schneiderSystem Planning and Installation Guide for Model PC-E984-3811385 & PC-E984-385D

This guide describes the PC-E984-381 and PC-E984-385/385D Programmable

Logic Controller systems together with system planning information and installation procedures.

For brevity and your convenience, the PC-E984-381/385 controller is referred to

in context as the Model 381 E or 385E. Both Model 381 E and 385E are enhanced

with an extra Modbus Port.. The 385D is a 125 VDC version which is otherwise

just like a 385E.

In the context of this manual, the terms “Programmable Controller” and “Programmable Logic Controller” have been abbreviated to “PLC” for brevity. References to

IBMs ’ personal computer are written out or in context with IBMs ’ initials.

It is necessary to say that the information in this document is subject to change

without notice and should not be construed as a commitment by MODICON, Inc.,

Industrial Automation Systems. MODICON, Inc. assumes no responsibility for any

errors that may appear in this document. Further, no part of this document may be

reproduced in any form or by any means, electronic or mechanical, without the express written permission of MODICON, Inc., Industrial Automation Systems. All

rights reserved.

The following are MODICON, Inc. trademarks:

Modicon@ Pi90 984A 984-380 984-381 E984-381

984-385 E984385 D984-385 Micro 984 984 9848

984-480 E984-480 984-485 E984-485 984-680 ModbusB

984x 984-885 E984-885 984-780 984-785 E984-785

984-785L 984-i 20 984-l 30 984-l 45 984-351 984-455

Modsoft@ Modbus Plus

IBM8 is a registered trademark of International Business Machines, Inc.; IBM PC

is a trademark of International Business Machines, Inc.

0 Copyright 1992 Modicon, Inc.

This manual has been written to help you plan, configure, mount, wire, connect,

check out and, if necessary, troubleshoot your PC-E984_381/385/385D PC system. After reading this publication:

A Control Engineer will be able to identify and physically plan the location and

mounting of system components.

A Plant Electrician/Installer will be able to install, power-up and check out the

system.

A Maintenance Technician will be able to recognize, locate, identify and resolve

or report system failures.

How To Use This Manual

Chapter 1 describes the E984-38x model PC systems ’ functions.

Chapter 2 offers information for planning your installation with Local I/O.

Chapter 3 is an installation procedure for your controller with local I/O.

Appendix A gives system specifications including a summary table of l/O module

specifications.

Appendix B gives Stopped Error Codes, MODBUS cable connector pinouts, a

table of MODICON 381 E/385E/385D system end-user part numbers, Customer

Service/Technical Support telephone numbers, and Installation Verification troubleshooting charts.

GM-MSFT-001

GM-0984-SYS

Modsoft Programmer User Guide

984 Programmable Controller Systems

Manual

Incoming Inspection Guidelines

Procedure Guidelines for inspection

Step 1 Before you do anything, verify your shipment is complete and undamaged. If the shipment is incomplete or

damaged, notify the carrier and your distributor.

Step 2 Remove everything from its packing and check for

physical defects or damage. If the equipment is physically

defective or damaged, notify your MODICON representative.

li7 Note Save shipping materials until installation is complete.

Sending Something Back?

o To the extent possible, use the original packing materials supplied by

MODICON.

o All equipment should be firmly packed so that it cannot move around in its shipping container.

o All equipment should be protected against impact during shipment.

Overview

The Modicon 984 Model 381 E, 385E and 385D Controller is a mid-range Programmable Logic Controller in a modular, expandable, architecture. It employs

Modicon 800 series housings, interfaces and I/O modules. The Model “E” is supported by the same instruction set as the other 984 Controller models and is programmed by the Modicon Modsoft Programming Panel.

IF Note The 385D Model is the same as the 385E except it is the

125VDC version.

