schneiderOperating Manual PacDrive™ C200 / C200 A2 Controller

About this manual

1.1 Introduction

Read and observe this manual before you work on the PacDrive Controller for the first

time. Take particular note of the safety instructions. As described in section 2.2, only

those persons who meet the "Selection and qualification of employees" are allowed to

work on the PacDrive Controller.

A copy of this manual must always be available for personnel who are entrusted to

work on the PacDrive Controller.

This manual is intended to help you use the PacDrive Controller and its intended ap‐

plications safely and properly.

By observing this manual, you will help to

• avoid risks,

• reduce repair costs and down times of the PacDrive Controller,

• increase the life span of the PacDrive Controller

• and increase reliability of the PacDrive Controller.

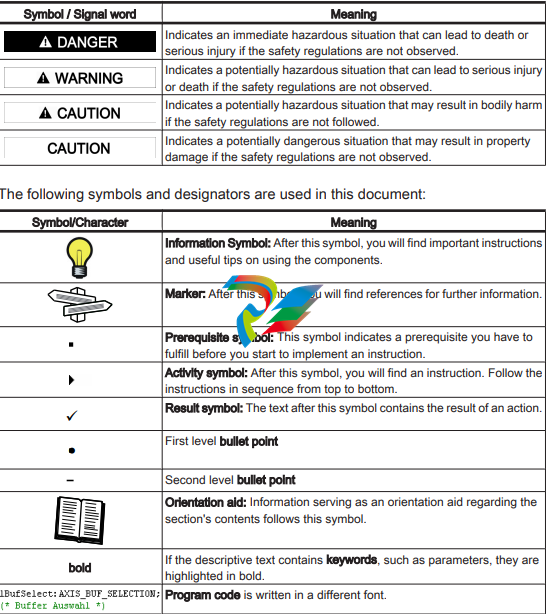

Symbols, designator and display format of safety notes

This manual divides the safety instructions into four various categories.

Hazards and possible results will be categorized using a certain combination of sym‐

bols and signal words.

Notes for working safely with the product

The PacDrive Controller is state of the art and conform to recognized technical safety

regulations. Nevertheless the use of the PacDrive Controller can present a hazard to

life and limb or cause property damage. The following section contains general re‐

quirements for safe work with the PacDrive Controller. Each person who uses or works

on the PacDrive Controller must read and follow these requirements.

2.1 Proper use

Use The PacDrive Controller is intended to be installed in a machine or assembled with

other components to form a machine or system.

What do you

need to ob‐

serve?

Proper use includes that you observe the following points and the resulting rules:

• The regulative, warning and instruction signs on the connected components and

in the switching cabinet

• The warning instructions on the PacDrive Controller on the connected components

and in the switch cabinet

• The inspection and maintenance instructions

• The operating instructions of the other components

• All other documentation

Flawless

State

Operate the PacDrive Controller only when they are in a flawless technical condition.

Observe the regulations, act with safety and hazards in mind If circumstances occur

that impact safety or cause changes in the operating performance of the PacDrive

Controller, switch the PacDrive Controller off immediately and contact the responsible

service staff.

Only original

equipment

must be used

Use only the options and mounting parts specified in the documentation and no thirdparty devices or components that are not expressly approved ELAU recommends. Do

not change the PacDrive Controller inappropriately.

Protection

measures

provide for

Before installing, provide for appropriate protective devices in compliance with the local

and national standards. Do not commission components without accordant protective

devices. After installation, commissioning or repair, test the protective devices used.

Forbidden

environments

The components must not be used in the following environments:

• In dangerous (explosive) atmospheres

• In mobile, movable or floating systems

• In life support systems

• In domestic appliances

Installation

and operating

ambient

You may only use them in accordance with the installation and operating conditions

described in the documentation. The operating conditions at the installation location

must be checked and maintained in accordance with the required technical data (per‐

formance data and ambient conditions). Commissioning is prohibited until it is guar‐

anteed that the usable machine or system in which the PacDrive Controller is installed

meets all requirements of EC Directive 98/37/EC (machinery directive).

