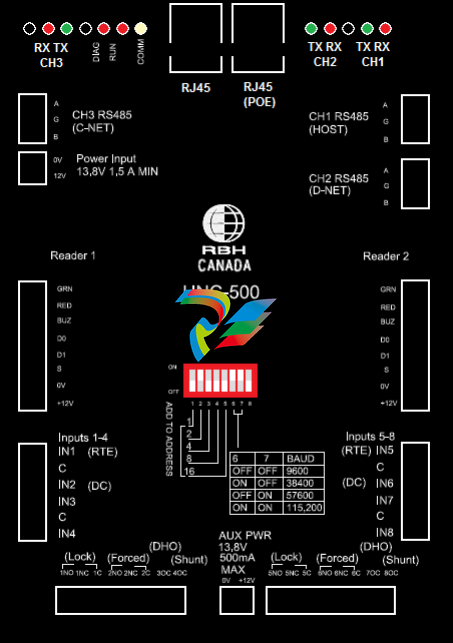

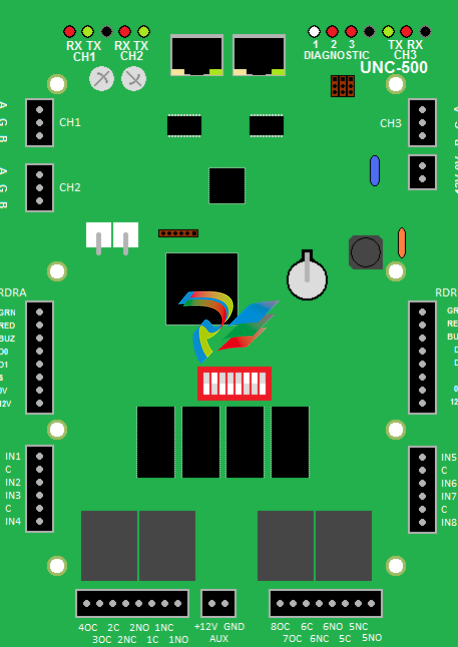

AXIOMUNC500 Silkscreen Legend

The UNC500 has been designed to take over the functionality of the Axiom NC100 (network controller),

an RC-2 (reader controller) and an LIF (local area network interface). The network interface can also

contain a POE (power over Ethernet) converter.

Communication

The UNC500 has three RS485 ports and an Ethernet 10/100 interface. Depending on the hardware

configuration all three channels may not be available. Communications from the host computer running

Axiom software can be achieved in the following ways; either via Ethernet through a socket interface or

via RS485 through a direct connection to a designated channel. The Ethernet interface may be single or

dual ported 10/100 Mbs, depending on how the board is configured. The UNC500‟s RS485 channels 1,

2, or 3 may be programmed as „HOST‟, „DNET‟, „NCNET‟, or „CNET‟. Use the DIP switch to select

baud rate for Host communications as 9600, 38400, 57600, or 115200.

Networks

There are three networks supported by the UNC500 these are:

1) Host Communications through the Ethernet or direct connection.

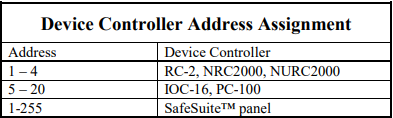

2) Device Communications for devices such as additional RC-2s starting at address 2, Alarm Keypads,

IOC-16 controllers, and PC100.

3) Controller Communications for controllers such as additional UNC500s or for NC100s via:

a. NCNET a protocol designed for RS485 communications between UNC500‟s only.

b. CNET for connection with NC100‟s.

Outputs

There are four form C relays and four open collector outputs that can be programmed as general purpose

or default applications. Although the contacts are rated at 12 amperes at 125vac the surge protectors

prevent voltages greater then 40vac or 56vdc from being applied. The recommended use of the relays is

to provide isolated outputs for driving electric strikes or magnetic locks at a maximum voltage of 24v.

The open collector outputs are current limited to 100 milli-amperes direct current only.

