ABB UCU-22, UCU-23 andUCU-24control units

ABBINDUSTRIALDRIVES UCU-22, UCU-23 andUCU-24control units

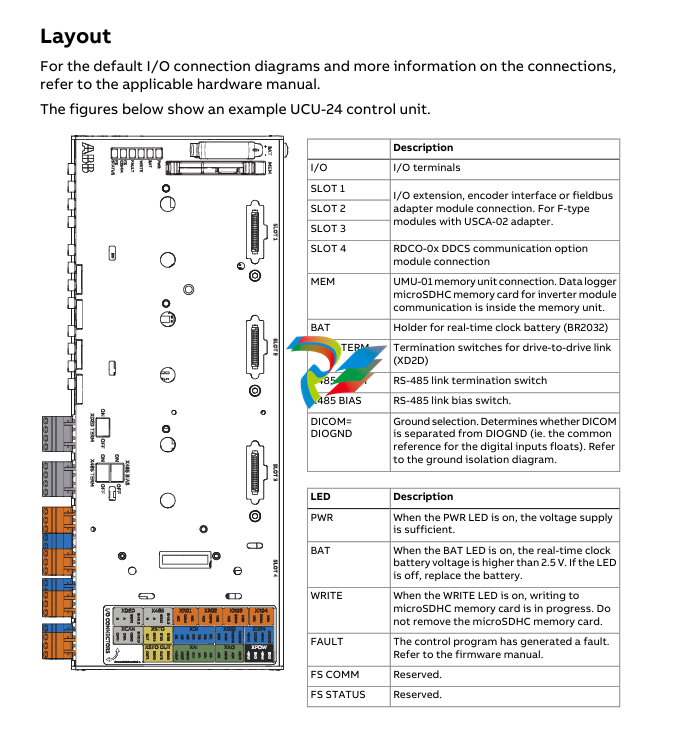

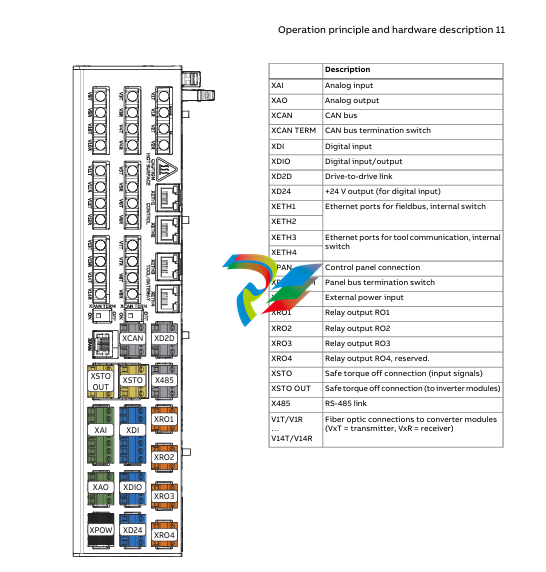

Operation principle and hardware

description

Contents of this chapter

This chapter gives information about the hardware of the control units.

Hardware description

The control unit is an interface for external converter control signals, and it controls

converter modules via fiber optic links. The control unit contains a control board and

connector boards. The control unit contains integrated branching unit functionality

for collecting and storing real-time data from the converter modules to help fault

tracing and analysis. The data is stored on a memory card which can be analyzed by

ABBservice personnel.

The control unit requires an external 24 V DC power source. It has three option slots

for I/O extensions, encoders and fieldbus adapters and functional safety modules,

and aremovable memoryunit. If it is necessary to replace the control unit, you can

keep the parameter settings by moving the memory unit from the defective control

unit tothenewone. ThecontrolunithasoneoptionslotforconnectingaRDCODDCS

communication option module. The control unit also has a connection for a control

panel.

Thedrive-to-drive link (XD2D) is a daisy-chained RS-485 transmission line that allows

basic master/follower communication with one master and multiple followers. The

X485 connection provides a connection for the optional CIO-01 I/O module.

The control unit has two Ethernet ports for control network and two Ethernet ports

fortool/gatewaynetwork. Environmentalsensorsonthecontrolunitmeasurehumidity

and temperature

Contents of this chapter

This chapter gives information on the mechanical installation of the control unit and

the contents of the delivery.

