NIOPERATING INSTRUCTIONS AND SPECIFICATIONS NI 9505

This document describes how to use the National Instruments 9505

module and includes specifications and pin assignments for the

NI 9505.

Note The safety guidelines and specifications in this

document are specific to the NI 9505. The other

components in the system may not meet the same safety

ratings and specifications. Refer to the documentation for

each component in the system to determine the safety

ratings and specifications for the entire system.

Caution This product may cause radio interference in

a domestic environment, in which case supplementary

mitigation measures may be required.

Related Information

Safety Guidelines

Operate the NI 9505 only as described in these operating

instructions.

Safety Guidelines for Hazardous Locations

The NI 9505 is suitable for use in Class I, Division 2, Groups A, B,

C, D, T4 hazardous locations; Class I, Zone 2, AEx nA IIC T4 and

Ex nA IIC T4 hazardous locations; and nonhazardous locations

only. Follow these guidelines if you are installing the NI 9505 in a

potentially explosive environment. Not following these guidelines

may result in serious injury or death.

Caution Do not disconnect I/O-side wires or connectors

unless power has been switched off or the area is known to

be nonhazardous.

Caution Do not remove modules unless power has been

switched off or the area is known to be nonhazardous.

Caution Substitution of components may impair

suitability for Class I, Division 2.

Caution For Division 2 and Zone 2 applications, install

the system in an enclosure rated to at least IP 54 as defined

by IEC/EN 60079-15.

Caution For Division 2 and Zone 2 applications, install a

protection device between the input signal and the Vsup

pin. The device must prevent the Vsup-to-channel voltage

from exceeding 42 V if there is a transient overvoltage

condition.

Special Conditions for Hazardous Locations Use in

Europe and Internationally

This equipment has been evaluated as Ex nA IIC T4 Gc equipment

under DEMKO Certificate No. 07 ATEX 0626664X and is IECEx

UL 14.0089X certified. Each module is marked II 3G and is

suitable for use in Zone 2 hazardous locations, in ambient

temperatures of -40 °C Ta 70 °C. If you are using the NI 9505

in Gas Group IIC hazardous locations, you must use the device in

an NI chassis that has been evaluated as Ex nC IIC T4, Ex IIC T4,

Ex nA IIC T4, or Ex nL IIC T4 equipment.

Caution You must make sure that transient disturbances

do not exceed 140% of the rated voltage

Caution The system shall only be used in an area of not

more than Pollution Degree 2, as defined in IEC 60664-1.

Caution The system shall be mounted in an

ATEX/IECEx-certified enclosure with a minimum ingress

protection rating of at least IP54 as defined in

IEC/EN 60079-15.

Caution The enclosure must have a door or cover

accessible only by the use of a tool.

Electromagnetic Compatibility Guidelines

This product was tested and complies with the regulatory

requirements and limits for electromagnetic compatibility (EMC)

as stated in the product specifications. These requirements and

limits are designed to provide reasonable protection against

harmful interference when the product is operated in its intended

operational electromagnetic environment.

This product is intended for use in industrial locations. As such,

there is no guarantee that harmful interference will not occur in

a particular installation, when the product is connected to a test

object, or if the product is used in residential areas. To minimize

the potential for the product to cause interference to radio and

television reception or to experience unacceptable performance

degradation, install and use this product in strict accordance with

the instructions in the product documentation.

Furthermore, any changes or modifications to the product not

expressly approved by National Instruments could void your

authority to operate it under your local regulatory rules.

Caution To ensure compliance with the applicable

regulatory requirements, product installation requires

either special considerations or user-installed, add-on

devices. See the product installation instructions for

further information.

Caution The inputs/outputs of this product can be

damaged if subjected to Electrostatic Discharge (ESD). To

prevent damage, industry-standard ESD prevention

measures must be employed during installation,

maintenance, and operation.

Special Conditions for Marine Applications

Some modules are Lloyd’s Register (LR) Type Approved for

marine applications. To verify Lloyd’s Register certification, go

to ni.com/certification and search for the LR certificate, or

look for the Lloyd’s Register mark on the module.

Caution To meet radio frequency emission requirements

for marine applications, use shielded cables and install the

system in a metal enclosure. Suppression ferrites must be

installed on power supply inputs near power entries to

modules and controllers. Power supply and module cables

must be separated on opposite sides of the enclosure and

must enter and exit through opposing enclosure walls.

NI 9505 Hardware Overview

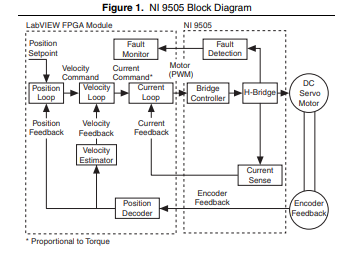

The NI 9505 provides unique flexibility and customization. The

NI 9505 works together with the LabVIEW FPGA Module to

create a highly customizable motor drive or actuator amplifier.