Auxiliary Power

A thermal fuse protected power output rated at 500 milli-amps 12Vdc.

Inputs

There are eight inputs used for sensor connections. Four are configured as general purpose and four are

either programmed for default application or for general purpose. The software provides configuration

information used to decode the state of the contacts. The following table illustrates the seven circuit type

assignments. Note that when an input is armed it will only report alarm or restore states. All “normal”

states are translated to “restore” and all other states are translated to “alarm”.

Reader Interface

Two standard wiegand interfaces provide the following connections for typical proximity readers:

1) Thermal fuse protected power (500ma @12vdc).

2) Wiegand data interface.

3) Reader tamper input (s). Initially if open it will be ignored but once a short is connected it will

report a reader tamper alarm whenever the input is opened.

4) LED and beeper outputs are open collector current limited to 100ma.

Battery Charger

The battery charger routes input power from the 12v input source or 15V POE module through a series

power resistor (24 Ω) and constantly monitors the battery voltage. If the battery voltage exceeds 13.8v

the battery charger turns off until the voltage has reached 12v. If the battery terminals are not connected

this could lead to a constant pulsing of the battery charger output and reporting the battery state as battery

– low, battery – normal. To prevent this from happening the battery test cycle is initiated when ten

cycles are counted. If the battery test fails the charger is turned off until a power failure is detected or a

battery is re-applied.

Reverse Battery Protection

A combination of a three ampere diode and a 1.6 amp thermal fuse protects against accidental connection

of a battery in the reverse direction.

Battery Test

A battery test cycle is operator initiated or scheduled. When initiated the charger is turned off and a

24Ω resistor provides a load to the battery for about ten seconds. If during this period the voltage drops

below 10 volts a battery alarm message is sent to the host, otherwise a battery normal message is sent.

Fuse Monitoring

Besides monitoring the battery voltage the UNC500 also monitors the input voltage (DC), auxiliary

voltage (aux) and the reader voltage (reader) and reports to the host whenever the state changes.

Diagnostic LED’s

Each RS485 circuit has a red and green LED to indicate when a signal is received or transmitted.

Diagnostic 1 is a bicolour LED when red indicates receiving data from the host and when green indicates

transmission of data.

Diagnostic 2 will flash slowly when connected to the host and quickly when not connected.

Diagnostic 3 will flash when a power problem such as a low battery or low auxiliary power is detected.

Tamper Detection

A tamper wire may be connected to JP1 located close to the power resistors on the board. A short to this

input is normal and an open is alarm.

RAM Memory

The static ram memories hold the database from the host that is downloaded using Axiom software. The

coin cell provides power to these memories as well as the real time clock.

Flash Memory

The UNC500 also has flash memory that is used for set-up parameters and firmware. Firmware may be

upgraded using two methodologies for the whole application or just the formats. To upgrade the whole

application the software will select the network controller and pass an RBH file. To upgrade just the

formats the software will select the first RC-2 device and pass a different RBH file.

The AxiomV™ access control system consists of one or more network controllers (NC-100 or UNC500).

All information required by the controller is downloaded from the PC and stored locally non-volatile

flash memory. This information includes configuration data, cardholder records, access levels,

schedules, and all other records necessary for the operation of the system. The controller operates

independent of the PC and all decision-making is performed locally, even in the event of total power loss.

The UNC500 contains a powerful 32-bit micro-controller and has either 2Mb, 4Mb, or 8Mb of RAM.

Connection Details

Power Input

The UNC500 controller requires 13.8vdc to be supplied from an external source.

