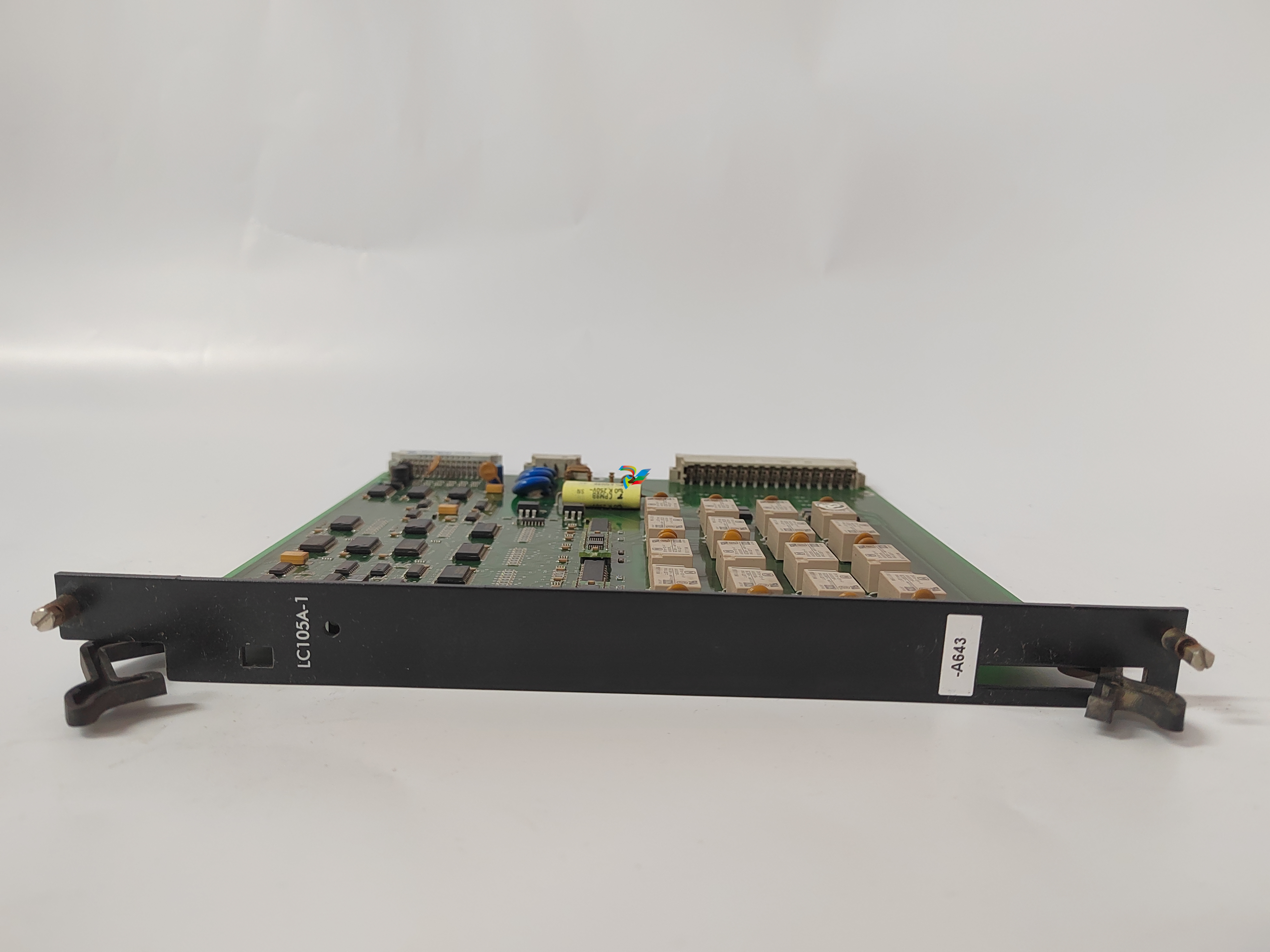

ALSTOM LC105A-2 - 053013582 - 80801764 - C0201900 - C259/267

The ALSTOM LC105A-2 is a robust and high-performance automation device designed to meet the stringent demands of the power industry, petrochemical plants, and general automation applications. Engineered with precision and durability in mind, the LC105A-2 offers exceptional input/output capacity, optimized for complex control systems requiring fast, reliable responses and extensive interfacing capabilities.

