GEMVME51005E Single Board Computer Installation and Use

Safety Summary

The following general safety precautions must be observed during all phases of operation, service, and repair of

this equipment. Failure to comply with these precauti ons or wi th specific warnings elsewhere in t his manual

could result in personal injury or damage to the equipment.

The safety precautions listed below represent warnings of certain dangers of which Emerson is aware. You, as the

user of th e product, sho uld follow these w arnings and al l o ther saf ety precauti ons necessary f or the sa fe

operation of the equipmentin your operating environment.

Ground the Instrument.

To minimize shockhazard, the equipment chassis and enclosure must be connected to an electrical ground. If the

equipment i s su pplied wi th a three-conductor A C p ower cable , the powe r cable m ust be plu gged in to an

approved three-contact electrical outl et, w ith t he grounding wire (g reen/yellow) reliably c onnected t o an

electrical ground (safety ground) at the power outlet. The power jack and mating plug of the power cable meet

International Electrotechnical Commission (IEC) safety standards and local electrical regulatory codes.

Do Not Operate in an Explosive Atmosphere.

Do not operate the equipment in any explosive atmosphere such as in the presence of flammable gases or fumes.

Operation of any electrical equipment in such an environment could result in an explosion and cause injury or

damage.

Keep Away From Live Circuits Inside the Equipment.

Operating personnel must not remove equipment covers. Only Factory Authorized Service Personnel or o ther

qualified service personnel may remove equipment covers for internal subassembly or component replacement

or any internal adjustment. Se rvice pe rsonnel should not replace components with power cable c onnected.

Under certain conditions, dangerous voltages may exist even with the power cable removed. To avoid injuries,

such personnel should always disconnect power and discharge circuits before touching components.

Use Caution When Exposing or Handling a CRT.

Breakage o f a C athode-Ray Tube (CR T) cau ses a h igh-velocity s cattering o f gl ass fra gments (i mplosion). To

prevent CRT implosion, do not handle the CRT and avoid rough handling or jarring of the equipment. Handling of

a CRT should be done only by qualified service personnel using approved safety mask and gloves.

Do Not Substitute Parts or Modify Equipment.

Do not install substitute parts or perform any unauthorized modification of the equipment. Contact your local

Emerson representative for service and repair to ensure that all safety features are maintained.

Observe Warnings in Manual.

Warnings, suc h a s the e xample be low, precede po tentially d angerous proc edures thro ughout this m anual.

Instructions contained in the warnings must be followed. You should also employ all other safety precautions

which you deem necessary for the operation of the equipment in your operating environment.

Warning

To prevent serious injury or death from dangerous voltages, use extreme

caution when handling, testing, and adjusting this equipment and its

components.

Flammability

All Emerson PWBs (printed wiring boards) are manufactured with a flammability rating of 94V-0 by

UL-recognized manufacturers.

EMI Caution

!

Caution

This equipment generates, uses and can radiate electromagnetic energy. It may cause or be

susceptible to electromagnetic interference (EMI) if not installed and used with adequate EMI

protection.

Lithium Battery Caution

This product contains a lithium battery to power the clock and calendar circuitry. Only properly

trained service personnel should remove or install lithium batteries.

!

Caution

Danger of explosion if battery is replaced incorrectly. Replace battery only with the same or

equivalent type recommended by the equipment manufacturer. Dispose of used batteries

according to the manufacturer’s instructions.

Attention

!

Il y a danger d’explosion s’il y a remplacement incorrect de la batterie. Remplacer uniquement

avec une batterie du même type ou d’un type équivalent recommandé par le constructeur.

Mettre au rebut les batteries usagées conformément aux instructions du fabricant.

Vorsicht

!

Explosionsgefahr bei unsachgemäßem Austausch der Batterie. Ersatz nur durch denselben oder

einen vom Hersteller empfohlenen Typ. Entsorgung gebrauchter Batterien nach Angaben des

Herstellers.

CE Notice (European Community)

!

Warning

Warning

This is a Class A product. In a domestic environment, this product may cause radio interference,

in which case the user may be required to take adequate measures.

