Condition monitoring system (CMS) software for the VM600 series

From the Vibro-Meter® product line

» Configuration and operation of VM600

hardware (CMC16 and IOC16T condition

monitoring card pairs)

» Automatic data acquisition and storage

» Limit exceedance checking and

event logging

» Online or offline data analysis

» Graphical user interface

» Runs on Windows® Server 2003,

Windows NT, Windows 2000, Windows XP,

Windows Vista and Windows 7 operating

systems

» ANSI SQL-92 compatible

» Optional modules:

Air Gap Module for hydro-turbines

Diagnostics Rule Box

DESCRIPTION

Condition-based maintenance is a predictive

methodology that can be used to improve your asset

(machinery) effectiveness. It enables you to:

• Improve equipment reliability through the effective

prediction of equipment failures

• Minimise downtime through the planning and

scheduling of overhauls

• Maximise component life by avoiding critical known

conditions

• Utilise condition monitoring techniques to maximise

equipment performance.

The VM600 CMS Software from Meggitt Sensing

Systems’ Vibro-Meter ® product line is based on this

principle and is dedicated to the support of technicians,

operators and engineers, enabling them to identify a

problem rapidly, evaluate the situation and determine the

appropriate action to take.

The VM600 CMS Software has a truly modular

architecture that adapts to your specific needs. It

comprises several software modules for use with the

VM600 series hardware

To use the VM600 CMS Software, the system

parameters are configured (once) before the data

acquisition and signal processing starts. Then the results

can be displayed as required, to assist the advanced

analysis and diagnosis of the monitored machinery.

The VM600 CMS Software has the ability to

automatically adapt to the criticality of the machine

status by applying specific data logging scenarios. The

background mode is continuous low-resolution data

acquisition. The scheduled mode is pre-defined highresolution acquisition. The transient mode is

automatically detected and then transient data are

acquired when the speed is out of the "steady" state.

Finally, the manual mode is real-time data acquisition

initiated by the user.

The VM600 CMS Software takes advantage of the

industry standard platforms to allow total adaptability of

the system. It runs under Windows Server 2003,

Windows NT, Windows 2000, Windows XP,

Windows Vista and Windows 7 and has a fully graphical

interface for ease of use. Moreover, the SQL-based data

management server allows you to communicate with any

other SQL-based database.

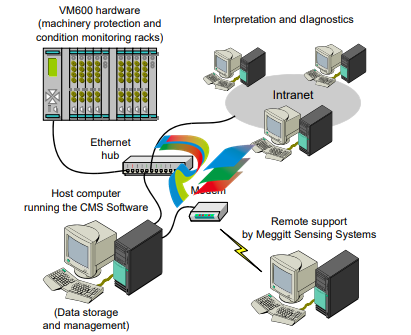

The VM600 CMS Software can run on a single host

computer or on a number of systems connected to the

VM600 rack by network connections. This lets you

decide whether you need to perform the entire

configuration, acquisition, data analysis and

troubleshooting tasks from one location or distribute

them among several workstations. In a distributed

configuration, all specific functions can be performed on

dedicated computers by appropriate personnel. This

classification also enables remote data collection and/or

analysis, and means that configuration and

troubleshooting tasks can be performed via remote

access if necessary.