In addition, the following standards, directives and regulations are to be observed:

• DIN EN 60204 Safety of machinery: Electrical equipment of machines

• DIN EN 292 Part 1 and Part 2 Safety of machinery: Basic Concepts, General Prin‐

ciples for Design

• DIN EN 50178 Electronic equipment for use in high-current electrical systems

• EMC directive 2004/108/EG

• The generally applicable local and national safety and accident prevention regu‐

lations.

• The rules and regulations on accident prevention and environmental protection that

apply in the country where the product is used

• The applicable laws and ordinances

2.2 Selection and qualification of personnel

Target Audi‐

ence

of this manual

This manual is geared exclusively toward technically qualified personnel, who have

detailed knowledge in the field of automation technology. The description is mainly for

construction and application engineers from the engineering and electro-technics di‐

vision as well as service and commissioning engineers.

Specialist or

trained

staff

Work on the PacDrive Controller may only be carried out by qualified professional or

by trained staff under the instruction and supervision of a qualified person in accord‐

ance with electrical regulations. Professionals are those persons who, as a result of

their training, knowledge, and experience and knowledge of the pertinent regulations,

can

• evaluate the transferred work,

• recognize the meaning of the safety instructions and implement them consistently,

• recognize possible hazards and

• take appropriate safety measures

Rest dangers

Health risks arising from the PacDrive Controller have been reduced by means of

safety technology and design engineering. However a residual risk remains, since the

PacDrive Controller works with electrical voltage and electrical currents.

If activities involve residual risks, a warning instruction is made at the appropriate

points. The note details the potential hazard and its effects and describes preventative

measures to avoid it.

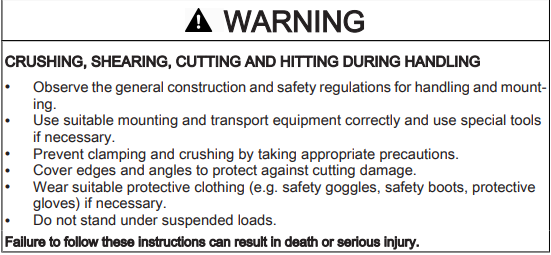

Mounting and handling

Touching electrical parts

DANGER

ELECTRIC SHOCK, FIRE OR EXPLOSION CAUSED BY HIGH VOLTAGE

• Observe the general construction and safety regulations for working on highcurrent electrical systems.

• After installation, check the firm connection of the ground conductor to all elec‐

trical units to ensure that connection complies with the connection diagram.

• Always make sure that the ground conductor is connected when operating elec‐

trical components.

• Before working on electrical equipment with a voltage greater than 50 volts, the

main switch has to be in the "OFF" position and secured, so it cannot be restarted.

• Disconnect devices with a voltage greater than 30 V rms or 42,2 V DC from the

power supply before working on electrical parts.

• Wait at least 5 minutes after switching off before accessing the components.

• Before working on the equipment, discharge the DC bus and use a voltage meter

to make sure that there is no voltage.

• Do not touch the electrical connection points of the components when the device

is switched on.

• Make sure that the drives are at a standstill because potentially fatal voltage can

occur on the motor lines in generator operation.

• Before enabling the device, safely cover the live components to prevent contact.

• Disconnect power connector cables only when the system is deactivated.

• Plug in power connector cables only when the system is deactivated.

• Provide for protection against indirect contact (DIN EN 50178, Section 5.3.2).

• If you are not using prefabricated ELAU cables, check that the assignment of the

new cables complies with the connection diagram of the machine manufacturer.

Failure to follow these instructions will result in death or serious injury.

Dangerous movements

There can be different causes of dangerous movements:

• Missing or faulty homing of the robot mechanics

• Wiring or cabling errors

• Errors in the application program

• Component errors

• Error in the measured value and signal transmitter

• Operation error

Personal safety must be guaranteed by primary equipment monitoring or measures.

Don't just rely on the internal monitoring of the drive components. Monitoring or meas‐

ures should be implemented based on the specific characteristics of the equipment,

in line with a risk and error analysis. This includes the valid safety regulations for the

equipment.