Emerson products with the CE marking comply with the EMC Directive (89/336/EEC). Compliance

with this directive implies conformity to the following European Norms:

EN55022 “Limits and Methods of Measurement of Radio Interference Characteristics of

Information Technology Equipment”; this product tested to Equipment Class A

EN 300 386 V.1.2.1 “Electromagnetic compatibility and radio spectrum matters (ERM);

Telecommunication network equipment; Electromagnetic compatibility (EMC) requirements”

System products also fulfill EN60950 (product safety) which is essentially the requirement for the

Low Voltage Directive (73/23/EEC).

Board products are tested in a representative system to show compliance with the above

mentioned requirements. A proper installation in a CE-marked system will maintain the required

EMC/safety performance.

In accordance with European Community directives, a “Declaration of Conformity” has been made

and is on file within the European Union. The “Declaration of Conformity” is available on request.

Please contact your sales representative.

The product has been designed to meet the directive on the restriction of the use of certain

hazardous substances in electrical and electronic equipment (RoHS) Directive 2002/95/EC.

The MVME51005E Single Board Computer Installation and Use provides the information you will need

to install and configure your MVME51005E Single Board Computer. It provides specific preparation

and installation information and data applicable to the board. The MVME51005E will hereafter be

referred to as the MVME5100.

The MVME5100 is a high-performance VME single board computer featuring the PowerPlus II

architecture with a choice of processors–either the MPC7410 with AltiVec™ technology for

algorithmic intensive computations or the low-power MPC750.

As of the printing date of this manual, the MVME5100 is available in the configurations shown

below. Note: all models of the MVME5100 are available with either VME Scanbe front panel or IEEE

1101 compatible front panel handles

Model Number Description

450MHz MCP750 Commercial Models

MVME51005E-016x 450MHz MCP750, 512MB ECC SDRAM, 17MB Flash and 1MB L2

cache.

400 and 500 MHz MPC7410 Commercial Models

MVME51105E-216x 400MHz MPC7410, 512MB ECC SDRAM, 17MB Flash and 2MB

L2 cache.

MVME51105E-226x 500 MHz MPC7410, 512MB ECC SDRAM, 17MB Flash and 2MB

L2 cache

MVME712M Compatible I/O

IPMC7126E-002 Multifunction rear I/O PMC module; 8-bit SCSI, Ultra Wide SCSI,

one parallel port, three async and one sync/async serial port.

MVME712M6E Transition module connectors: One DB-25 sync/async serial port,

three DB-25 async serial ports, one AUI connector, one D-36

parallel port, and one 50-pin 8-bit SCSI; includes 3-row DIN P2

adapter module and cable.

MVME761 Compatible I/O

IPMC7616E-002 Multifunction rear I/O PMC module; 8-bit SCSI, one parallel port,

two async and two sync/async serial ports.

MVME7616E-001 Transition module: Two DB-9 async serial port connectors, two HD26 sync/async serial port connectors, one HD-36 parallel port

connector, and one RJ-45 10/100 Ethernet connector; includes 3-

row DIN P2 adapter module and cable (for 8-bit SCSI).

MVME7616E-011 Transition module: Two DB-9 async serial port connectors, two HD26 sync/async serial port connectors, one HD-36 parallel port

connector, and one RJ-45 10/100 Ethernet connector; includes 5-

row DIN P2 adapter module and cable (for 16-bit SCSI); requires

backplane with 5-row DIN connectors.

SIM232DCE5E or DTE EIA-232 DCE or DTE Serial Interface Module.

Overview of Contents

The following paragraphs briefly describe the contents of each chapter.

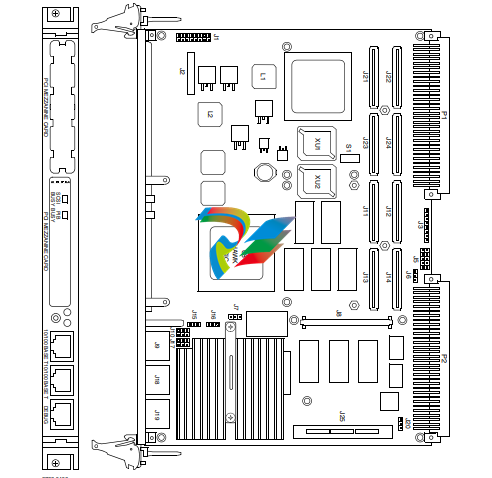

Chapter 1, Hardware Preparation and Installation, provides a description of the MVME5100 and its

main integratedPMC and IPMC boards. The remainder ofthe chapter includes an explanation of the

installation procedure, including preparation and jumper setting information.