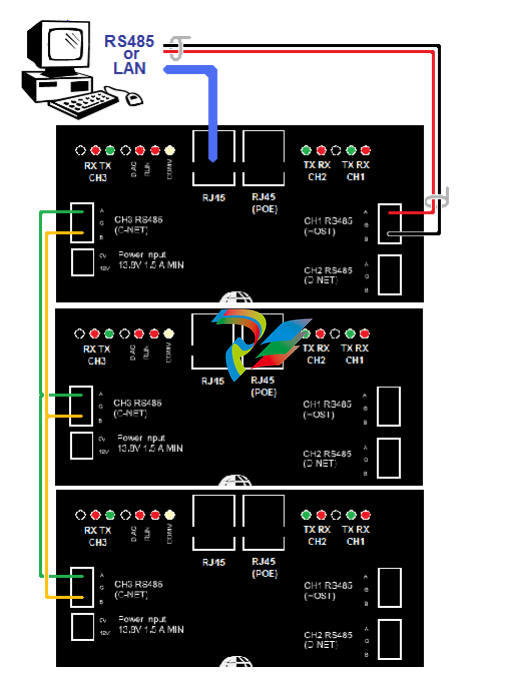

CH1 RS485 (HOST)

The Host port connects the UNC500 to a PC through an RS485 interface.

CH2 RS485 (D-NET)

The D-NET (Device Network) connects local device controllers (RC-2, IOC-16,

SafeSuite Panels, NRC2000, or NURC2000) to the UNC500 controller on a high-speed

bi-directional RS485 network. Connect CH2 on the UNC500 to CH1 on the first device

controller, and then connect it to CH1 on the next device controller on the D-NET and so

on. (see the D-NET diagram on page16)

CH3 RS485 (NCNET)

The NCNET (Controller Network) connects the UNC500 controller to other on a highspeed bi-directional RS485 network. CH3 on the master controller connects to CH3 on

the next UNC500 on the network or to CH1 on the next NC-100 controller in the

network (if the Arcnet option is added). (see NCNET diagram on page14.)

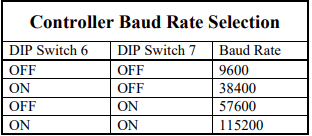

DIP Switch Settings

The UNC500 DIP switch controls the device‟s address and serial port baud rate. The

system must be powered down if the controller address is changed using DIP switches 1

through 5. DIP switch changes for a change in baud rate are processed immediately and

do not require a power down.

Note: To Reset Panel – All DIP switches must be off.

DIP Switch

DIP Switch Function

1 - 5 Controller Address

6,7 Controller Baud Rate

8 not used

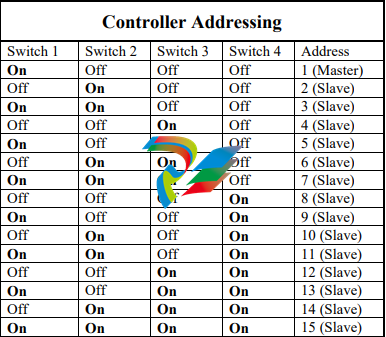

Controller Addressing

Use DIP switches 1, 2, 3, 4, and 5 to select the controller address. The address is binary

coded and the switch settings for all fifteen possible addresses are given below. The

fifth DIP Switch is not usable at this time

Master Controller

Each network must have a single unit designated as the master controller. The master

controller connects to the PC. Setting the DIP switch address to 1 will automatically

designate a unit as the master controller.

Slave Controller

All controllers addressed 2 through 15 are referred to as slave controllers.

CH1 RS485 Port Baud Rate Selection (Master Only)

The controller's serial port baud rate is set with controller DIP switches 6 and 7. This

setting determines the speed used to communicate with the PC; the controller baud rate

must be the same as the baud rate set for the port within the AxiomV™ software. The

default baud rate is 9600.

PC Connection

The master controller is connected to either a serial port on the PC or through the local

Ethernet via a static IP address. The means of communication is configured in the

AxiomV™ software under Network Properties/Port Type.

