FOXBORO FBM201e Analog Input (0 to 20 mA) Interface Modules

FOXBORO FBM201e Analog Input (0 to 20 mA) Interface Modules

The FBM201e Analog Input Interface Module provides eight dc current input channels.

FEATURES

Key features of the FBM201e module are:

Eight 0 to 20 mA dc channels for input of analog

sensor signals

Each analog input channel is galvanically isolated

from other channels and ground

Compact, rugged design suitable for enclosure in

Class G3 (harsh) environments

Execution of an analog input application program

that provides conversion time and configurable

options for integration time and Rate of Change

Limits

High accuracy achieved by sigma-delta data

conversions for each channel

Termination Assemblies (TAs) for locally or

remotely connecting field wiring to the FBM201e

Termination Assemblies for per channel internally

and/or externally loop powered transmitters.

OVERVIEW

Each FBM201e Analog Input Interface Module

contains eight analog input channels, each channel

accepting a 2-wire, dc input from an analog sensor

such as a 4 to 20 mA transmitter

The modules perform the signal conversion required

to interface the electrical input signals from the field

sensors to the optionally redundant fieldbus.

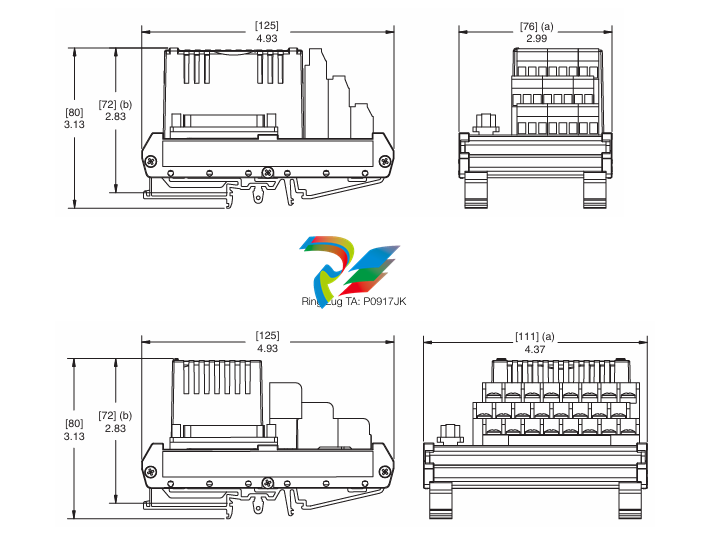

COMPACT DESIGN

The FBM201e module has a compact design, with a

rugged extruded aluminum exterior for physical

protection of the circuits. Enclosures specially

designed for mounting the FBMs provide various

levels of environmental protection, up to harsh

environments per ISA Standard S71.04.

HIGH ACCURACY

For high accuracy, the module incorporates sigma

delta data conversion on a per-channel basis, which

can provide a new analog input reading every 25 ms,

and a configurable integration period to remove any

process noise and power-line frequency noise.

Each time period, the FBM converts each analog

input to a digital value, averages these values over

the time period, and provides the averaged value to

the controller.

EASY REMOVAL/REPLACEMENT

The module can be removed/replaced without

removing field device termination cabling, power or

communications cabling.

VISUAL INDICATORS

Light-emitting diodes (LEDs) incorporated into the

front of the modules provide visual status indications

of Fieldbus Module (FBM) functions.