Chapter 2, Operation, provides a description of the operational functions of the MVME5100

including tips on applying power, a description of the switch settings, the status indicators, I/O

connectors, and system power up information.

Chapter 3, PPCBug Firmware, provides an explanation of the debugger firmware, PPCBug, on the

MVME5100. The chapter includes an overview of the firmware, a section on how to use PPCBug, a

listing of the initialization steps, a brief explanation of thetwomain configuration commands CNFG

and ENV, and a description of the standard configuration parameters. A listing of the basic

commands are also provided.

Chapter 4, Functional Description, provides a summary of the MVME5100 features, a block diagram,

and a description of the major functional areas.

Chapter 5, RAM500 Memory Expansion Module, provides a description of the RAM500 Memory

Expansion Module, a list of features, a block diagram of the module, a table of memory size

allocations, an installation procedure, and pinouts of the module’s top and bottom side

connectors.

Chapter 6, Pin Assignments, provides a listing of all connector and header pin assignments for the

MVME5100.

provides a description of the memory maps on the

MVME5100 including tables of default processor memory maps, suggested CHRP memory maps

and Hawk PPC register values for suggested memory maps. The remainder of the chapter provides

some programming considerations.

Appendix A, Specifications, provides the standard specifications for the MVME5100, as well as some

general information on cooling.

Appendix B, Troubleshooting, provides a brief explanation of the possible resolutions for basic error

conditions.

Appendix C, Thermal Analysis, gives systems integrators the information necessary to conduct

thermal evaluations of the board in their specific system configuration.

Appendix D, Related Documentation, provides a listing of related documentation for the MVME5100,

including vendor documentation and industry related specifications.

Comments and Suggestions

We welcome and appreciate your comments on our documentation. We want to know what you

think about our manuals and how we can make them better.

Mail comments to us by filling out the following online form:

http://www.emersonnetworkpowerembeddedcomputing.com/ > Contact Us > Online Form

In “Area of Interest” select “Technical Documentation”. Be sure to include the title, part number,

and revision of the manual and tell us how you used it.

Conventions Used in This Manual

The following typographical conventions are used in this document:

bold

is used for user input that you type just as it appears; it is also used for

commands, options and arguments to commands, and names of

programs, directories and files.

italic

is used for names of variables to which you assign values. Italic is also

used for comments in screen displays and examples, and to introduce

new terms.

courier

is used for system output (for example, screen displays, reports),

examples, and system prompts.

<Enter>, <Return> or <CR>

<CR> represents the carriage return or Enter key.

represents the Control key. Execute control characters by pressing the

Ctrl key and the letter simultaneously, for example, Ctrl-d.

Terminology

A character precedes a data or address parameter to specify the numeric format, as follows (if not

specified, the format is hexadecimal):

An asterisk (*) following a signal name for signals that are level significant denotes that the signal is

true or valid when the signal is low.

An asterisk (*) following a signal name for signals that are edge significant denotes that the actions

initiated by that signal occur on high to low transition.

In this manual, assertion and negation are used to specify forcing a signal to a particular state. In

particular, assertion and assert refer to a signal that is active or true; negation and negate indicate a

signal that is inactive or false. These terms are used independently of the voltage level (high or low)

that they represent. Data and address sizes are defined as follows:

0x Specifies a hexadecimal number

% Specifies a binary number

& Specifies a decimal number

Byte 8 bits, numbered 0 through 7, with bit 0 being the least significant.

Half word 16 bits, numbered 0 through 15, with bit 0 being the least

significant.

Word 32 bits, numbered 0 through 31, with bit 0 being the least

significant.

Double word 64 bits, numbered 0 through 63, with bit 0 being the least

significant.

Introduction

This chapter provides information on hardware preparation and installation for the MVME5100

Series of Single Board Computers.

Note Unless otherwise specified, the designation “MVME5100” refers to all models of the

MVME5100-series Single Board Computers.