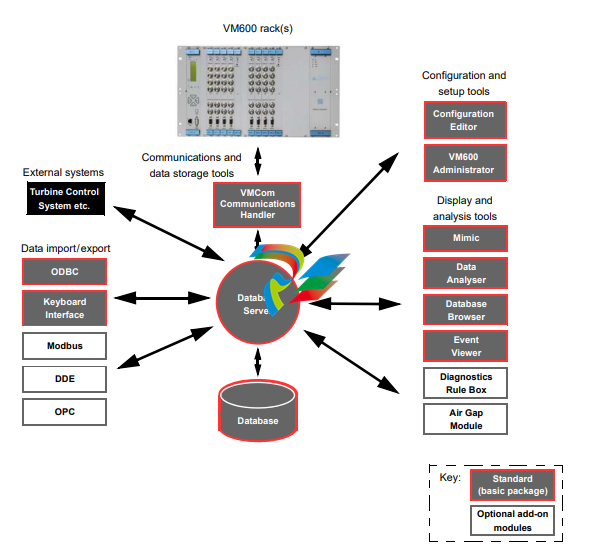

For further applications, the VM600 CMS Software

provides a suite of standard import/export interfaces,

enabling you to transfer data to/from any third-party

system. Your installation benefits are thus the full

flexibility and scalability of the system, because it

enables the correlation of vibration data with other

parameters that are already available from other

devices, so there is no need to re-measure. The

available interfaces are Modbus and OPC (open

connectivity) for communication with field devices such

as PLDs (programmable logic devices) and DCSs

(distributed control systems). The Microsoft ® DDE

(dynamic data exchange) standard is used to exchange

data between the VM600 CMS Software and external

devices. Finally, the ODBC (open database connectivity)

allows your VM600 CMS database to import data from

any ODBC database.

On top of these modules, the Diagnostics Rule Box

enables the user to integrate his machinery knowledge

within the program rules, set conditions on real-time

values, create alarms and alerts, and ultimately generate

automatic actions to adequately warn the user if an

event occurs.

Figure 1: VM600 CMS system architecture – the relationship between the computers running VM600 CMS

and the underlying VM600 hardwar

Figure 2: VM600 CMS Software architecture – the relationship between the VM600 CMS Software application modules,

external interfaces and the underlying VM600 hardware

VM600 condition monitoring system software

CMS

4 / 12 © Meggitt SA / 268-106 / Version 4 / 02.10.2012 / E

SOFTWARE MODULES

The software application modules that make up the VM600 CMS Software client-server architecture are as shown in

Table 1 (below).

VM600 Administrator The VM600 Administrator program is a portal (window) that provides quick and convenient

access to all of the VM600 CMS Software tools, as well as to a number of useful Windows

system tools.

Mimic The Mimic provides the operator with a customised, graphical view of the machinery being

monitored by the VM600 CMS Software system.

The types of data you can visualise directly from the Mimic are "live" data, that is, current

values and current status of both the VM600 hardware and the "offline" systems, as well as

user-requested high-resolution data such as waveforms, spectra and orbit plots.

Configuration Editor The Configuration Editor is used to set up the required configuration of all parameters of the

system, including the configuration details of each single output band, machine-specific

parameters for data logging or transient data and complete VM600 rack configurations.

It stores the system configuration inside the SQL database, from where it can be viewed or

changed by users with sufficient access rights.

It is also a starting point for the advanced configuration of the database, such as preparing

the database to accept "offline" data imported from external systems.

Data Analyser The Data Analyser is used to display measurement data from the SQL database.

It takes data from selected data points defined in the database, applies user- or systemdefined filters to the data, and displays the data as a variety of graphs, plots and charts.

Typical filters that can be applied to data are time, alarm status, machine status, or a userconfigurable filter based on any speed, analog or digital data.

Database Browser The Database Browser is used to display the content of the SQL database in graphical

form.

It can display stored datasets, such as events, spectra, waveforms and orbits as intuitive

time-line representations, thus providing an effective overview of the measurement data

that have been collected. You can then quickly navigate to the dataset of interest using a set

of independent criteria (by point, type of data set, time or alarm state).

Event Viewer The Event Viewer is used to view the events in the SQL database that may have been

created automatically by the system or as defined by users. It displays the available events

in list form, using colour coded, intuitive icons. The window shows either all events present

in the database, or you can choose to set and activate filter criteria in order to limit the

displayed events.

VMCom

Communications Handler

The VMCom program handles the flow of data between VM600 racks and SQL databases.

It communicates with the VM600 CMS hardware and the SQL database.

This program can either be launched manually or configured as a system service, for which

purpose a special service setup utility is included that allows you to configure, create or

delete a Windows service. This is the preferred way of communicating with VM600

hardware for permanent system installations and dedicated on-line condition monitoring

applications.

Table 1: VM600 CMS Software application modules