DANGER

DANGEROUS MOVEMENTS

• Prevent entry to a danger zone, e.g. by means protective fencing, mesh guards,

protective covers, or light barriers.

• Ensure the protective devices are properly dimensioned.

• Under no circumstances must the technical safety devices be removed.

• Do not make any modifications to a protective device that may put it out of op‐

eration.

• Protect existing work stations against unauthorized operation.

• Effectively restrict access to the control terminals to allow access only to author‐

ized persons.

• Position EMERGENCY OFF switches so that they are easily accessible and can

be reached quickly.

• Check the functionality of EMERGENCY OFF equipment before start-up and

during maintenance periods.

• Prevent unintentional start-ups by disconnecting the drives from power supply

using the EMERGENCY OFF circuit or using a safe start-up lock out.

• Before accessing the drives or entering the danger zone, safely bring the drives

to a stop.

• While working on the system, power down the electrical equipment using the

main switch and prevent it from being switched back on.

• Secure the system from being switched back on before working on it.

• Avoid operating high-frequency, remote control, and radio devices close to the

system electronics and their feed lines.

• Prior to the initial start-up, check the system and the installation for possible mal‐

functions in all usage scenarios.

• If necessary, carry out a special EMC check of the system.

Failure to follow these instructions will result in death or serious injury

Safe separated extra-low voltage"

PELV Protec‐

tive Extra-Low

Voltage

The signal voltage and control voltage of the PacDriveTM devices are <33 Volts. In this

range, the specification as a PELV system in accordance with IEC 60364-4-41 in‐

cludes a protective measure to guard against direct and indirect contact with danger‐

ous voltage through the safe separation of the primary and secondary sides in the

system/machine. ELAU strongly recommends providing the system/machine with safe

isolation.

DANGER

HIGH ELECTRICAL VOLTAGE DUE TO INCORRECT CONNECTION

• Please ensure that only devices, electrical components or lines that have suffi‐

cient, safe electrical separation from the connected circuits in accordance with

the standards (EN 50178 / 1998 edition - Electronic equipment for use in power

stations) are connected to the signal voltage connectors of this component.

• Ensure that the existing electrical separation is maintained throughout the entire

circuit.

Failure to follow these instructions will result in death or serious injury

FELV Function‐

al Extra-Low

Voltage

When using ELAU Components in systems that do not have safe separation as a

protective measure against direct or indirect contact of dangerous voltages, all con‐

nections and contacts (e.g. PacDrive Controller, Sub-D connector, serial interface) that

do not meet protection class IP2X require a permanent cover. The cover or the device

connection of the connected device must be designed so that it can only be removed

by using a tool. The protective measures have to be adhered on all connected devices

Indicators, control elements, diagnosis

The PacDrive™ System supports the user with its comprehensive diagnostic sys‐

tem.

The diagnostic messages can be read out with the Automation Toolkit EPAS-4 . The

PacDrive™ System contains a powerful message logger in which additional diagnostic

information is recorded.

Diagnostic messages are usually displayed by a control panel on the machine. If an

"error" occurs, read the diagnostic message on this unit and then contact the machine

manufacturer.

Detailed information on diagnosis is available in the Online Help of the Automation

Toolkit EPAS-4.

3.1 Indicators on the PacDrive C200 Controller

If the cover of the PacDrive Controller is closed, you will see four vertically arranged

indicators, which signal different operating- or error conditions.

• pow (control voltage indicator)

• wd (watchdog indicator)

• err (error display)

• bus err (SERCOS real-time bus error indicator)

V00.24.23

10.128.2111.103

0406-0117.0601

enter

In addition to the LED displays, you will receive further information about the operating

status of the PacDrive Controller via the 2-line LCD display.

Line 1 currently used firmware version

Line 2 current IP number of the PacDrive Controller

The horizontal arranged buttons have no function on the PacDrive Controller currently.

pow (control voltage display)

The "pow" LED indicates the state of the control voltage.

OFF The control voltage (24 V DC) is not available or too low.