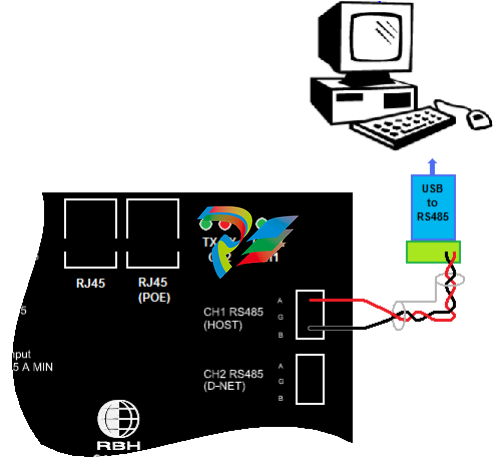

RS485 Connection

The RS485 interface allows the distance between the controller and the PC to be up to

4000 feet (1200 meters) at 38.4k baud. RS485 requires a twisted pair cable 22AWG.

Termination is built into the UNC500 and the USB-RS485 module

PC to UNC500 Connection – RS485 Wiring

Cable Specification

Twisted pair, shielded, 18 to 22 AWG

Maximum Cable Length

4000 feet (1200 meters)

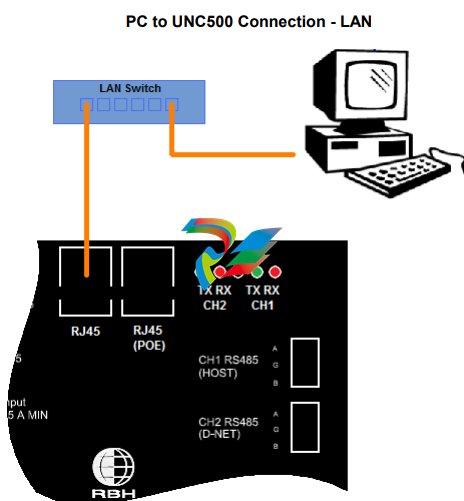

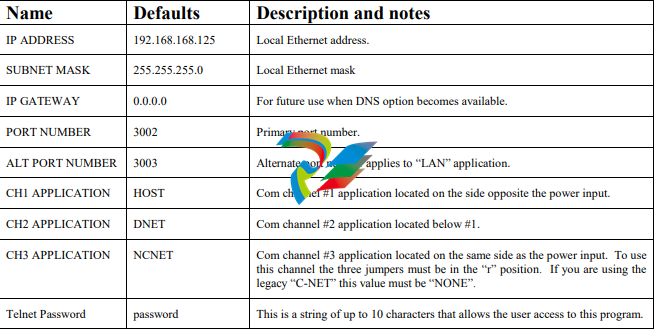

UNC500 TCP/IP Connection

The master controller in some installations may not be directly connected to the PC and

may be linked by the local Ethernet. The system supports a static IP address only

[default address is 192.168.168.125]. To change the IP address of the unit you can either

use IPLocator [a utility program provided by RBH] or Telnet.

To program the UNC500 through Telnet you first have to set all DIP switches off.

Connect to the panel with an Ethernet cable and configure your computer to have IP

address 192.168.168.20 [remember to reconfigure your machine’s IP address back

when you are done]. In the „cmd‟ window type the following „telnet 192.168.168.125‟.

If a connection is made the following message will be displayed.

Telnet Opened on port 23

2 MEG RAM detected.

A password is required in order to change user parameters. The default password is

„password‟. The password can be changed by the user. After entering the password the

following items are available for the use to alter.

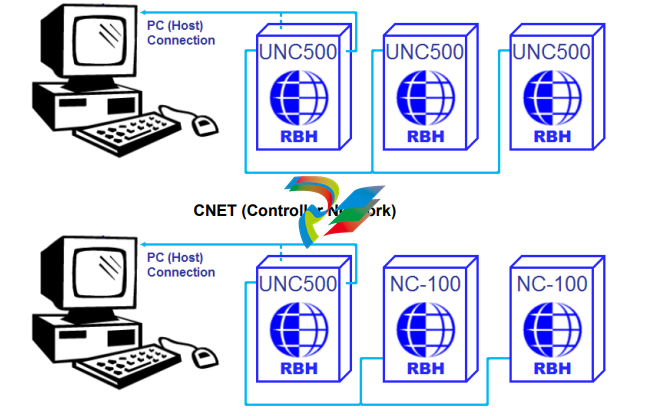

CNET (Controller Network)

Up to fifteen network controllers can be linked together and feed into a single

communication port on the PC. Controller number 1 is designated the master controller

and may be connected to the PC using serial or TCP/IP communications. The remaining

controllers are referred to as slaves and can only communicate to the PC through the

master unit.