Figure 1 illustrates the functionality of the NI 9505 working in

conjunction with the LabVIEW FPGA Module in a typical motion

control application. Figures 2 and 3 show more detailed versions

of the position, velocity, and current loops implemented in the

LabVIEW FPGA Module. A typical application contains a

position loop, velocity loop, and current loop, implemented in

the LabVIEW FPGA Module block diagram. Depending on the

application, you may not need to use all three loops. The examples

installed in the labviewexamplesCompactRIOModule

SpecificNI 9505 directory illustrate methods for implementing

each of these loops.

The NI 9505 returns the motor or actuator current data to the

LabVIEW FPGA Module for use in a current loop or for

monitoring. The NI 9505 also returns status information such as

drive fault status, VSUP presence, and emergency stop status to the

LabVIEW FPGA Module for use in system monitoring. Refer

to the NI 9505 Reference Help book in the LabVIEW Help,

available by selecting Help»Search the LabVIEW Help, for

more information about the available status information.

The LabVIEW FPGA Module generates a PWM signal and sends

the signal to the NI 9505. The PWM signal is proportional to the

desired current or torque you want to provide to the motor or

actuator. Increasing the PWM duty cycle results in increased

current and thus increased torque.

Quadrature encoder signals pass through the NI 9505 and are

processed in the LabVIEW FPGA Module for use in the position

Hot-Swap Behavior

The NI 9505 is always disabled when it is inserted in the chassis,

regardless of whether VSUP is present or not. You can enable the

drive using the Enable Drive method in software. Refer to the

NI 9505 Reference Help book in the LabVIEW Help, available

by selecting Help»Search the LabVIEW Help, for more

information about enabling the drive.

When the NI 9505 is removed from the chassis while it is enabled,

the power to the motor is removed and the motor decelerates to a

stop based on its own friction.

Power

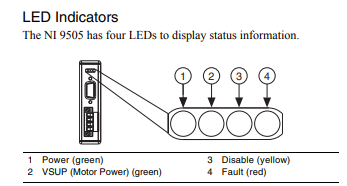

The Power LED (green) illuminates when the NI 9505 is properly

inserted into a powered chassis.

Note The Power LED does not illuminate when the

chassis is in sleep mode.

VSUP

The VSUP LED (green) illuminates when the motor DC power

supply is properly connected and powering the drive.

Disable

The Disable LED (yellow) illuminates when the drive is disabled.

The drive is disabled by default at power-on. You can enable the

drive using the Enable Drive method in software. Refer to the

NI 9505 Reference Help book in the LabVIEW Help, available

by selecting Help»Search the LabVIEW Help, for more

information about this method.

Fault

Caution If the Fault LED is lit, determine the cause of the

fault and correct it before enabling the drive.

The Fault LED (red) illuminates when a fault occurs. A fault

disables the drive. Causes for fault are the following:

Caution VSUP greater than 40 V will result in damage to

the NI 9505.

• Overvoltage

• Undervoltage

• Motor terminal (MOTOR±) short to VSUP

• Motor terminal (MOTOR±) short to COM

• Module temperature exceeds 115 ºC

• Sending commands to the motor before enabling the drive

Note Do not command motor movement until the drive is

enabled with the Enable Drive method. Attempting to

control the motor before it is enabled will result in a fault.

• Violating PWM minimum pulse width requirements. Refer to

the Specifications section for more information about PWM.

Sleep Mode

This module supports a low-power sleep mode. Support for sleep

mode at the system level depends on the chassis that the module is

plugged into. Refer to the chassis manual for information about

support for sleep mode. If the chassis supports sleep mode, refer

to the software help for information about enabling sleep mode.

Visit ni.com/info and enter cseriesdoc for information about

C Series documentation.

Typically, when a system is in sleep mode, you cannot

communicate with the modules. In sleep mode, the system

consumes minimal power and may dissipate less heat than it does

in normal mode. Refer to the Specifications section for more

information about power consumption and thermal dissipation.

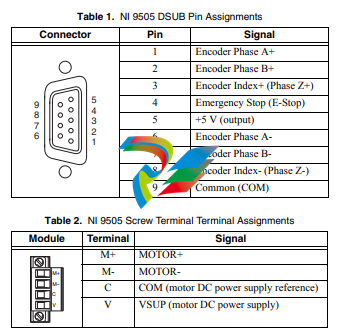

Wiring the NI 9505

The NI 9505 has a 9-pin female DSUB connector that provides

connections for the encoder inputs, a +5 V connection for encoder

power, a connection for an emergency stop input, and a connection

to COM. Refer to Table 1 for the pin assignments.

