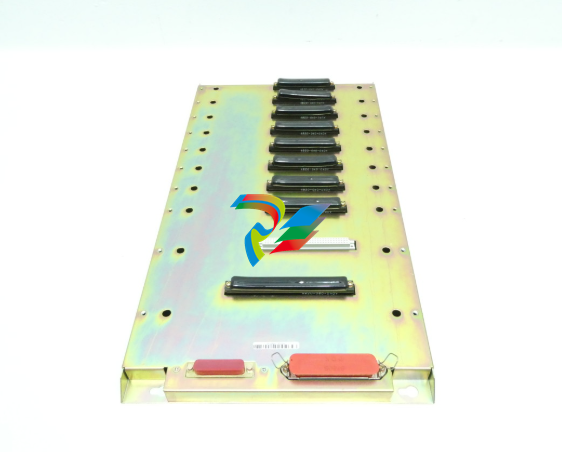

ABB Advant Controller 31 Hardware 90 Series

1.3

General instructions for EMC-compatible installation

Systemdaten und Systemaufbau

Electric and electronical devices have to work correctly on site. This is also valid when electro-magnetic influences affect

them in defined and/or expected strength. The devices themselves must not emit electro-magnetic noises.

Advant Controller components are developed and constructed so that they have a very high noise immunity. When the

wiring and earthing instructions under "System data and system configuration" in volume 2 are met, an error-free opera

tion is given.

However, there are applications where high electro-magnetic noises must be taken into due consideration already during

the planning phase: e.g. when frequency converters, compressors, small-power pumps (high inductance) or medium

voltage switchgear are mounted nearby. An EMC-compatible earthing concept will also guarantee here an error-free

operation.

There are three important principles to be especially considered:

• Keep all connections as short as possible (in particular the earthing conductors)

• Use large conductor cross sections (in particular for the earthing conductors)

• Create good and large-sized contacts (in particular for the earthing conductors)- vibration-resistant connections- clean metallic contact areas (remove paint, clean surfaces)- solid plug and screw-type connections- earth cable shields with clips on a well grounded metallic surface,- do not use sheath wires- do not use toothed lock washers under screwed connection

1.4 Check list for project planning and installation

good contact

This chapter contains a list of reminders to check whether all of the important items have been taken into consideration

during planning and installation

1.4.2 Everything firmly attached

• AC31 module firmly plugged on the plug-in base (all screws fastened)

1.4.3 Everything correctly set

• Operating modes correctly set on the modules (e.g. DIL switch)

• Correct input/output terminals on the modules used (e.g. voltage inputs or outputs on the analog modules

• Adresses correctly set

1.4.4 Laying cables

• Power cables (230/400 V) laid out separately from the control cables (24 V, analog signals), whenever

possible with a distance of 20 cm or more

• Sufficient conductor cross sections

• Sufficient cable insulation / cable shielding

• Supply lines of the power supply connected to the central units with flanged couplers

(e.g. 07 KT 97 with 07 KP 90)-

The supply lines are first connected to the central unit (07 KT 97), and then looped

to the coupler (07 KP 90), see the descriptions of the coupler.

1.4.5 PE connection

• Infeed of earthing potential to the PE bar with large conductor cross section

• Connection of the PE bar to the mounting steel plate

• Connection of the switchgear cabinet components to each other

• Connection of movable switchgear components to PE (doors)

• PE Faston connection of central units and couplers (see module descriptions)

• CS31 bus shield to PE

• Connections between analog cable shields and PE

• Reference potentials of the output voltages of the power supply units are interconnected and grounded

1.4.6 CS31 System bus (see also volume 2. system data, system design)

• Bus line is looped through from module to module

• no spur lines

• Bus length (max. 500 m, measure cable length before installation, when necessary)

• Bus terminating resistors (see system data)

• Bus terminals (BUS1 to BUS1. BUS2 to BUS2)

.png)