Vibro-Meter ® VM600 IOC4T input/output card

From the Vibro-Meter® product line

• Signal interface card with 4 dynamic signal

inputs and 2 tachometer (speed) inputs, for the

MPC4 machinery protection card

• Screw-terminal connectors (48 terminals) for all

input/output connections

• Contains 4 relays which can be attributed to

alarm signals, under software control

• 32 fully-programmable open-collector outputs

(jumper selectable) to IRC4 and RLC16 relay

cards

• Buffered “raw” sensor signals and analog

output signals (voltage or current) for vibration

channels

• EMI protection for all inputs and outputs

• Live insertion and removal of cards

(hot-swappable)

• Available in “standard” and “separate circuits”

versions

DESCRIPTION

IOC4T card

The IOC4T input /output card acts as a signal

interface for the VM600 series MPC4 machinery

protection card, from Meggitt’s Vibro-Meter®

product line. It is installed in the rear of a VM600

rack and connects directly to the rack backplane

via two connectors.

Each IOC4T card is associated with a

corresponding MPC4 card and is mounted

directly behind it in the VM600 rack (ABE04x or

ABE056). The IOC4T operates in slave mode and

communicates with the MPC4, through

connector P2, using an Industry Pack (IP)

interface.

The front panel of the IOC4T (rear of the VM600

rack) contains terminal strip connectors for wiring

to the transmission cables coming from

measurement chains (sensors and /or signal

conditioners). The screw-terminal connectors are

also used to input all signals from and output all

signals to any external control system.

The IOC4T card protects all inputs and outputs

against electromagnetic interference (EMI) and

signal surges and also meets electromagnetic

compatibility (EMC) standards.

The IOC4T connects the raw dynamic (vibration)

and speed signals from the sensors to the MPC4.

These signals, once processed, are passed back

to the IOC4T and made available on the terminal

strip on its front panel (rear of VM600). For the

dynamic signals, four on-board digital-to-analog

converters (DACs) provide calibrated signal

outputs in the range 0 to 10 V. In addition, four onboard voltage-to-current converters allow the

signals to be provided as current outputs in the

range 4 to 20 mA (jumper selectable).

The IOC4T contains four local relays that can be

attributed to any specific alarm signals under

software control. For example, these may be used

to signal an MPC4 fault or a problem detected by

a common alarm (Sensor OK, Alarm and Danger)

in a typical application.

In addition, 32 digital signals representing alarms

are passed to the rack backplane and may be

used by optional RLC16 relay cards and / or IRC4

intelligent relay cards mounted in the rack

(jumper selectable).

Applications information

When used as a card pair with an MPC4

machinery protection card, the IOC4T is highly

suitable for machinery monitoring and protection

in a wide range of industrial applications.

For further information on the use of MPC4/IOC4T

card pairs in general, refer to the

VM600 machinery protection system (MPS)

hardware manual and the VM600 MPSx software

manuals. For information on the use of

MPC4/IOC4T card pairs in functional safety

contexts, refer to the refer to the VM600

functional safety manual.

For specific applications, contact your local

Meggitt representative.

Dynamic signal inputs

Filtering : Filtered for protection against electromagnetic interference

(conforms to EC standards).

Refer to the VM600 MPC4 machinery protection card data sheet

for further information.

Buffered dynamic signal outputs

Filtering : Filtered for protection against electromagnetic interference

(conforms to EC standards).

Refer to the VM600 MPC4 machinery protection card data sheet

for further information.

Speed/phase reference inputs

Filtering : Filtered for protection against electromagnetic interference

(conforms to EC standards).

Refer to the VM600 MPC4 machinery protection card data sheet

for further information.

Discrete signal interface (DSI) inputs

Control signal

• Alarm reset (AR) : A closed contact between the DSI AR and DSI RET inputs resets

(clears) the alarms latched by the MPC4/IOC4T card pair.

Note: The alarm reset input (DSI AR) is edge-sensitive and a high-tolow transition is required to activate the reset.

• Danger bypass (DB) : A closed contact between the DSI DB and DSI RET inputs inhibits

(bypasses) the danger relay outputs

• Trip multiply (TM) : A closed contact between the DSI TM and DSI RET inputs multiplies

the alarm levels by a scale factor (software configurable), to

enable adaptive monitoring.

Operating principle : Detection of an open circuit or a closed circuit on the input

Alarm outputs

Alarm relays : 4 per IOC4T card.