Getting Started

The following subsections include information helpful in preparing your equipment. It includes and

overview of the MVME5100, any equipment needed to complete the installation, and unpacking

instructions.

Overview and Equipment Requirements

The MVME5100 interfaces to a VMEbus system via its P1 and P2 connectors and contains two IEEE

1386.1 PCI Mezzanine Card (PMC) Slots. The PMC Slots are 64-bit and support both front and rear

I/O.

Additionally, the MVME5100 is user configurable by setting on-board jumpers. Two I/O modes are

possible: PMC mode or SBC mode (also called 761 or IPMC mode). The SBC mode uses the IPMC712

I/O PMC and the MVME712M Transiton Module, or the IPMC761 I/O PMC and the MVME761

Transition Module. The SBC mode is backwards compatible with the MVME761 transition card and

the P2 adapter card (excluding PMC I/O routing) used on the MVME2600/2700 product. This mode

is accomplished by configuring the on-board jumpers and by attaching an IPMC761 PMC in PMC

slot 1. Secondary Ethernet is configured to the rear.

PMC mode is backwards compatible with the MVME2300/MVME2400 and is accomplished by

simply configuring the on-board jumpers.

The following equipment list is appropriate for use in an MVME5100 system:

❏ PMCspan PCI expansion mezzanine module (mates with MVME5100)

❏ Peripheral Component Interconnect (PCI) Mezzanine Cards (PMCs) (installed on an

MVME5100 board)

❏ RAM500 memory mezzanine modules (installed on an MVME5100 board)

❏ VME system enclosure

❏ System console terminal

❏ Disk drives (and/or other I/O) and controllers

Unpacking Instructions

Avoid touching areas of integrated circuitry; static discharge can damage these

circuits.

Note If the shipping carton(s) is/are damaged upon receipt, request that the carrier's agent be

present during the unpacking and inspection of the equipment.

Use ESD

Wrist Strap

Emerson strongly recommends that you use an antistatic wrist strap and a

conductive foam pad when installing or upgrading a system.

Electronic components, such as disk drives, computer boards and memory

modules, can be extremely sensitive to electrostatic discharge (ESD). After

removing the component from its protective wrapper or from the system, place

the component on a grounded, static-free, and adequately protected working

surface. Do not slide the component over any surface. In the case of a Printed

Circuit Board (PCB), place the board with the component side facing up.

If an ESD station is not available, you can avoid damage resulting from ESD by

wearing an antistatic wrist strap (available locally) that is attached to an active

electrical ground.

Note A system chassis may not be a suitable grounding source if it is unplugged.

Preparation

This section includes subsections on hardware configuration that may need to be performed

immediately before and after board installation. It includes a brief reminder on setting bits in

control registers, setting jumpers for the appropriate configuration, and other VME data

considerations.

Hardware Configuration

To produce the desired board configuration and to ensure proper operation of the MVME5100, it

may be necessary to perform certain modifications before and after installation. The following

paragraphs discuss the preparation of the MVME5100 hardware components prior to installing

them into a chassis and connecting them.

A software readable header/ switch register (S1) is available on the MVME5100. This switch is not

defined by the hardware and it is shipped in the OFF position, as are all the switches on this board.

This S1 switch is available for user-specific configuration needs via the control registers.

The MVME5100 provides software control over most of its options by setting bits in control

registers. After installing it in a system, you can modify its configuration. For additional

information on the board’s control registers, refer to the MVME5100 Single Board Computer

Programmer's Reference Guide listed in Appendix D, Related Documentation.

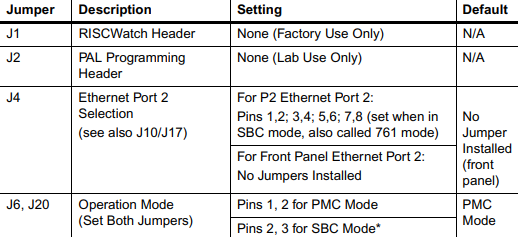

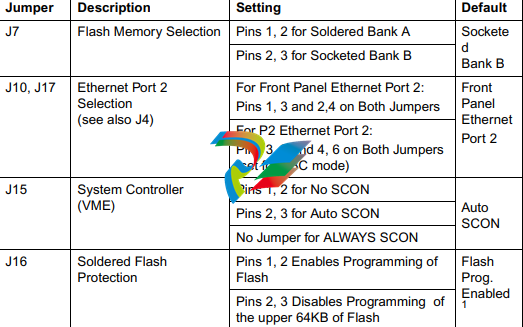

It is important to note that some options are not software-programmable. These specific options

are controlled through manual installation or removal of jumpers, and in some cases, the addition

of other interface modules on the MVME5100. The following table lists the manually configured

jumpers on the MVME5100, and their default settings.

