Woodward 85018V1 Turbine Control Parameters

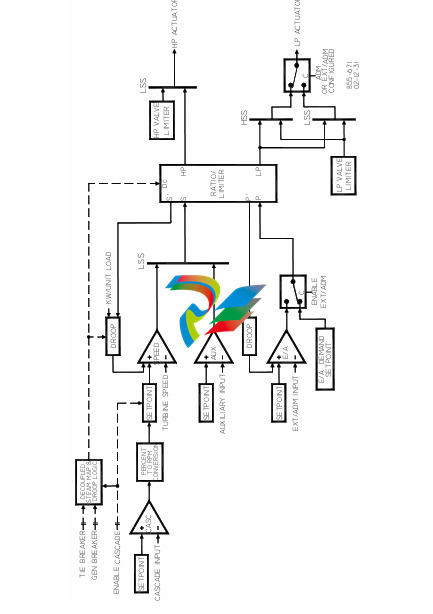

these channels, the speed/ load controller can be manipulated by another

controller, the cascade controller. The cascade controller is ‘cascaded’ into the

speed controller, whereby the speed controller setpoint is changed directly by the

cascade controller output. The auxiliary controller can act as either a control

channel or as a limiting channel. All three of these PID controllers have the

option of utilizing an analog input signal to remotely position their setpoints.

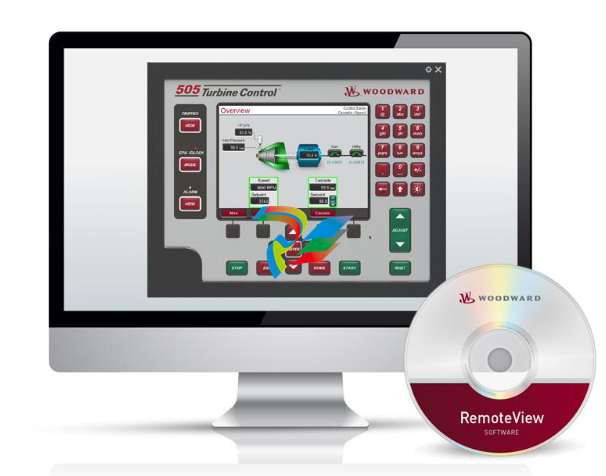

Additional features of the 505E include frequency control, isochronous

loadsharing, critical speed avoidance, idle/rated control, and an automatic start

sequence. There are two serial communications ports which can be used to

monitor and control the turbine using Modbus protocol.

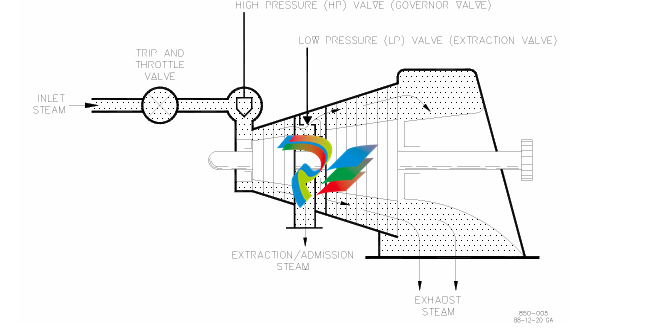

Extraction Turbines

The 505E control can be configured to operate single automatic extraction

turbines by controlling the interaction of the governor (HP or high pressure) valve

and the extraction (LP or low pressure) valve. (The 505E can also operate the

governor valve and the first extraction valve of multiple extraction turbines).

Single automatic extraction turbines have a high pressure stage and a low

pressure stage, each controlled by a valve. Steam enters the turbine through the

HP valve (see Figure 1-2). At the downstream end of the HP turbine stage and

before the LP valve, steam can be extracted. The LP valve controls the entry of

steam into the LP turbine stage, and the diverting of steam through the extraction

line. As the LP valve is opened, more steam enters the LP stage and less is

extracted.

In most cases, the operator of an extraction turbine needs to maintain both

turbine speed/ load and extraction pressure/flow at constant levels. Changing the

position of either the HP valve or the LP valve affects both turbine speed/load

and extraction. If either the load on the turbine or the extraction demand

changes, both the

Admission Turbines

The 505E control can be configured to operate single automatic admission

turbines by controlling the interaction of the governor (HP or high pressure) valve

and the extraction (LP or low pressure) valve.

Single automatic admission turbines have a high pressure stage and a low

pressure stage, each controlled by a valve. Steam enters the turbine through the

HP valve (see Figure 1-3) and at the downstream end of the HP turbine stage,

before the LP valve. The LP valve controls the entry of steam into the LP turbine

stage and through the admission line. As the LP valve is opened, more steam

enters the LP stage.

In most cases, the operator of an admission turbine needs to maintain both

turbine speed/ load and admission pressure/flow at constant levels. Changing the

position of either the HP valve or the LP valve affects both turbine speed/load

and admission. If either the load on the turbine or the admission demand

changes, both the HP valve position and the LP valve position must be changed

to maintain speed/load and admission.

The movement of both valves is automatically calculated by the 505E’s ratioing

logic based on the turbine performance parameters to minimize valve/process

interaction.

Extraction and Admission Turbines

The 505E control can be configured to operate single automatic extraction and

admission turbines by controlling the interaction of the governor (HP or high

pressure) valve and the extraction (LP or low pressure) valve.

Single automatic extraction and admission turbines have a high pressure stage

and a low pressure stage, each controlled by a valve. Steam enters the turbine

through the HP valve (see Figure 1-2). At the downstream end of the HP turbine

stage and before the LP valve, steam can either be extracted or admitted

(inducted) into the LP turbine stage. The LP valve controls the entry of steam into

the LP turbine stage. As the LP valve is opened, more steam enters the LP stage

and less is extracted.

In most cases, the operator of an extraction turbine needs to maintain both

turbine speed/ load and extraction or admission pressure/flow at constant levels.

Changing the position of either the HP valve or the LP valve affects both turbine

speed/load and extraction or admission. If either the load on the turbine or the

extraction / admission demand changes, both the HP valve position and the LP

valve position must be changed to maintain speed/ load and extraction/

admission. The movement of both valves is automatically calculated by the

505E’s ratioing logic based on the turbine performance parameters to minimize

valve/process interaction.

Speed Control

The speed control receives a turbine speed signal from one or two magnetic

pickups or proximity probes. The speed PID (proportional, integral, derivative)

control amplifier then compares this signal to the speed setpoint to generate an

output signal to the ratio/ limiter (through a low signal select bus).

.png)

.png)