The MPC4 card can drive the four local relays on the IOC4T card,

as well the relays on RLC16 relay cards and/or IRC4 intelligent relay

cards using the VM600 rack’s Raw bus or Open Collector (OC) bus.

For IOC4T card relay features, see Relay characteristics on page 4.

For further information on RLC16 or IRC4 relay cards, refer to the

corresponding data sheet.

Note: In a VM600 rack (ABE4x), the Open Collector (OC) bus and/or Raw bus can be used to connect up to

32 outputs from an MPC4/IOC4T card pair to RLC16 relay cards or IRC4 intelligent relay cards in the same rack,

if additional relays are required.

Analog (DC) outputs

Number of outputs : 4 per IOC4T card (one per MPC4 dynamic signal channel)

Signal range : Current output (4 to 20 mA) or voltage output (0 to 10 V),

individually selectable by a jumper on the IOC4T for each output.

Note: For current outputs, the analog output is actually driven in a

slightly wider 2 to 23 mA range, proportional to the input signal.

Accuracy : ≤±1.5%

Linearity error : ≤±0.5%

Admissible load on output : >100 kΩ for voltage output.

<325 Ω for current output.

Relay characteristics

Relay names : RL1 to RL4

Type : PE014005

Contact arrangement : 1 x NC or 1 x NO contact per relay (user configurable).

The selected contacts are available on J2.

Nominal rated voltage : 250 VAC

Nominal rated current : 5 AAC

Maximum breaking capacity

(without contact protection)

: 1250 VA

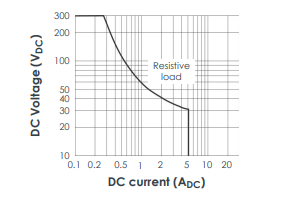

Maximum DC load breaking capacity curve

Operate / release / bounce time : Typically 8 / 8 / 6 ms

Dielectric strength test voltages

• Between open contacts : 1000 VAC

• Between contact and coil : 4000 VAC

Mechanical life : 15 x 106 operations

Electrical life : >105 operations

When used in a VM600 slimline rack (ABE056) with a DC power supply, the relay contacts on an IOC4T card

have a maximum switching voltage of 70 VDC / 33 VAC (RMS) (46.7 VAC (PEAK)

Environmental

Temperature

• Operating : −25 to 65°C (−13 to 149°F)

• Storage : −40 to 85°C (−40 to 185°F)

Humidity

• Operating : 0 to 90% non-condensing

• Storage : 0 to 95% non-condensing

Approvals

Conformity : CE marking, European Union (EU) declaration of conformity.

EAC marking, Eurasian Customs Union (EACU) certificate /

declaration of conformity.

Electromagnetic compatibility : EN 50081-2 and EN 50082-2.

IEC/EN 61000-6-2 and IEC/EN 61000-6-4.

TR CU 020/2011.

Electrical safety : IEC/EN 61010-1.

TR CU 004/2011.

Vibration : IEC 60255-21-1 (Class 2)

Insulation coordination for measuring

relays and protection equipment

: Separate circuits according to IEC 60255-5

for the “separate circuits” version of the IOC4T

Safety integrity level : SIL 1 according to IEC 61508

Environmental management : RoHS compliant

Russian federal agency for technical

regulation and metrology (Rosstandart)

: Pattern approval certificate CH.C.28.004.A N° 60224

Communications

MPC4 to IOC4T bus : Similar to industry pack (IP)

Configuration

MPC4/IOC4T card pair : Software configurable via an RS-232 or Ethernet connection, using

a computer running the VM600 MPSx software.

Hardware configurable using jumpers on the MPC4/IOC4T card

pair.

Note: Configuration via an Ethernet connection requires a CPUx card acting as a rack controller in the VM600

rack.

Status indicators (LEDs)

SLOT ERROR : Used to indicate indicates whether the IOC4T is installed in the

correct slot of the VM600 rack

Power supply to card (input)

Power source : VM600 rack power supply

Supply voltages : +5 VDC and ±12 VDC

Consumption from +5 VDC supply : 1.5 W

Consumption from ±12 VDC supply : 0.7 W, plus an additional 0.25 W per current output used

S

Connectors

J1 : 16-contact screw-terminal connector.

Inputs (analog signals) for dynamic measurement channels 1 to 4.

J2 : 16-contact screw-terminal connector.

Inputs (analog signals) for tachometer (speed) channels 1 to 2.

Outputs (contacts) for relays RL1 to RL4.

J3 : 16-contact screw-terminal connector.

Outputs (analog signals) for DC outputs 1 to 4.