The NI 9505 also has a screw terminal connector that provides

connections to a motor DC power supply and a DC brushed servo

motor. Connect the positive lead of the power supply to terminal 4,

VSUP, and the negative lead to terminal 3, COM. Refer to Table 2

for the terminal assignments.

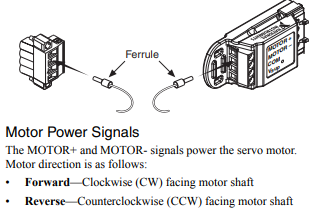

Note You must use 2-wire ferrules to create a secure

connection when connecting more than one wire to a

single terminal on the NI 9505 screw terminal.

Caution Do not turn on or plug in the motor DC power

supply until the screw terminal connector is fully inserted.

Optional Screw Terminal Accessory

Use the NI 9931 Screw Terminal Accessory instead of the

detachable screw terminal connector to increase the output power

of the module at temperatures below 70 ºC. The NI 9931 is

available from ni.com (NI part number 780571-01) or by calling

your National Instruments sales representative. Refer to the

Specifications section for more information. Refer to Figure 5 for

an illustration.

Figure 5. NI 9505 Module with Optional Screw Terminal Accessory

Wiring for High Vibration Applications

National Instruments recommends using ferrules to terminate

wires to the detachable screw terminal connector or the NI 9931

Screw Terminal Accessory when you use the NI 9505 in high

vibration applications. Refer to Figure 6 for an illustration.

Figure 6. 4-Terminal Screw Terminal Connector or

Accessory with a Ferrule

Motor Power Signals

The MOTOR+ and MOTOR- signals power the servo motor.

Motor direction is as follows:

• Forward—Clockwise (CW) facing motor shaft

• Reverse—Counterclockwise (CCW) facing motor shaf

Encoder Signals

The encoder signals consist of a Phase A, Phase B, and Index

(Phase Z) input. The NI 9505 supports differential and

single-ended inputs for Phase A, Phase B, and Index (Phase Z)

signals. Figures 8 and 9 show simplified schematic diagrams of the

encoder input circuit connected to differential and single-ended

inputs. You can also accommodate open-collector output encoders

by using a 1 kΩ pull-up resistor on each line to +5 VDC. Refer to

the Specifications section for more information about the encoder

inputs.

The encoder signals are raw digital input signals. These signals are

used in the LabVIEW FPGA Module for position and/or velocity

feedback. Figures 8 and 9 illustrate the use of the encoder signals

in a position and velocity loop in the LabVIEW FPGA Module.

Refer to the examples installed at labviewexamples

CompactRIOModule SpecificNI 9505 for examples of using

the encoder signals. Refer to the NI 9505 Reference Help book

in the LabVIEW Help, available by selecting Help»Search the

LabVIEW Help, for more information.

If the encoder cable length is greater than 3.05 m (10 ft), use

encoders with differential line driver outputs for your applications.

Power for a +5 V encoder—generated by a power supply inside the

NI 9505—is available on pin 5 of the DSUB connector.

Note The internal power supply is powered through the

Vsup pin.

Closed-loop servo applications require consistent directional

polarity between the motor and encoder for correct operation.

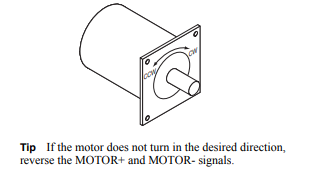

One industry-standard directional polarity is as follows:

• Positive = forward = clockwise (CW) facing motor shaft

• Negative = reverse = counterclockwise (CCW) facing motor

shaft

Refer to Figure 7 for a depiction of clockwise and

counterclockwise rotation. If encoder counting does not behave as

expected, change the encoder polarity in the FPGA or swap the

Phase A and Phase B connections.

When connecting the encoder wiring to the NI 9505, use shielded

wire of at least 24 AWG. You must use cables with twisted pairs

and an overall shield for improved noise immunity. Refer to

Figure 4 for a connection example.

Note Using an unshielded cable may produce noise,

which can corrupt the encoder signals and cause lost

counts, reduced accuracy, or other erroneous encoder and

drive operation.