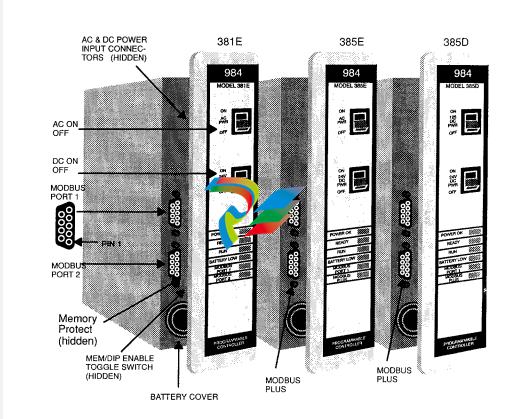

Figure 1 is a perspective view of the 381 E/385E and 385D systems ’ controller

module with built-in power supply. Certain physical features are noted.

System Features

The Model 381 E/385E/385D systems ’ features are described below followed by

somewhat more detailed functional descriptions.

System Capacity

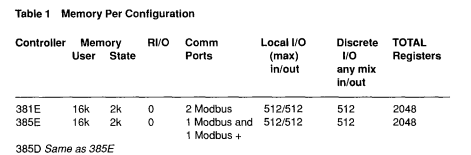

The Model 381 E/385E memory provisions are summarized in Table 1:

The user logic and state RAM support one local drop. This local drop has a maximum I/O module capacity of 21 I/O Modules (19 modules if an auxiliary power

supply is required) and up to 512 discrete points of local I/O (any mix).

Executive NV RAM

The Model “E” controller has its ’ bootable memory and executive software downloaded to Non Volatile RAM during the manufacturing process and is not accessible to the user.

Executive Functionalitv

381 E

Executive ID of 813 (Hex), CPU Clock speed 12 Mhz.

24 DX functions:

MOVE (8), MATRIX (8), JSR, RET, LAB, PID2, EMTH, TBLK, BLKT and

CKSM.

Two standard Modbus ports, Time-of-Day clock, Peer Cop, Local I/O only.

385E

Executive ID of 81C (Hex), CPU Clock speed 12 Mhz.

24 DX functions:

MOVE (8), MATRIX (8), JSR, RET, LAB, PID2, EMTH, TBLK, BLKT and

MSTR.

(MSTR is the user interface to Modbus Plus. It replaces the CKSM function

and uses its opcode.

One Modbus port, One Modbus Plus Port, Time-of-Day clock, Peer Cop,

Local I/O only.

Module Housings

The Model 381 E/385E system uses Modicon 800 series housings for its controller

and I/O modules; specifically, a 19” primary housing with a seven module capacity

or a 27” primary housing with an eleven module capacity.

Primary Enclosure - With the single width Model “E” controller in your primary enclosure, the 19’ and 27” primary enclosures will accommodate up to 6 or IO I/O

modules, respectively.

Secondary Enclosure -The secondary housing will accommodate a one and onehalf wide P810, P800 or P884 auxiliary power supply if a power supply expander

is required and as many I/O modules as there is room remaining.

Specifically, the standard 19” or 27” secondary housings will accommodate five or

nine I/O modules along with a one and one-half wide (two-slot) auxiliary power

supply and a full seven or eleven I/O modules without the power supply.

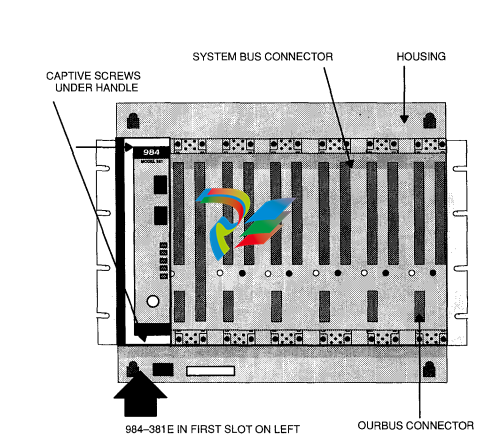

The 1 g-inch primary housing with controller is shown in Figure 2. For simplicitys ’

sake, the 27” housing is not shown in this manual except as required in the illustration on panel mounting dimensions.