If you are resetting the board jumpers from their default settings, it is important to verify that all

settings are reset properly. For example, the SBC mode requires setting jumpers 4, 10 and 17 for

rear Ethernet functions, but it also requires resetting jumpers J6 and J20. Neglecting to reset J6 and

J20 could damage or destroy subsequent PMCs or PrPMCs installed on the base board at power-up.

Table 1-1. Manually Configured Headers/Jumpers (continued)

Introduction

This chapter provides information on hardware preparation and installation for the MVME5100

Series of Single Board Computers.

Note Unless otherwise specified, the designation “MVME5100” refers to all models of the

MVME5100-series Single Board Computers.

Getting Started

The following subsections include information helpful in preparing your equipment. It includes and

overview of the MVME5100, any equipment needed to complete the installation, and unpacking

instructions.

Overview and Equipment Requirements

The MVME5100 interfaces to a VMEbus system via its P1 and P2 connectors and contains two IEEE

1386.1 PCI Mezzanine Card (PMC) Slots. The PMC Slots are 64-bit and support both front and rear

I/O.

Additionally, the MVME5100 is user configurable by setting on-board jumpers. Two I/O modes are

possible: PMC mode or SBC mode (also called 761 or IPMC mode). The SBC mode uses the IPMC712

I/O PMC and the MVME712M Transiton Module, or the IPMC761 I/O PMC and the MVME761

Transition Module. The SBC mode is backwards compatible with the MVME761 transition card and

the P2 adapter card (excluding PMC I/O routing) used on the MVME2600/2700 product. This mode

is accomplished by configuring the on-board jumpers and by attaching an IPMC761 PMC in PMC

slot 1. Secondary Ethernet is configured to the rear.

PMC mode is backwards compatible with the MVME2300/MVME2400 and is accomplished by

simply configuring the on-board jumpers.

The following equipment list is appropriate for use in an MVME5100 system:

❏ PMCspan PCI expansion mezzanine module (mates with MVME5100)

❏ Peripheral Component Interconnect (PCI) Mezzanine Cards (PMCs) (installed on an

MVME5100 board)

❏ RAM500 memory mezzanine modules (installed on an MVME5100 board)

❏ VME system enclosure

❏ System console terminal

❏ Disk drives (and/or other I/O) and controllers

❏ Operating system (and/or application software)

Unpacking Instructions

Avoid touching areas of integrated circuitry; static discharge can damage these

circuits.

Note If the shipping carton(s) is/are damaged upon receipt, request that the carrier's agent be

present during the unpacking and inspection of the equipment.

Use ESD

Wrist Strap

Emerson strongly recommends that you use an antistatic wrist strap and a

conductive foam pad when installing or upgrading a system.

Electronic components, such as disk drives, computer boards and memory

modules, can be extremely sensitive to electrostatic discharge (ESD). After

removing the component from its protective wrapper or from the system, place

the component on a grounded, static-free, and adequately protected working

surface. Do not slide the component over any surface. In the case of a Printed

Circuit Board (PCB), place the board with the component side facing up.

If an ESD station is not available, you can avoid damage resulting from ESD by

wearing an antistatic wrist strap (available locally) that is attached to an active

electrical ground.

Note A system chassis may not be a suitable grounding source if it is unplugged.

Preparation

This section includes subsections on hardware configuration that may need to be performed

immediately before and after board installation. It includes a brief reminder on setting bits in

control registers, setting jumpers for the appropriate configuration, and other VME data

considerations.