ON Normal operation; control voltage in normal range

Flashes UPS active

wd (watchdog indicator)

Watchdog is a hardware module to monitor the controller.

OFF Normal operation

ON Fatal error; reset required, reboot system

A "fatal error" is a serious hardware problem or an unexpected software problem.

When a "fatal error" occurs

• the CPU is stopped,

• the optional module is reset,

• the outputs are reset and

• the wd (watchdog) relay outputs are opened.

err (error display)

The error LED (err) indicates errors. The following table lists the possible display con‐

ditions and their accompanying error descriptions.

OFF Normal operation

Flashes slowly (1.7 Hz) Error of class 1, 2, 3, 4 or 5 active

Flashes quickly (10 Hz) The boot of the PacDrive Controller is completed, the last boot failed.

See diagnostic message 209 "last boot failed". The PacDrive Controller

performed a minimal boot.

Flashes fast and slowly alter‐

nately

Firmware download via SERCOS is active

ON A serious error occurred during the current boot.

The err-LED is switched on following "Power on". Once the operating system, user

configuration, user parameters and the IEC program have been loaded and the IEC

program has been started successfully the err LED will switch off again. The boot

procedure is now complete.

bus err (SERCOS real-time bus error indicator)

OFF Normal operation

ON Bus error (problem with fiber-optic cable connection, e.g. transmitting

power is too low or too high, cable break, etc.)

Ethernet LEDs (data throughput indicator and network activity)

On the Ethernet connection (X10) of the PacDrive Controller two LED’s are indicated.

LED yellow: ON PacDrive Controller connected

LED yellow: flashing/flickering Current network traffic

LED yellow: OFF PacDrive Controller not connected

LED green: ON 100 MB connection

LED green: OFF 10 MB connection

After opening the operating cover you have access to the control elements of the Pac‐

Drive Controller:

• CompactFlashTM card slot

• Battery compartment

• [on / off] button

• [reset] button

3.2 CompactFlashTM card slot

The CompactFlash™ card slot is the entry for the permanent data memory (CF™ card)

of the PacDrive Controller.

▶ Switch off the PacDrive Controller.

▶ Hold the CF™ card with your thumb and forefinger and pull it out of the slot.

▶ To insert, carefully place the CF™ card on the guide rail and push it into the device.

▶ Push lightly until the card clicks in.

3.3 Battery compartment

battery

The battery of the PacDrive Controller buffers controller data (Bios, NVRAM, time,

etc.).

Maintenanceinterval

The battery should be replaced every 6 years. After this period of time the battery must

be replaced. If the device (with battery inserted) is not used for an extended period of

time, you should check/replace the battery.

Measurement This is how you measure the battery:

▶ Replace battery and continue with the manual measurement

or

▶ observe the diagnostic message "037 Battery down“ in the IEC program and dis‐

play it on an HMI (panel), if necessary.

▶ Replace battery three days after the first diagnostic message at the latest.

This is how you replace the battery:

▪ You can exchange the battery while the controller is on or off. There is no data

loss if it is performed while the controller is on. When the controller is switched off,

the time period of the data buffering without a battery is approx. 5 minutes.

WARNING

THERE IS A RISK OF EXPLOSION/FIRE IF THE WRONG BATTERY IS USED

• Only use the type of battery with the following data: 3V Lithium Renata Type

2450N.

Failure to follow these instructions can result in death or serious injury

Use insulated pliers to lightly pull the old battery out of its slot.

CAUTION

DANGER OF EXPLOSION WHEN REMOVING/REPLACING BATTERY

• Use a pair of suitable, insulated pliers.

• When replacing the battery use tools which contain no current conducting

material on the contact points.

• In general, be careful not to short circuit the battery poles.

• Do not recharge, dismantle or place battery in fire.

A non-observance of these instructions can cause bodily injury or damage the equipment.

▶ Carefully place the new battery on the guide and lightly push it into the device.

For ordering information (see 5.6 Type code).

3.4 On- /off / reset of the PacDrive Controller

reset

[reset] button

▶ Press this button to reset the controller and reboot it.

Connected Servo Amplifiers MC-4 have their own [reset] button.