Woodward 85018V1 Turbine Control Parameters

Turbine Control Parameters

The 505E interfaces with two control valves (HP & LP) to control two parameters

and limit an additional parameter, if desired. These two controlled parameters are

typically speed (or load) and extraction/admission pressure (or flow), however,

the 505E could be utilized to control or limit: turbine inlet pressure or flow,

exhaust (back) pressure or flow, first stage pressure, generator power output,

plant import and/or export levels, compressor inlet or discharge pressure or flow,

unit/plant frequency, process temperature, or any other turbine related process

parameter. Refer to Volume 2 for details on applications.

Communications

The 505E can communicate directly with plant Distributed Control Systems

and/or CRT based operator control panels, through two Modbus® *

communication ports. These ports support RS-232. RS-422. or RS-485

communications using ASCII or RTU MODBUS transmission protocols.

Communications between the 505E and a plant DCS can also be performed

through hardwired connections. Since all 505E PID setpoints can be controlled

through analog input signals, interface resolution and control is not sacrificed.

*—Modbus is a trademark of Schneider Automation Inc.

Additional Features

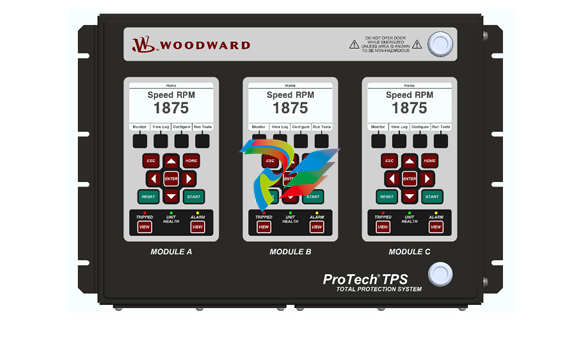

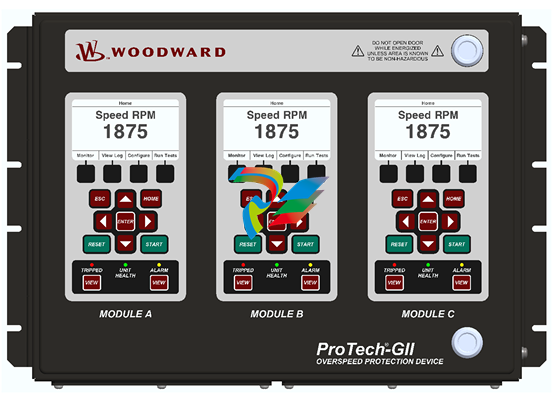

The 505E also provides the following features: First-Out Trip Indication (5 total

trip inputs), Critical Speed Avoidance (2 speed bands), Auto Start Sequence (hot

& cold starts), Dual Speed/Load Dynamics, Zero Speed Detection, Peak Speed

Indication for Overspeed trip, and Isochronous Loadsharing between units.

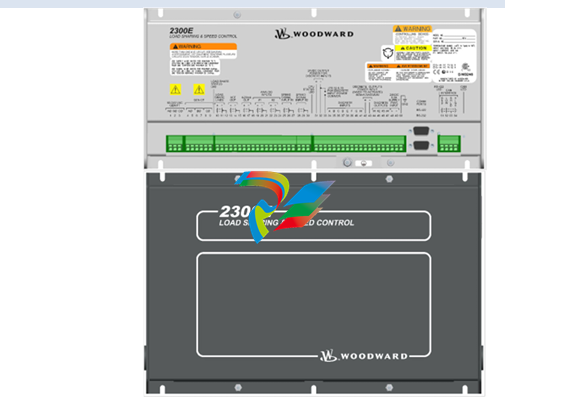

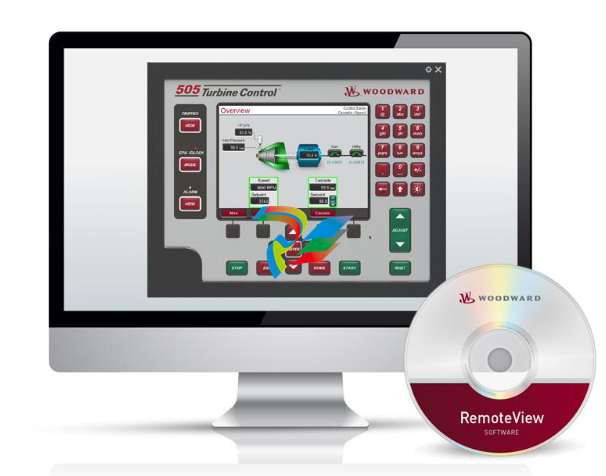

Using the 505E

The 505E control has two normal operating modes, the Program Mode and the

Run Mode. The Program Mode is used to select the options needed to configure

the control to your specific turbine application. Once the control has been

configured, the Program Mode is typically never again used, unless turbine

options or operation changes. Once configured, the Run Mode is used to operate

the turbine from start-up through shutdown. In Addition to the Program and Run

modes, there is a Service Mode which can be used to enhance system operation

while the unit is running. Refer to Volume 2 for information on the Service Mode.