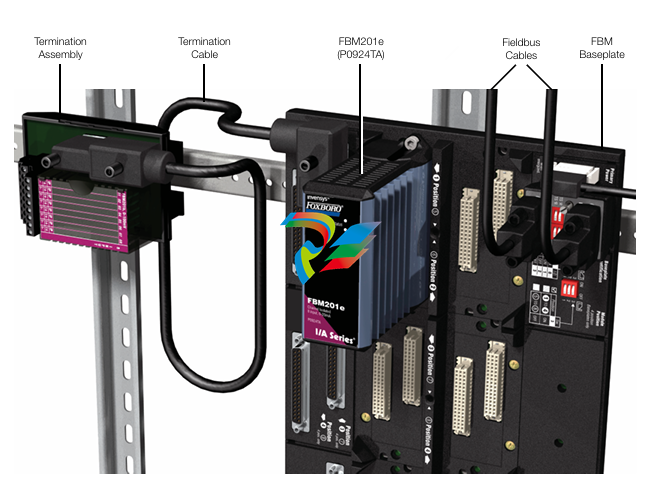

MODULAR BASEPLATE MOUNTING

The module mounts on a modular baseplate (see

Figure 1) which accommodates up to four or eight

FBMs. The modular baseplate is either DIN rail

mounted or rack mounted, and includes signal

connectors for redundant fieldbus, redundant

independent dc power, and termination cables.

FIELDBUS COMMUNICATION

A Fieldbus Communication Module or a Control

Processor interfaces the redundant 2 Mbps module

Fieldbus used by the FBMs. The FBM201e module

accepts communication from either path (A or B) of

the redundant 2 Mbps fieldbus – should one path fail

or be disabled at the system level, the module

continues communication over the active path.

TERMINATION ASSEMBLIES

Field I/O signals connect to the FBM subsystem via

DIN rail mounted TAs (see Figure 1). The TAs used

with the FBM201e module are described in

“TERMINATION ASSEMBLIES AND CABLES” on

page 7

FUNCTIONAL SPECIFICATIONS

Process I/O Communications

Communicates with its associated FCM or FCP via

the redundant 2 Mbps module Fieldbus.

Input Channels

8 isolated and independent channels

Input Range (each channel)

0 to 20 mA dc

Input Channels (8)

ANALOG ACCURACY (INCLUDES LINEARITY)

±0.02% of span

Accuracy temperature coefficient: ±50 ppm/ºC

FIELD DEVICE CABLING DISTANCE

Maximum distance of the field device from the

FBM is a function of compliance voltage @20 mA

(21.4 V dc), wire resistance, and voltage drop at

the field device.

Input Channel Isolation

Each channel is galvanically isolated from all other

channels and earth (ground). The module/TA

withstands, without damage, a potential of 600 V ac

applied for one minute between any channel and

ground, or between a given channel and any other

channel.

WARNING

This does not imply that these channels are

intended for permanent connection to

voltages of these levels. Exceeding the limits

for input voltages, as stated elsewhere in this

specification, violates electrical safety codes

and may expose users to electric shock.

Power Requirements

INPUT VOLTAGE RANGE (REDUNDANT)

INPUT CHANNEL IMPEDANCE

61.5 Ω nominal

INPUT SIGNAL A/D CONVERSION

Each channel performs A/D signal conversion

using an independent Sigma-Delta converter.

INTEGRATION PERIOD

Software configurable.

COMMON MODE REJECTION

>100 db at 50 or 60 Hz

NORMAL MODE REJECTION

>95 db at 50 or 60 Hz

LOOP SUPPLY

24 V dc ±2.5%

OUTPUT IMPEDANCE

68 Ω

LOOP POWER SUPPLY PROTECTION

Each channel is channel-to-channel galvanically

isolated, current limited, and voltage regulated.

All analog inputs are limited by their design to less

than 30 mA. If the current limit circuit shorted out,

the current is limited to about 100mA.

24 V dc +5%, -10%

CONSUMPTION

7 W (maximum)

HEAT DISSIPATION

3 W (maximum)

Calibration Requirements

Calibration of the module and termination assembly is

not required

FUNCTIONAL SPECIFICATIONS (CONTINUED)

Regulatory Compliance

ELECTROMAGNETIC COMPATIBILITY (EMC)

European EMC Directive 89/336/EEC

Meets: EN 50081-2 Emission standard

EN 50082-2 Immunity standard

EN 61326 Annex A (Industrial

Levels)

CISPR 11. Industrial Scientific and Medical

.png)