Construction

The Model “E” controller is housed in a rugged metal chassis designed to withstand specified temperature and humidity extremes as well as vibration, shock,

and ambient atmospheric conditions consistent with the “factory floor.”

The primary housing employs a shielded backplane which provides for internal

communications within the housing. The backplane protects the internal system

communications from both electromagnetic (EMI) and radio frequency interference

(RFI).

Captive screws secure all modules in the housings and they should be used to insure good electrical contact between the connector at the rear of the module and

backplane in the housing. Key pin protection is also available.

User memory is backed up by a lithium battery which has a one year service life.

It will hold-up for 14 days after the BAT LOW indicator comes on. The batterys ’

installed but unused service life is rated at one year, with a five year shelf life.

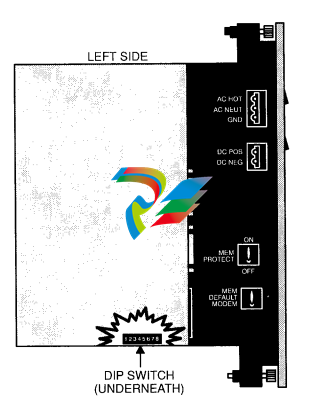

A manually operated memory-protect toggle switch prevents accidental access to

the users ’ program. This switch is located on the left side of the unit, above the 3

position communications toggle switch (see Figure 3).

Power Supply Function (AC and DC)

The Model 381 E/385E and 385D systems ’ controller module comes with a built-in

I/O power supply.

The Model “E” Controllers run on 97 through 276 VAC (47 to 63 Hertz) and 24Vdc.

As shown on Figure 3, Once connected, AC power is then switched ON/OFF with

a front panel rocker switch.

The PLC will also operate continuously on 24Vdc as its an alternate or exclusive

source. Figure 3 shows a primary power input connector for a customer supplied

24Vdc source. Once connected, DC power is then switched ON/OFF with a front

panel rocker switch.

Figure 3 Wiring Connectors, Communications and Memory Switches

The 385D input can range from 105 to 150 VDC with the nominal at 125 VDC controlled by a front panel rocker switch. The 24 VDC option is also available.

Note The primary power DC input feature was not designed, nor is it

suitable as an automatic battery backup provision in the event of an AC

outage. This is because the controllers ’ externally sourced DC input

joins with the AC.sourced, internally produced DC. At any given time,

the Controller is taking from the higher of the two DC voltage sources if

there is as little as a 1 V differential. The consequence of this would be

to draw down the DC battery if there were an extended period(s) of reduced AC voltage supply.

8 Controller Introduction

If you want a backup alternative, one could be configured from a user-supplied

DC power supply with its own backup batten and charger combination along with

appropriate monitoring provisions.

Communications Processing Function

The Models 381 E/385E/385D have Modbus capability for data transfer and remote

programming. Through this port, communication processing on the CPU board

can be linked from the controller to supervisory and programming devices such as

a host computer or Modicon programmer. The Modbus port allows you to schedule one Modbus service per scan. The Model 381 has a second Modbus port

which allows you to incorporate your controller into the Modbus network and still

have a free port for connecting your local programming panel The second port on

the 385E and D is for the Modbus Plus network Connection..

Figure 3 illustrated the controller from the left side. The MEM/DEFAULT/MODEM

toggle switch enables your preset communications configuration for Modbus port

1. (For software configuration, refer to software configurator in Panel software

documentation.)

The DIP switch for setting Modbus Plus port parameters is shown at the bottom of

the illustration but access to the DIP switch is actually through the bottom of the

modules ’ case.

Central Processing Unit (CPU) Function

The Model “E” uses 24 bit memory architecture and a 16 bit CPU which is fully

compatible with the Modicon 984 PC instruction set, solves user logic at a nominal

rate of 2.5 ms per thousand nodes of user logic. For special applications, a timeof-day clock is provided on all “E” Models.