Inputs (digital signals) for DSI control signals: AR, DB and TM.

Outputs (analog signals) for buffered “raw” sensor outputs for

dynamic measurement channels 1 to 4.

Physical

Height : 6U (262 mm, 10.3 in)

Width : 20 mm (0.8 in)

Depth : 125 mm (4.9 in)

Weight : 0.25 kg (0.55 lb) approx.

ORDERING INFORMATION

To order please specify

Type Designation Ordering number (PNR)

IOC4T Different versions of the input/output card (for the MPC4):

– Standard 200-560-000-1Hh

– Separate circuits 200-560-000-2Hh

Notes

Versions of the IOC4T card are available with a conformal coating (“varnish”) applied to the circuitry of the card for additional

environmental protection against chemicals, dust, moisture and temperature extremes.

In 2017, the MPC4 / IOC4T machinery protection card pairs were improved to (1) be RoHS compliant and (2) provide a reduced

buffered dynamic signal output impedance, which required a redesign of the underlying buffered “raw” dynamic signal output

circuitry. Accordingly, the different versions of the MPC4/IOC4T machinery protection card pairs in use are:

• Later versions of the MPC4 (PNRs 200-510-SSS-115, 200-510-SSS-214 and 200-510-SSS-313 or later) and

IOC4T (PNR 200-560-000-114 and 200-560-000-212 or later), which are RoHS compliant and have an output impedance of 50 Ω.

• Earlier versions of the IOC4T (PNRs 200-510-SSS-114, 200-510-SSS-213 and 200-510-SSS-312 or earlier) and

IOC4T (PNR 200-560-000-113 and 200-560-000-211 or earlier), which are not RoHS compliant and have an output impedance of

2000 Ω.

“SSS” represents the firmware (embedded software) version and “Hh” the hardware version. “H” increments are for major

modifications that can affect product interchangeability. “h” increments are for minor modifications that have no effect on

interchangeability.

Meggitt (Meggitt PLC) is a leading international engineering company, headquartered in England, that designs and delivers high-performance

components and subsystems for aerospace, defence and selected energy markets. Meggitt comprises four customer-aligned divisions:

Airframe Systems, Engine Systems, Energy & Equipment and Services & Support.

The Energy & Equipment division includes the Energy Sensing and Controls product group that specialises in sensing and monitoring solutions for a

broad range of energy infrastructure, and control valves for industrial gas turbines, primarily for the Power Generation, Oil & Gas and Services markets.

Energy & Equipment is headquartered in Switzerland (Meggitt SA) and incorporates the Vibro-Meter® product line, which has over 65 years of sensor

and systems expertise and is trusted by original equipment manufacturers (OEMs) globally.

All information in this document, such as descriptions, specifications, drawings, recommendations and other statements, is believed to be

reliable and is stated in good faith as being approximately correct, but is not binding on Meggitt (Meggitt SA) unless expressly agreed in

writing. Before acquiring and/or using this product, you must evaluate it and determine if it is suitable for your intended application. You

should also check our website at www.meggittsensing.com/energy for any updates to data sheets, certificates, product drawings, user

manuals, service bulletins and/or other instructions affecting the product.

Unless otherwise expressly agreed in writing with Meggitt SA, you assume all risks and liability associated with use of the product. Any

recommendations and advice given without charge, whilst given in good faith, are not binding on Meggitt SA. Meggitt (Meggitt SA) takes

no responsibility for any statements related to the product which are not contained in a current Meggitt SA publication, nor for any

statements contained in extracts, summaries, translations or any other documents not authored and produced by Meggitt SA.

The certifications and warranties applicable to the products supplied by Meggitt SA are valid only for new products purchased directly from

Meggitt SA or from an authorised distributor of Meggitt SA.

In this publication, a dot (.) is used as the decimal separator and thousands are separated by thin spaces. Example: 12345.67890.

Copyright© 2019 Meggitt SA. All rights reserved. The information contained in this document is subject to change without prior notice.

Sales offices Local representative Head office

Meggitt has offices in more than

30 countries. For a complete list,

please visit our website.

Meggitt SA

Rte de Moncor 4

PO Box 1616

CH-1701 Fribourg

Switzerland

Tel: +41 26 407 11 11

Fax: +41 26 407 13 01

energy@ch.meggitt.com

www.meggittsensing.com/energy

www.meggitt.com

Document reference DS 268-071

Version 9 – 06.01.2020

DATA SHEET

VM600 IOC4T input/output card

7 / 7

R