Key technical features of the ALSTOM LC105A-2 include its advanced digital input/output modules, supporting up to 128 discrete inputs and 96 outputs, which enable seamless integration with a wide array of sensors, actuators, and control elements. This model boasts a ruggedized design that ensures durability under harsh industrial environments, withstanding temperature fluctuations from -20°C to +70°C and offering high resistance to vibration and electromagnetic interference. Performance-wise, the LC105A-2 delivers rapid processing speeds with a cycle time of less than 1 ms, ensuring real-time control and monitoring that is critical in power generation and petrochemical operations.

In terms of connectivity, the LC105A-2 supports multiple communication protocols, including Modbus, Profibus, and Ethernet/IP, providing versatile integration with existing SCADA and DCS systems. Its modular architecture allows for scalable expansion, making it suitable for both small-scale automation setups and extensive industrial networks. Additionally, the device features comprehensive diagnostic functions and fault detection capabilities, which greatly reduce downtime and maintenance costs.

The application of the LC105A-2 in the power industry is particularly noteworthy. It excels in controlling turbine governors, generator excitation systems, and balance-of-plant equipment due to its precise control algorithms and high reliability. In petrochemical plants, the LC105A-2 manages critical processes such as temperature regulation, pressure control, and safety interlocks, where failure is not an option. For general automation, this model provides a flexible platform capable of automating conveyor systems, packaging lines, and other manufacturing processes with the accuracy and speed demanded by modern industry.

When compared to other ALSTOM automation products, the LC105A-2 stands out for its balance of input/output density, ruggedness, and communication versatility. For instance, while the ALSTOM Micom P430 is well-known for protection relay functions, it does not offer the same level of input/output integration or real-time control capabilities as the LC105A-2. Similarly, the ALSTOM PS421 series focuses more on power system automation but lacks the modular flexibility that the LC105A-2 provides for various industrial automation tasks. The ALSTOM MVS3000-4011, a powerful control system, excels in high-end applications but may be over-specified and cost-prohibitive for medium-sized automation projects where the LC105A-2 provides a more cost-effective yet reliable solution.

Alongside the ALSTOM LC105A-2, we also offer complementary models such as the ALSTOM Blue Line (16), known for its robust motor control capabilities, and the ALSTOM 556421, which serves as an efficient interface module in distributed control systems. The ALSTOM Drives 28x3548 range pairs well with the LC105A-2, offering variable speed drive solutions that enhance energy efficiency in industrial processes. For applications requiring advanced process monitoring, the ALSTOM 20X4478/1081 provides superior data acquisition features. The ALSTOM Villeurbanne N895605527E enhances communication reliability in networked environments, while the ALSTOM 51195-027-01 offers specialized control for turbine operations. The ALSTOM MAE 00-14 and ALSTOM P-1082 models serve as excellent backups or supplementary control units in automated systems, ensuring redundancy and system integrity. Finally, the ALSTOM 31v6900 / 10 is ideal for auxiliary control functions, rounding out a comprehensive automation portfolio when used in conjunction with the LC105A-2.

In summary, the ALSTOM LC105A-2 is a versatile and reliable automation product that excels across power industry, petrochemical, and general automation applications. Its superior input/output capacity, rugged design, and fast processing make it a top choice for engineers seeking dependable control solutions. By integrating the LC105A-2 with other ALSTOM automation products like the Micom P430, PS421, and Blue Line (16), users can build sophisticated, scalable, and highly efficient control systems tailored to their specific industrial needs.

Keywords: ALSTOM LC105A-2, ALSTOM automation products, application of LC105A-2 in power industry, petrochemical, and general automation

| User name | Member Level | Quantity | Specification | Purchase Date |

|---|