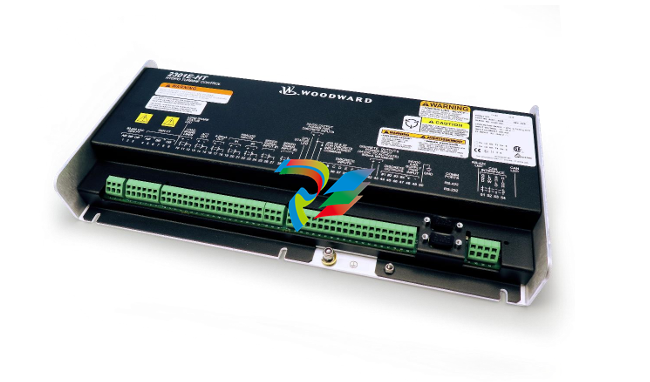

505E Inputs and Outputs

Control Inputs

Two speed inputs which are jumper configurable for MPU (magnetic pickup units)

inputs or proximity probes.

Six analog inputs are available. One is dedicated as the extraction/admission

input. The remaining five are configurable. The sixth analog input has isolation

circuitry and should be used for a self-powered signal that is not isolated.

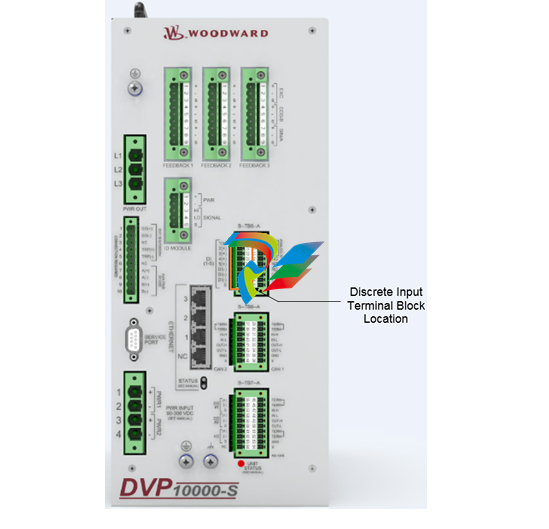

Sixteen contact inputs are available. Four are dedicated for shutdown, reset,

raise speed setpoint, and lower speed setpoint. Another two contact inputs must

be dedicated for generator breaker and utility tie breaker if the control is used in a

generator application. Ten additional contact inputs can be configured. If the unit

is not used in a generator application, then twelve additional contact inputs can

be configured.

Four function keys on the front panel of the control. F1 and F2 are dedicated to

alarm and overspeed test, respectively. F3 and F4 can be used to enable or

disable various functions of the control.

Control Outputs

Two actuator outputs with linearization curves for the HP and the LP valve

outputs.

Six 4–20 mA outputs, for meters or other readouts.

Eight Form-C relay contact outputs, six that are configurable. The two dedicated

relay outputs are for shutdown and alarm indication.

Control Communications

Two Modbus ports, to be used as control interfaces. The protocol can be either

ASCII or RTU and the communications can be RS-232. RS-422. or RS-485.

One computer (PC) port to be used for program configuration storage.

An overview of the 505E functions is shown in Figure 1-1. Use this block diagram

to match the control features to the site-specific application required.

The 505E Digital Governor is designed to control extraction, extraction/

admission, or admission steam turbines. The difference between these turbines

is the capability of the turbine to allow low pressure steam, which is at a lower

pressure than the inlet, to enter and/or exit the turbine. An extraction turbine

allows the lower pressure (extraction) steam to exit the turbine only and will have

a non-return valve in the extraction header/line to prevent steam from entering

the turbine. An admission turbine (also called induction) will allow excess header

steam to enter the turbine through the low pressure inlet. An extraction/admission

turbine will allow low pressure header steam to enter or exit the turbine

depending on system pressures. A turbine with admission capability will have a

stop valve or trip-and-throttle valve in the low pressure line to prevent steam from

entering the turbine when the unit is tripped. The type of turbine used will depend

on the system requirements and must be designed by the turbine manufacturer

to perform the functions required.

The 505E has two independent control channels available, the speed/load and

auxiliary controllers. The outputs of these two controllers are low-signal-selected

(LSS) to provide to speed/load demand signal to the ratio/limiter. In addition to

.png)

.png)