Honeywell 5704 Control System: Technical Summary

Honeywell 5704 Control System: Technical Summary

Introduction & System Concept

This document provides a technical summary of the Honeywell 5704 Control System, a component of the broader System 57 family. The 5704 system is a microprocessor-based, modular control system designed to monitor industrial gas detectors. It provides display, alarm, and control functionalities for up to 64 channels in a standard 19-inch rack. Its primary purpose is to process signals from field-mounted sensors and initiate alarms or control actions based on pre-configured setpoints.

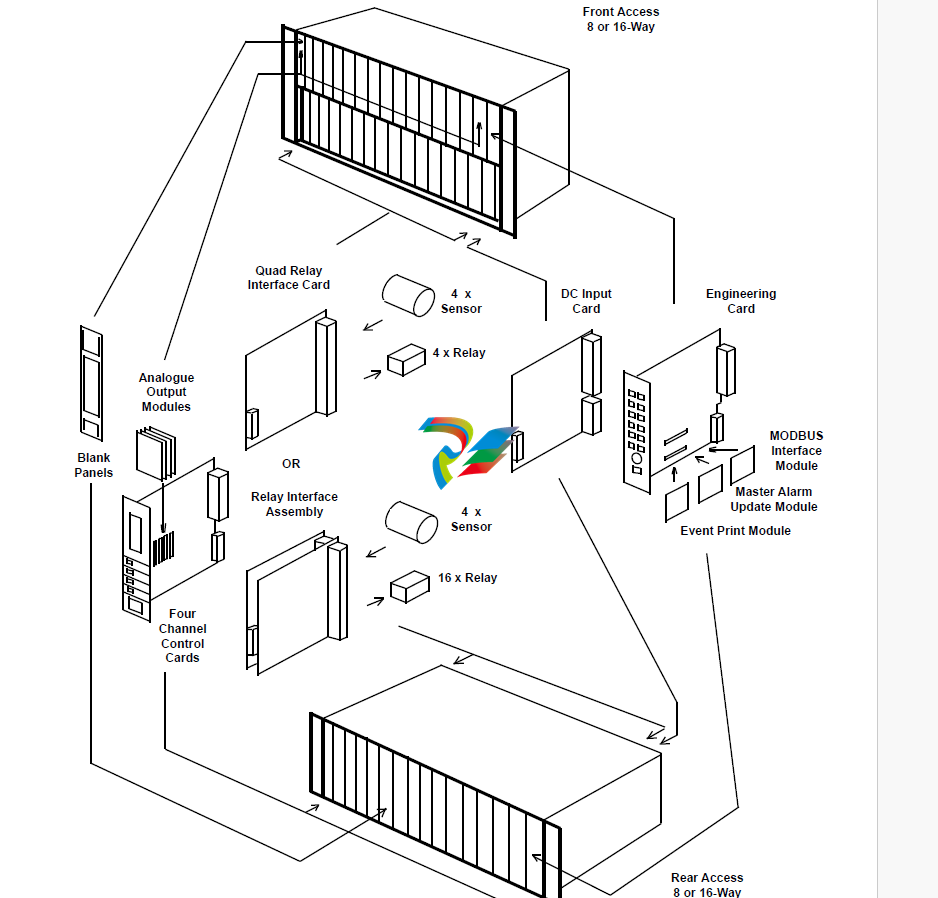

System Architecture & Components

The 5704 system is built on a modular, rack-based platform, allowing for flexible configurations tailored to specific application needs. The core components are housed in either a full 19" or half-width 19" sub-rack, available in 3U (rear access wiring) or 6U (front access wiring) formats.

The main components include:

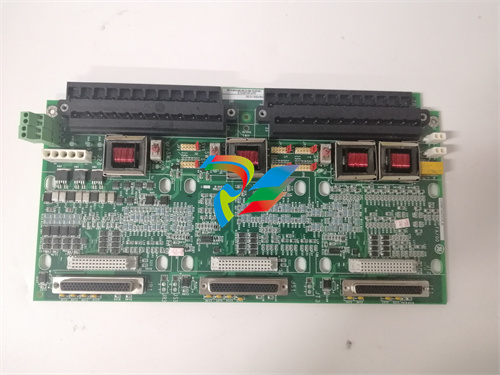

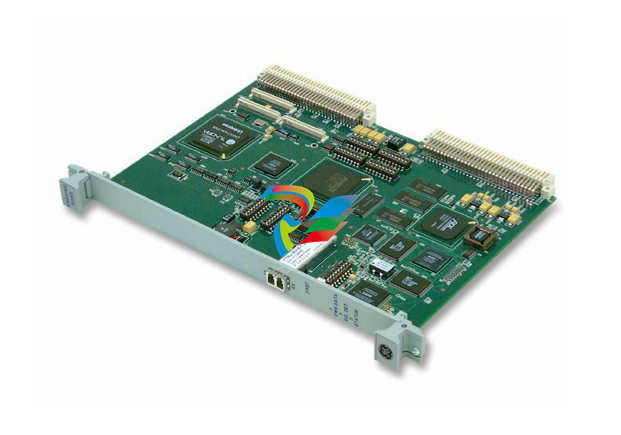

Four Channel Control Card (Part No. 05704-A-0144 / 0145): This is the central processing unit for a group of four sensors. It is a 1-inch wide, plug-in module responsible for sensor drive, signal processing, gas level display, and alarm logic. Two main versions are available:

Catalytic Input Card: For use with catalytic bead (pellistor) combustible gas sensors.