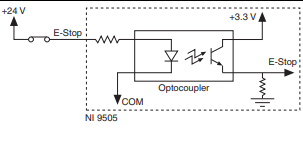

Emergency Stop Signal

The E-Stop signal is an input to the drive from an emergency stop

switch. Figure 10 shows a simplified schematic of the emergency

stop input circuit. When the emergency stop switch is closed,

current flows through the circuit, and the drive is enabled. When

an external event activates the emergency stop switch, the switch

opens and current stops flowing, disabling the drive. The E-Stop

functionality is disabled by default. Refer to the NI 9505 Reference

Help book in the LabVIEW Help, available by selecting Help»

Search the LabVIEW Help, for information about how to enable

this signal using the Enable E-Stop Property.

Figure 10. Emergency Stop Input Circuit

Cable Requirements for EMC Compliance

Use the following guidelines when selecting cables for the

NI 9505:

• Use shielded cables with a low impedance connection to

chassis ground to minimize noise and signal crosstalk.

• Tie the VSUP cable shield to chassis ground at the module side

only.

• Tie the motor cable shield to chassis ground at the motor side

only.

• Tie the encoder cable shield to COM at the encoder side only.

• Wire encoder signals and their ground connections separately

from all other connections to prevent lost encoder counts.

• Route wires along the machine frame to reduce high frequency

noise.

• Add clamp-on ferrites to cables to further reduce emissions.

• Add a balun to the power cable to attenuate conducted and

radiated emissions

Channel-to-COM ..............................0 to +30 VDC max,

Measurement Category I

Isolation

Channel-to-channel ....................None

Channel-to-earth ground

Continuous ...........................60 VDC,

Measurement Category I

Withstand .............................750 Vrms, verified by a 5 s

dielectric withstand test

Measurement Category I is for measurements performed on

circuits not directly connected to the electrical distribution system

referred to as MAINS voltage. MAINS is a hazardous live electrical

supply system that powers equipment. This category is for

measurements of voltages from specially protected secondary

circuits. Such voltage measurements include signal levels, special

equipment, limited-energy parts of equipment, circuits powered by

regulated low-voltage sources, and electronics.

Caution Do not connect the NI 9505 to signals or use for

measurements within Measurement Categories II, III, or IV.

CE Compliance

This product meets the essential requirements of applicable

European directives as follows:

• 2014/35/EU; Low-Voltage Directive (safety)

• 2014/30/EU; Electromagnetic Compatibility Directive (EMC)

• 94/9/EC; Potentially Explosive Atmospheres (ATEX)

Online Product Certification

Refer to the product Declaration of Conformity (DoC) for

additional regulatory compliance information. To obtain product

certifications and the DoC for this product, visit ni.com/

certification, search by module number or product line, and

click the appropriate link in the Certification column.

Shock and Vibration

To meet these specifications, you must panel mount the system and

affix ferrules to the end of the screw terminal wires.

Operating vibration

Random (IEC 60068-2-64).........5 grms, 10 to 500 Hz

Sinusoidal (IEC 60068-2-6) .......5 g, 10 to 500 Hz

Environmental Management

NI is committed to designing and manufacturing products in an

environmentally responsible manner. NI recognizes that

eliminating certain hazardous substances from our products is

beneficial to the environment and to NI customers.

For additional environmental information, refer to the Minimize

Our Environmental Impact web page at ni.com/environment.

This page contains the environmental regulations and directives

with which NI complies, as well as other environmental

information not included in this document.

Waste Electrical and Electronic Equipment (WEEE)

EU Customers At the end of the product life cycle,

all products must be sent to a WEEE recycling center.

For more information about WEEE recycling centers,

National Instruments WEEE initiatives, and compliance

with WEEE Directive 2002/96/EC on Waste and Electronic

Equipment, visit ni.com/environment/weee.

Worldwide Support and Services

The NI website is your complete resource for technical support. At

ni.com/support you have access to everything from

troubleshooting and application development self-help resources

to email and phone assistance from NI Application Engineers.

Visit ni.com/services for NI Factory Installation Services,

repairs, extended warranty, and other services.

Visit ni.com/register to register your NI product. Product

registration facilitates technical support and ensures that you

receive important information updates from NI.

A Declaration of Conformity (DoC) is our claim of compliance

with the Council of the European Communities using the

manufacturer’s declaration of conformity. This system affords the

⬉ᄤֵᙃѻક∵ᶧࠊㅵ⧚ࡲ˄ ⫣Ё RoHS˅

Ёᅶ᠋ National Instruments ヺড়Ё⬉ᄤֵᙃ

ѻકЁ䰤ࠊՓ⫼ᶤѯ᳝ᆇ⠽䋼ᣛҸ (RoHS)DŽ݇Ѣ

National Instruments Ё RoHS ড়㾘ᗻֵᙃˈ䇋ⱏᔩ

ni.com/environment/rohs_chinaDŽ (For information

about China RoHS compliance, go to ni.com/

environment/rohs_china.)