Hardware Configuration

To produce the desired board configuration and to ensure proper operation of the MVME5100, it

may be necessary to perform certain modifications before and after installation. The following

paragraphs discuss the preparation of the MVME5100 hardware components prior to installing

them into a chassis and connecting them.

A software readable header/ switch register (S1) is available on the MVME5100. This switch is not

defined by the hardware and it is shipped in the OFF position, as are all the switches on this board.

This S1 switch is available for user-specific configuration needs via the control registers.

The MVME5100 provides software control over most of its options by setting bits in control

registers. After installing it in a system, you can modify its configuration. For additional

information on the board’s control registers, refer to the MVME5100 Single Board Computer

Programmer's Reference Guide listed in Appendix D, Related Documentation.

It is important to note that some options are not software-programmable. These specific options

are controlled through manual installation or removal of jumpers, and in some cases, the addition

of other interface modules on the MVME5100. The following table lists the manually configured

jumpers on the MVME5100, and their default settings.

If you are resetting the board jumpers from their default settings, it is important to verify that all

settings are reset properly. For example, the SBC mode requires setting jumpers 4, 10 and 17 for

rear Ethernet functions, but it also requires resetting jumpers J6 and J20. Neglecting to reset J6 and

J20 could damage or destroy subsequent PMCs or PrPMCs installed on the base board at power-up.

Table 1-1. Manually Configured Headers/Jumpers

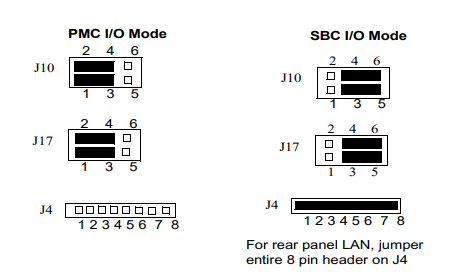

PMC/SBC (761/IPMC) Mode Selection

There are five headers associated with the selection of the PMC or SBC mode: J4, J6 J10,J17 and J20.

Three of these headers are responsible for secondary Ethernet I/O (J4, J10 and J17) to either the

front panel (PMC mode), or to the P2 connector via J4 (SBC mode). The other two headers (J6 and

J20) ensure proper routing of +/- 12V signal routing. The MVME5100 is set at the factory for front

panel I/O: PMC mode (see Table 1-1). The SBC mode should only be selected when using one of the

IPMC-7xx modules in conjunction with the corresponding MVME7xx transition module.

Installation Considerations

The MVME5100 draws power from the VMEbus backplane connectors P1 and P2. Connector P2 is

also used for the upper 16 bits of data in 32-bit transfers, and for the upper 8 address lines in

extended addressing mode. The MVME5100 will not function properly without its main board

connected to VMEbus backplane connectors P1 and P2.

Whether the MVME5100 operates as a VMEbus master or as a VMEbus slave, it is configured for 32

bits of address and 32 bits of data (A32/D32). However, it handles A16 or A24 devices in the

appropriate address ranges. D8 and/or D16 devices in the system must be handled by the

processor software.

If the MVME5100 tries to access off-board resources in a nonexistent location and if the system

does not have a global bus time-out, the MVME5100 waits indefinately for the VMEbus cycle to

complete. This will cause the system to lock up. There is only one situation in which the system

might lack this global bus time-out; that is when the MVME5100 is not the system controller and

there is no global bus time-out elsewhere in the system.

Note Software can also disable the bus timer by setting the appropriate bits in the Universe II

VMEbus interface.

Multiple MVME5100 boards may be installed in a single VME chassis; however, each must have a

unique VMEbus address. Other MPUs on the VMEbus can interrupt, disable, communicate with,

and determine the operational status of the processor(s).

Installation

This section discusses the installation of PMCs onto the MVME5100, installation of PMCspan

modules onto the MVME5100, and the installation of the MVME5100 into a VME chassis.

Note If you have ordered one or more of the optional RAM500 memory mezzanine boards for

the MVME5100, ensure that they are installed on the board prior to proceeding. If they

have not been installed by the factory, and you are installing them yourself, please refer to

Chapter 5, RAM500 Memory Expansion Module, for installation instructions. It is

recommended that the memory mezzainine modules be installed prior to installing other

board accessories, such as PMCs, IPMCs or transition modules