Honeywell Experion PKS Series C I/O: Technical Summary

Honeywell Experion PKS Series C I/O: Technical Summary

Introduction & Purpose

The Honeywell Experion Series C I/O is a family of modular input/output hardware designed for the Experion Process Knowledge System (PKS). It serves as the interface between the C300/CN100 controllers and field devices, handling all I/O scanning and processing. A key design principle is the separation of I/O processing from control processing, which allows for deterministic I/O scan rates independent of controller loading and supports efficient, high-performance control strategies.

System Architecture

The Series C system is built on a modern, robust architecture:

I/O Link: I/O modules communicate with the C300/CN100 controller over a dedicated, redundant, high-speed I/O Link. This link is significantly faster than the legacy Process Manager I/O (PMIO) link.

IOM and IOTA: The system consists of two main physical components:

I/O Module (IOM): The intelligent part of the assembly that performs the processing.

I/O Termination Assembly (IOTA): The baseplate that the IOM mounts onto. The IOTA provides the terminal blocks for all field wiring, as well as fuses and other conditioning components. This design allows IOMs to be replaced under power without disturbing field wiring.

Redundancy: The platform fully supports optional redundancy for both I/O modules and the I/O Link, enhancing system availability.

Power: The system is powered by a 24V DC subsystem, which can also be configured redundantly.

Key I/O Module Types

The Series C platform offers a comprehensive range of I/O modules to suit various application needs:

Standard Analog & Digital I/O:

Analog Input (AI): Modules for 4-20mA or 1-5V inputs, with and without HART communication protocol support. Both single-ended and differential input IOTAs are available.

Analog Output (AO): 16-channel modules for 4-20mA outputs, with and without HART support.

Digital Input (DI): 32-channel modules for various voltage levels (e.g., 24V DC, 120/240V AC), with features like open-wire detection and Sequence of Events (SOE) capability on specific models.

Digital Output (DO): 32-channel modules for 24V DC, including bussed power and relay output options with electronic short-circuit protection.

Universal Input/Output (UIO and UIO-2):This is a hallmark feature of the Series C platform. The UIO module contains 32 channels that can be individually configured via software as an AI, AO, DI, or DO. This provides immense flexibility in system design, marshalling, and spares management. The newer UIO-2 module offers enhanced features like per-channel HART modems, higher-frequency pulse counting, and advanced diagnostics.

Specialty I/O Modules:

Low Level Analog Input (LLAI / LLMUX): Designed for direct connection to low-voltage sensors like Thermocouples (TC) and RTDs.

Pulse Input Module (PIM): A high-accuracy, 8-channel module for frequency, period, and pulse width measurement from rotating machinery like turbines and flow meters. It is well-suited for custody transfer applications.

Speed Protection Module (SPM) & Servo Valve Positioner Module (SVPM): Specialized modules for turbine control and hydraulic valve applications.

Hardware Form Factors

Honeywell provides the Series C platform in several physical formats to accommodate different installation scenarios:

Standard Series C Cabinets: The default vertical mounting system with integrated power and I/O Link distribution.

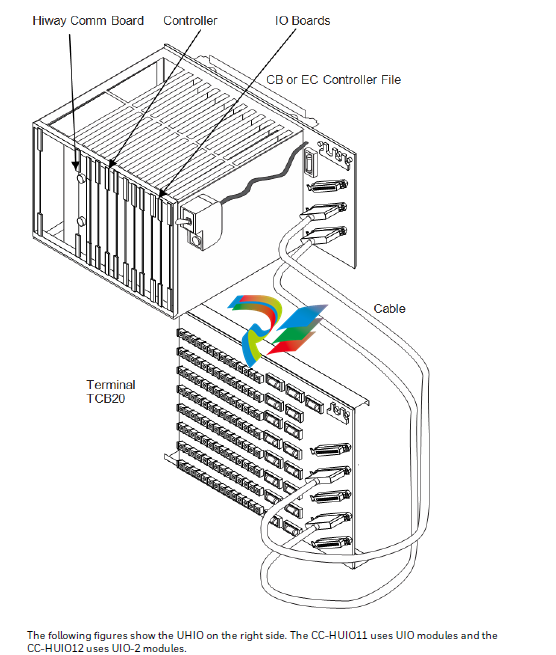

Universal Horizontal Input/Output (UHIO): A unique form factor designed specifically for migrating legacy Honeywell TDC 2000 systems. The UHIO IOTAs are horizontally oriented to fit directly into the existing TDC controller files, allowing reuse of existing cabinets and field wiring terminations (TCBxx panels).

Rail-Mounted UIO: An assembly that allows the versatile UIO module to be mounted vertically on a standard DIN rail for use in non-standard cabinets or distributed applications.

Connectivity & Hazardous Area Support

Remote I/O: The I/O Link can be extended over long distances (up to 10 km) using Fiber Optic Extenders (FOE), enabling distributed I/O architectures.

Galvanically Isolated / Intrinsically Safe (GI/IS): A range of specialized GI/IS IOTAs are available that incorporate MTL isolators. This allows for direct and safe connection to field devices located in hazardous areas (e.g., Zone 2/Div 2) without the need for separate external barriers, simplifying wiring and reducing cabinet space.

Configuration and Maintenance

All Series C I/O modules are configured and integrated into control strategies using the Experion Control Builder software.

The system supports online replacement of modules (RIUP - Removal and Installation Under Power) and provides extensive diagnostics and alarms for troubleshooting and maintenance.

.jpg)

.jpg)

.jpg)

.jpg)

.png)

.jpg)

.jpg)

_lVjBYb.jpg)

.jpg)

.jpg)

.jpg)

.jpg)