Mainframe Status Indicators

Status indicators on the CPU module are:

POWER OK

READY

RUN

BATTERY LOW

MODBUS Port 1

MODBUS Port 2

Green LED: When ON, indicates input power OK and voltage outputs OK. Your l/O power OK is indicated by the

READY LED.

Amber LED: When ON, indicates Controller passed powerup diagnostics. Remains ON in Stopped and Run modes

as long as health status is OK. Indicator is OFF when an

error condition is detected by diagnostics.

Green LED: When ON, indicates Controller is in the RUN

mode and solving logic. If memory checksum fails this light

will blink 3 times for 5 seconds followed by a rest period of

2.5 seconds then the pattern repeats. The controller is in

Kernal mode and needs the executive reloaded.

Red LED: When ON, indicates battery needs to be replaced (14 day holdup from initial indication).

Green LED: When ON, indicates communication processor

has unit address and communications are in progress.

Green LED: When ON, indicates communication processor

has unit address and communications are in progress.

(The port 2 indicator is labeled MODBUS PLUS on the 385E and 385D and

indicates status as:)

MODBUS PLUS Green LED This LED displays a flashing repetitive pattern to indicate the node status:

NORMAL flashes every 160 msec.

MONITOR NETWORK flashes at one

second intervals. Is in offline state receive only.

NOT RECEIVING TOKEN flashes two times then is off for

two seconds.

SOLE STATION flashes three times then is off for 1.7 seconds.

DUPLICATE NODE ADDRESS flashes four times then is

off for 1.4 seconds.

Overview

The 381 E/385E and 385D Controller is designed to work with your Modicon Modsoft programming panel; Modicon 800 series housings, interfaces and I/O modules.

The site planner must also consider the peripheral equipment (such as a Programming panel, CRT monitor, or printer) when preparing an installation plan for

the site. Refer to the appropriate Modicon publications for site preparation procedures for related equipment.

Space Requirements

For the primary module housing, allow 12 inch clearance to the left so installer can

see power supply connectors. Allow 6 inches on the top and side of the housing

for convection cooling in vertical mounting situations. Allow 12 inch of clearance

at the bottom of the Controller for cable access.

For all other housings, allow 6 inches on the top and sides of each housing for unobstructed cooling airflow in vertical mounting situations.

Also consider installation and physical access for removal of the modules as well

as subsequent service including the connection and detachment of signal and

power cables when required.

The primary housing may be separated up to 12 feet from the secondary housing

depending only on the on the cable length employed.

Primary Power Lines

In addition to service access, distance to power sources has to be considered in

planning your controller installation. In addition to cable routing considerations,

good practices dictate that the power lines be dedicated to the PC installation to

minimize problems that sometimes arise when sharing AC power with electrically

noisy equipment.

Finally, plan to install a service loop and a cable restraint as the primary power

cable as the connector is not locked in place.

Environmental Requirements

In planning for controller installation, consideration should be given to the environment around the controller. Although designed for a harsh industrial environment

and able to withstand factors that would harm other types of electronic equipment,

problems can be avoided by not placing the controller and its related equipment in

an operating area where there is high ambient temperature, acidic atmosphere, vibration, dust, and dirt if it can be avoided.

Mounting Hardware Requirements

After deciding on the final location of the Controller, its associated equipment and

cables, you should plan for related mounting hardware. This would include such

items as: nut and bolt combinations, flat and star washers, housings, mounting

surface, ground straps and system ground connections.

Mounting bolts are NOT provided. The recommended mounting bolts are

0.312-24 UNF-2B (insert or tapped) stainless steel (#8-l 3-SS).

he 984-381 El385E and 385D system housing can be panel/bulkhead mounted

or rack mounted as described in the following text.

Panel or Bulkhead Mounting

As shown in Figure 4 below, the H819 housing has keyholes at the top and bottom

of the housing for bulkhead mounting purposes. The keyholes are sized for

5/16-inch bolts. The recommended ground point is also shown.