Woodward Product Change Notification 06912

Product Change Notification 06912

(Revision B, 6/2013)

Overview

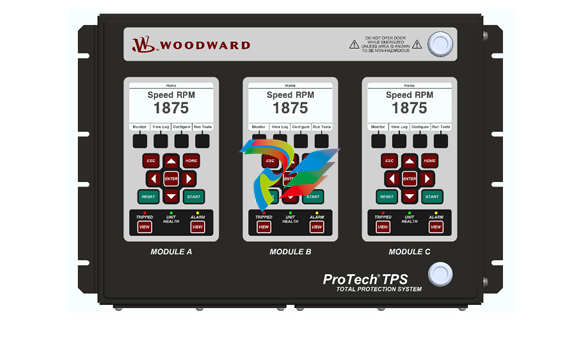

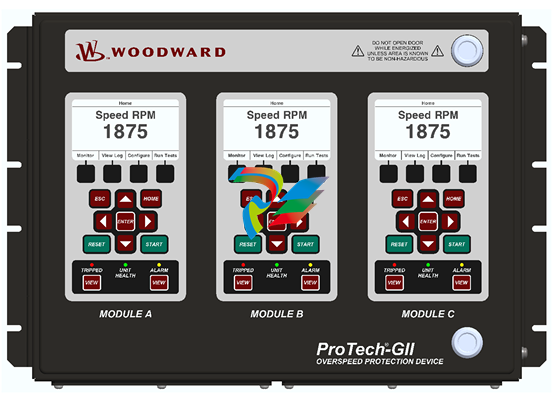

Woodward is releasing new ProTech®-GII models on 17 May 2013. These new models include the same

basic functionality as current ProTech-GII models, and include the improvements listed below as well as

new capabilities.

In an effort to minimize the risk of future application issues, and since the new/improved models are direct

drop-in replacements for the existing models, Woodward plans to change all existing models to “non

preferred” on 15 July 2013. and all new models to “preferred”. Refer to Table 1 below for specific part

number information. Depending on the migration rate to the new ProTech-GII models, Woodward plans to

inactivate all old non-preferred models within the next 12 to 18 months. Please inform affected purchasing

teams and customers accordingly.

Product Change / Improvement

The below listed “preferred” models include the following changes, improvements, and additions:

1.

All module speed inputs are shared with all other modules (A, B, C).

All module trip and alarm latch output statuses are shared with all other modules (A, B, C).

All module “Start”, “Reset”, and “Speed Failed Override” commands are shared with all other modules

(A, B, C).

Added Speed Redundancy Manager Block:

With all input sensors/channels healthy, each module to be configured to select the desired

speed (median, HSS, or LSS) to use for its alarm and trip logic.

Upon one failed input sensor/channel, each module to be configured to select the desired speed

(HSS or LSS) to use for its alarm and trip logic.

Upon two failed input sensors/channels, each module to be configured to select the desired

action (issue a trip command or use healthy speed input sensor/channel for its alarm and trip

logic).

Allows users to configure the use of 3 or 2 or 1 speed input sensors/channels.

Includes “Speed Difference Detection” alarm function. Note that this feature can be easily used to

assist in detecting a failed active or passive speed sensor.

Note: New speed redundancy manager logic allows users to configure the voting logic to meet Shell’s

2-out-of-2 voting requirement when only two inputs are available/healthy.

Added Acceleration Redundancy Manager Block:

With all input sensors/channels healthy, each module to be configured to select the desired

acceleration rate (median, HSS, or LSS) to use for its alarm and trip logic.

Upon one failed input sensor/channel, each module to be configured to select the desired

acceleration rate (HSS or LSS) to use for its alarm and trip logic.

Allows users to configure the use of 3 or 2 or 1 speed input sensors/channels.

Added Boolean Input Manager Functions:

Each of the ProTech-GII’s contact/Boolean inputs (Start, Reset, and Speed Failed Override) can

be configured to use the respective contact/Boolean input command from any or all of the other

modules.

When configured, any or all of the configured discrete input commands are “ORed” together.

Example—If module A’s “Reset” function is configured to use module A’s and module B’s “Reset”

contact input commands, then a “Reset” command received from the A or B module will activate

module A’s Reset logic.

Boolean Input Manager functions can only be configured from the ProTech-GII’s PCT software

service tool.

The ORed Boolean Input Manager functions, if configured, only manage the action of a module’s

contact inputs commands. The Reset and Start keys on the module’s front panel function

independently of the Boolean Input Manager and only affect the respective module’s action.

Added configurable “Failed Power Supply #1” and “Failed Power Supply #2” Alarm Override functions.

Allows users to configure the module to accept only one power supply, thus removing a nuisance

Failed Power Supply Alarm indication.

Changed Speed Fail Alarm function to be overridden during the turbine start state/mode.

This removes a nuisance alarm during a turbine start-up.

Changed Speed Lost Alarm/Trip threshold level from 100 Hz to 200 Hz to reduce/remove nuisance

alarms/trips when applied with speed gears that have less than 60 teeth and turbines that can slow roll

at low speeds.

10. Changed the name of “Periodic Overspeed Test” to “Auto Sequence Test”.

11. Added an option to start the Auto Sequence Test Routine from the Auto Sequence Test screen. This

allows a user to instantly start the Auto Sequence Test function when desired.

12. Added an option to disable Auto Sequence Test routine from the Auto Sequence Test screen. This

allows a user to disable the Auto Sequence Test function from being performed. Since the Auto

Sequence Test routine can be configured to be performed on a periodic basis, the “Disable” function

allows users to temporarily disable the periodic test routine from being performed when desired.

13. Added an Auto Simulated Speed Test Failed Alarm to indicate the failure of the Auto Simulated Test

routine.

14. Added a configurable permissive for any Test routine, which will not allow the Test function to be

started if any other module has an “Alarm” condition active. Users now have the following configurable

Test “permissive” options: None, Module Not Tripped, or Module Not In Alarm. If configured, the test

.png)

.png)