FOXBORO FBM208/b, Redundant with Readback, 0 to 20 mA I/O Module

FOXBORO FBM208/b, Redundant with Readback, 0 to 20 mA I/O Module

Overview

Single input/single output control schemes with high availability requirements can take

advantage of the FBM208 arranged as a redundant pair. A readback feature is

provided that detects failures of the output channel. In a repair situation, when a single

module is replaced, the inputs and outputs are maintained by the redundant module.

HART

signals are electrically compatible with the 4-20 mA signals, permitting the

plant to upgrade field devices without the need to change the control system. The

FBM208b provides the same functionality and is used to upgrade from the older

FBM05.

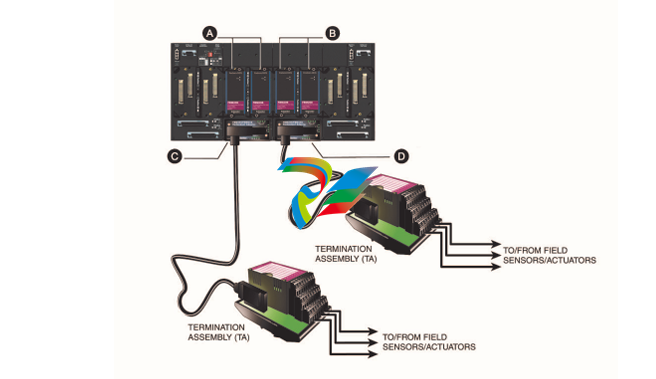

Aredundant pair of the modules combine to provide redundancy at the Fieldbus

Module (FBM) level, with field I/O wired to one common termination assembly (TA)

(see Figure 1. page 4). Each module independently attempts to hold the output(s) at

its specified output value(s), and each independently reports its observed value of the

inputs.

Aredundant analog iput and redundant analog output block in the Foxboro

DCS

Control Software validates each input and output in conjunction with information to/

from the module.

The FBM208is electrically compatible with standard HARTsignals.

• Four0to20mADCanaloginputchannels

• Four0to20mADCanalogoutputchannels with readback

• ComparesFBM’soutput value with the current readback value. If the readback

value differs from the desired output by more than ± 2%, the FBM marks its

output channel BAD.

• Monitors FBM’s internal channel current loop power and marks the channel BAD

if power is less than 16 VDC

• Marking achannel Bad causes the corresponding channel in the redundant

module to continue to drive the outputs

• Redundantmodules increase reliability

• Termination Assemblies (TAs) for locally or remotely connecting field wiring to the

FBM208

The FBMcomparesits output value with the current readback value. If the readback

value differs from the desired output by more than ±2%, the FBM marks its output

channel BAD. In addition, if the output value is greater than the desired output by

more than +2%, the power to that channel is shut off to help prevent the bad channel

from interfering with the control of that channel by the redundant partner FBM. The

power to a detected failed channel remains off until the FBM is replaced or rebooted

by the user.

Whenthe FBM’soutput channel is marked BAD, the CP presents that information to

the Foxboro DCS for display as a System Management alarm message and as a

control block alarm.

Redundant Analog Inputs

Each input channel accepts an analog sensor input such as a 4 to 20 mA transmitter

or a self-powered 4 to 20 mA source.

Transmitter power from each module is diode OR’d together in the redundant adapter

to help assure redundant power.

Aredundant analog input function block, AINR, is used for each redundant pair of

inputs. The AINR block handles input reads and initialization logic for the redundant

channels. On each execution cycle of the AINR block, identical reads are sent to both

modules, fully exercising the fieldbus and the logic circuitry of each module.

Input channel options include a configurable choice of integration time on a per

module basis. Input channel availability is enhanced by redundantly powering the

input current loop from per channel power supplies in each module of the pair.

Redundant Analog Outputs

Each output channel drives an external load and produces a 0 to 20 mA output.

Aredundant analog output block, AOUTR, is used for each redundant pair of outputs.

The AOUTRblock handles output writes and initialization logic for the redundant

channels. On each execution cycle of the AOUTR block, identical output writes are

sent to both modules, fully exercising the fieldbus and the logic circuitry of each

module. When a failure is detected in one of the modules, its output is driven to 0 mA

and the corresponding channel in the good module automatically continues supplying

the proper current to the output current loop.

Configurable options in the modules for output failsafe and fallback options are always

set to their default values (0 mA). This removes one of the pair of redundant output

channels from service for detectable problems such as a module not properly

receiving output writes or not passing diagnostic tests on FBM microprocessor writes

to output registers. Using the default failsafe/fallback options of 0 mA output also

minimizes the possibility of a “fail high” result.

High Accuracy

High Reliability

For high accuracy, the module incorporates sigma-delta converters for each channel.

This provides new analog input readings every 25 ms and a configurable integration

period to remove any process noise and power line frequencies. Each time period, the

FBMconverts each analog input to a digital value, averages these values over the

time period and provides the averaged value to the controller.

The redundancy of the module pair, coupled with the high coverage of detected faults,

provides a very high subsystem availability time.

The microprocessor of each module executes the analog I/O application program,

plus diagnostic routines that validate the health of the FBM.

Either module may be replaced without upsetting field input or output signals to the

.png)