Examining the delivery

Makesurethat these items are included:

• controlunitwiththeI/Oconnector plugs

• memoryunit(UMU-01)

• microSDHCflashmemorycard(insertedinitsslot inside the memory unit)

• optionslotadapters(USCA-02)

• real-timeclock battery (BR2032).

Makesurethat there are no signs of damagetotheitems.

■ Identifying different control unit types

Before you install the control unit, make sure that it has the correct control program.

The control program is shown on the label attached to the memory unit.

Makesurethat the control unit is correct for your equipment configuration

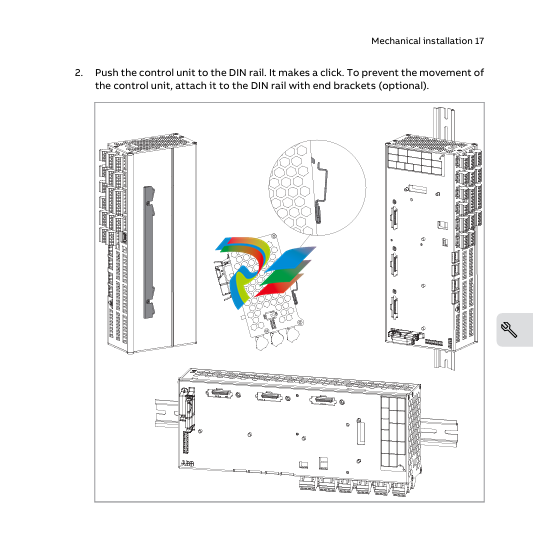

Installing the control unit onto a DIN rail

NOTICE Donotinstallthecontrol unit adjacent to electromagnetic disturbance

sources (for example, relays, contactors, brake choppers, and power cabling). The

minimumrecommendeddistancetosuchcomponentsis200mm(7.9in).ABB

recommendsthatyouinstall metallic screening between the control unit and the

source of disturbance. This can reduce the required distance.

NOTICE Makesurethataircanpassfreelythroughtheventilationholesinthecontrol

unithousing.Donotinstallthecontrolunitdirectlyaboveheat-generatingequipment.

If you do not obeythese instructions, the control unit can become too hot.

Youcaninstallthecontrolunithorizontallyorverticallyontoastandard35×7.5/15mm

DIN rail. If the control unit is installed horizontally, make sure that the connectors

point down. If the control unit is installed vertically, the connectors can point to the

left or right.

Leave sufficient free space around the control unit for:

• cabling

• cooling

• environmentalsensors

• replacingthememoryunitandreal-time clock battery.

The control unit is grounded through the DIN rail and the grounding screw.

1.

Attach thegroundingscrew(M4×6orM4×8)andwiretothecontrolunit.Ground

the control unit to the cabinet frame with the grounding wire. The minimum

cross-sectional area of the ground conductor is 4 mm2 (12 AWG)

Additional information on the connections

■ Powersupplyforthecontrol unit (XPOW)

Refer to the control unit connector data for the current and voltage ratings of the

power supply.

Connect an additional external power supply to the free +24 V and GND terminals of

the XPOWterminal block if:

• thecontrolunitmustbekeptoperationalduringinputpowerbreaks,forexample,

because of continuous fieldbus communication

• immediaterestartisnecessary after a power break (that is, no control unit

power-up delay is permitted).

■ Digital interlock (DIIL)

Digital interlock input (DIIL) terminal is originally intended for interlock signals that

stop the drive/unit when necessary. In the ACS880 primary control program, DIIL

terminal is the source for the run enable signal by default. The inverter unit or drive

cannot start, or it stops when there is no DIIL signal. In other control programs (and

units), the default use of the DIIL terminal varies. Refer to firmware manual for more

information.

Note: This input is not SIL or PL classified.

■ Control panel connection (XPAN)

The XPANconnectorcanbeusedtoconnectanassistant control panel or FDPI-02

diagnostics andpanelinterfaceunittothecontrolunit.WithFDPI-02,itispossibleto

.png)

.png)

.png)