Galil Legacy Motion Controllers: Technical Summary

Introduction

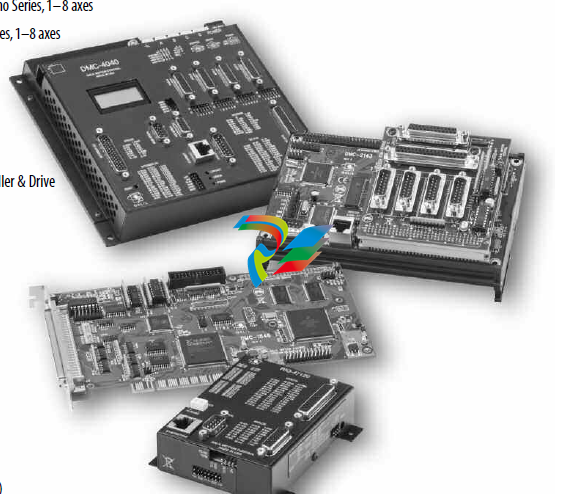

This document provides a technical summary of Galil's legacy motion controllers as detailed in their 2010/2011 product catalog. While succeeded by newer models, these controllers, including the Accelera, Econo, and Pocket PLC series, represent a powerful and cost-effective generation of motion and I/O control solutions. They were offered in various form factors, including stand-alone (box-level) units and bus-based (PCI) cards.

Econo Series Controllers (DMC-41x3, DMC-21x3, DMC-18x2)

The Econo series was designed for cost-sensitive applications without compromising core motion control capabilities.

Models & Form Factors:

DMC-41x3: Stand-alone (box or card-level) with 10/100Base-T Ethernet, USB, and RS232.

DMC-21x3: Stand-alone (card-level) with 10Base-T Ethernet and RS232.

DMC-18x2: PCI bus card.

Axes: Supported 1 to 8 axes, user-configurable for stepper or servo motors.

Performance:

Maximum encoder frequency: Up to 15 MHz for servos (DMC-41x3) or 12 MHz (DMC-21x3/18x2).

Maximum stepper rate: 3 MHz.

Servo loop update time: As low as 125-250 µs.

Features:

Included advanced features like PID compensation, multitasking (up to 8 programs), and various modes of motion (point-to-point, interpolation, gearing, ECAM).

Provided uncommitted digital and analog I/O. The DMC-41x3 notably included 8 analog inputs as standard.

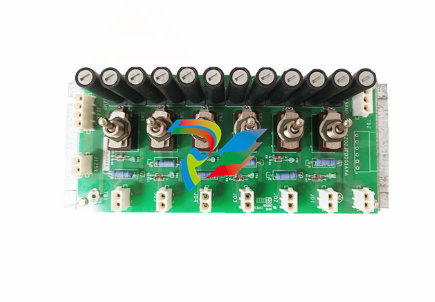

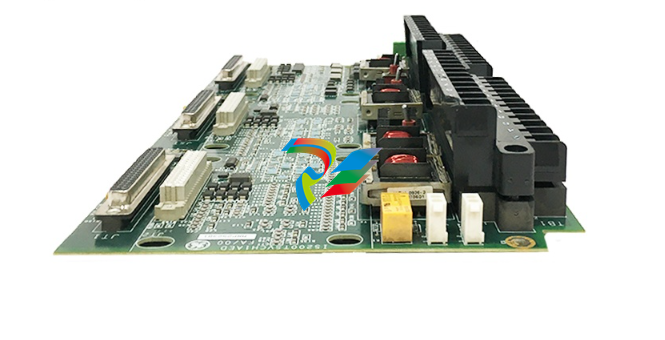

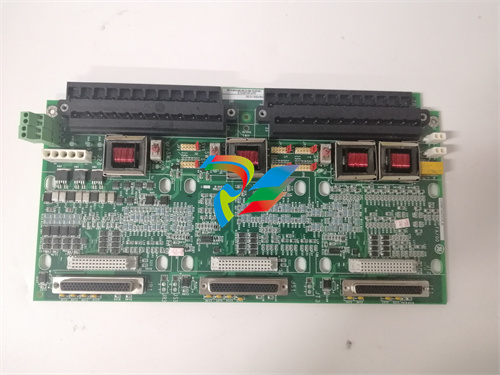

Offered options for integrated multi-axis stepper and servo drives, minimizing wiring and space.

Accelera Series Controllers (DMC-40x0, DMC-18x6)

The Accelera series represented Galil's 5th generation, offering the highest speed and performance for demanding applications.

Models & Form Factors:

DMC-40x0: Stand-alone (box-level) with 10/100Base-T Ethernet and RS232.

DMC-18x6: PCI bus card.

Axes: Supported 1 to 8 axes, configurable for stepper or servo motors.

Performance:

Command Processing: As fast as 40 µs (10x faster than previous generations).

Maximum encoder frequency: Up to 22 MHz.

Maximum stepper rate: 6 MHz.

Servo loop update time: As low as 31 µs.

Features:

Fully loaded with features including optically isolated I/O, dual encoder inputs per servo axis, and 8 uncommitted analog inputs.

The DMC-40x0 supported powerful, internal multi-axis drives for both stepper and servo motors (up to 500W per axis).

Maintained programming compatibility with previous generations while offering significant speed improvements.

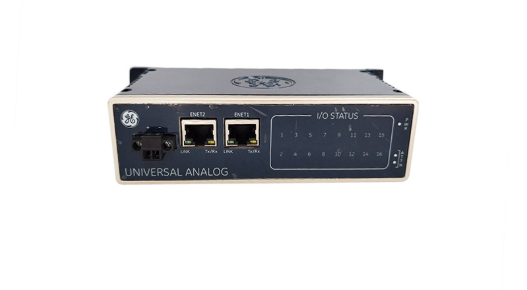

RIO Pocket PLC (RIO-47xxx)

The RIO series provided a compact, intelligent, and cost-effective solution for handling distributed I/O.

Function: A programmable logic controller (PLC) designed for I/O handling and logic control.

I/O Capacity: Packed with a high density of I/O in a small package:

8 configurable analog inputs (12-bit or 16-bit).

8 configurable analog outputs (12-bit or 16-bit).

16 optically isolated digital inputs.

16 optically isolated digital outputs (8 high-power 500mA, 8 low-power 25mA).

Connectivity: Featured a 10/100Base-T Ethernet port and an RS232 port, supporting Modbus/TCP. Could be powered via an external DC supply or Power-over-Ethernet (PoE).

Programming: Programmed with Galil's intuitive command language or with the optional Ladder Interface Software.

Software & Programming

All legacy controllers were programmed using Galil's intuitive, two-letter ASCII command language and supported by a suite of software tools, including:

GalilTools: A modern software environment for setup, tuning (PID), and analysis with real-time scopes.

Ladder Interface Software: For RIO PLCs, converting ladder logic into controller code.

ActiveX Tool Kit: For creating custom Windows-based operator interfaces.

.jpg)

.jpg)