NCNET (Controller Network)

UNC500 controller can only be connected to NC-100 controller if the Arcnet option has

been added [C-Net]. To get the Arcnet to function you need to set jumpers JP5, JP6, &

JP7 to „A‟ (for Arcnet), and configure CH3 in the Telnet setup to be „none‟.

When combining UNC500s and NC100s; connect CH2 of the previous panel and CH1 of

the next panel to CH3 (C-NET) of the UNC500. Since the C-Net is a loop; the previous

panel to the first panel is the last panel, and the next panel from the last panel is the first

panel.

NCNET Cable

Use 20 to 22 AWG shielded stranded twisted pair cable for all C-NET connections.

NCNET Maximum Cable Length

The maximum distance for any link in the C-NET is 2500 feet (760 meters) and the total

length cannot exceed 10000 feet (3000 meters).

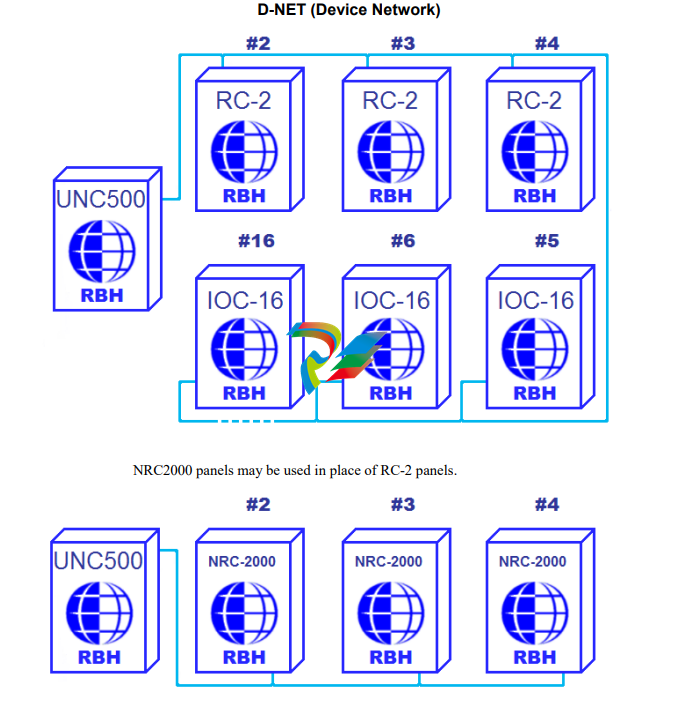

D-NET Device Network

Up to four RC-2 reader controllers, and up to sixteen IOC-16 input/output controllers,

may be connected to each network controller in the C-NET using high speed RS485

communications.

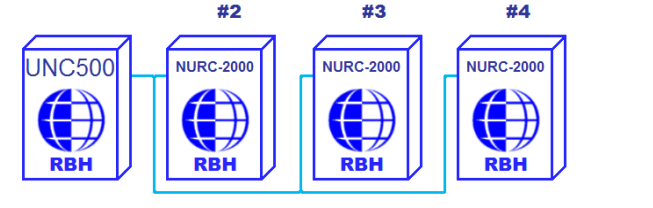

NURC2000 may also be used in place of RC-2 panels.

The D-NET connects IOC-16, RC-2, SafeSuite™ panels, PC-100, NRC2000, and

NURC2000 devices in a daisy chain fashion (parallel connection) to the network

controller. Device controllers do not have to be addressed sequentially. However, using

sequential device controller addressing is recommended as this makes your cabling

diagrams easier to follow and simplifies troubleshooting as the devices are in the correct

numerical sequence.