4-20mA Input Card: For use with any gas detector or transmitter that provides a standard 4-20mA analog signal.

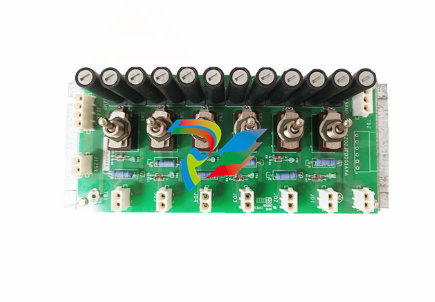

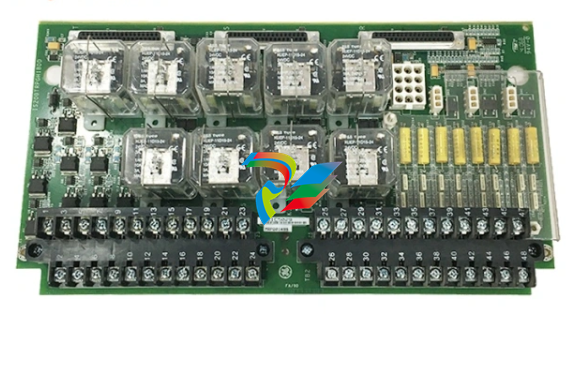

Quad Relay Interface Card (Part No. 05704-A-0121): This card serves as the physical interface between a Four Channel Control Card and the field wiring. It provides terminals for sensor connections and includes four standard single-pole changeover (SPCO) relays for alarm outputs.

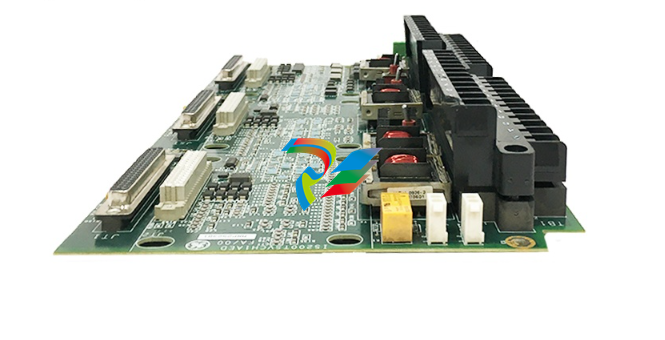

Expansion Relay Card: To increase the number of physical relay outputs, an Expansion Relay Card can be attached to the Quad Relay Interface Card, forming a Relay Interface Assembly. This expands the relay count from four to sixteen for a group of four channels.

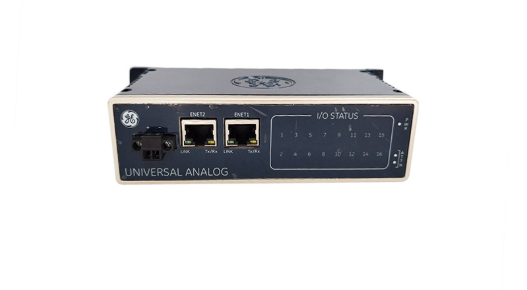

Engineering Card (Part No. 05701-A-0361): A single Engineering Card is fitted in each rack. It serves as the primary user interface for commissioning, calibration, and maintenance. It features push-buttons for local operation and an RS232 serial port for connection to a PC (for configuration software) or a printer.

DC Input Card: Manages the 24V DC power distribution to the rack's backplane.

Optional Modules: The system can be expanded with modules that plug into the Engineering Card, such as a Modbus Interface Module (RS232 or RS485/422) for digital communication with host systems, or an Event Printing Module.

Key Features & Capabilities

High-Density Monitoring: Provides up to 64 channels (16 x Four Channel cards) in a standard 19" rack.

Flexible Inputs: Supports both catalytic bridge sensors and industry-standard 4-20mA loop-powered sensors or transmitters.

Advanced Alarm Handling: The system can be configured for complex alarm logic beyond simple individual channel alarms, including:

Zoned Alarms: An alarm from any sensor within a designated physical area.

Master Alarms: A common alarm for any designated channel within a single rack.

Voted Alarms: An alarm that requires simultaneous alarms from multiple channels within a group before activating.

Onboard Relays: Each group of four channels has access to at least four relays, expandable to sixteen, which can be configured for various alarm levels (A1, A2, A3), fault conditions, or inhibit status. Relays can be set as latching/non-latching and normally energized/de-energized.

User Interface: Each Control Card has a backlit LCD for displaying the gas concentration (via digital readout and analog bargraph), channel status, and alarm messages. Status LEDs provide at-a-glance indication of alarms, faults, and inhibit conditions for each channel.

Maintenance & Calibration: All maintenance and calibration functions (Zero, Span, 1st Span for new catalytic sensors) are accessed via the common Engineering Card, which requires an "Engineering Key" to unlock adjustment functions, preventing unauthorized changes.

.jpg)

.jpg)