GE 531X303MCPBBG1 - AC Power Supply Board for Industrial Applications

The GE 531X303MCPBBG1 stands out as a robust and versatile automation module designed specifically for high-demand applications within the power industry, petrochemical sector, and general automation environments. Engineered with precision, this model offers exceptional input/output capacity, durability, and performance metrics tailored to meet the rigorous operational standards of industrial automation systems.

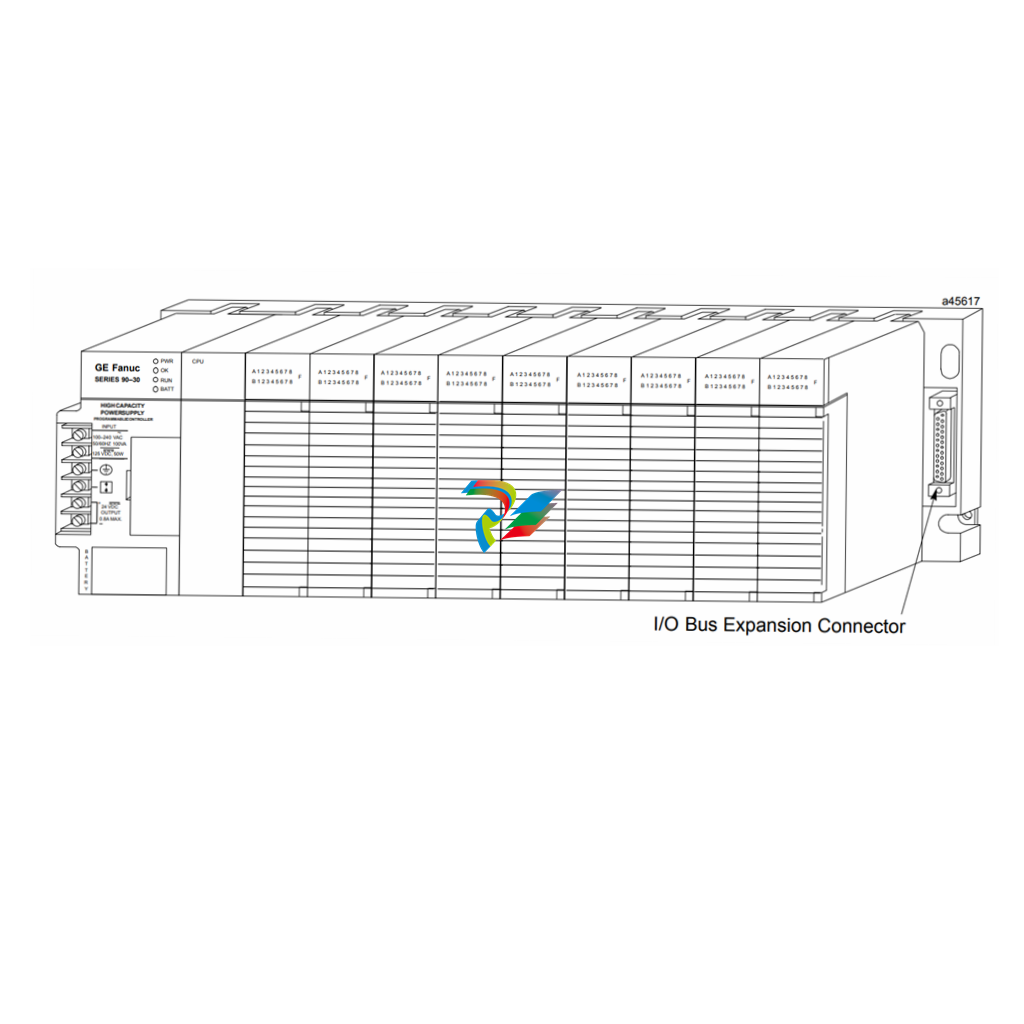

One of the defining features of the GE 531X303MCPBBG1 is its impressive I/O handling capability, supporting a wide range of input and output signals essential for complex control processes. Its high-density design ensures reliable communication between interconnected systems, facilitating seamless data transfer crucial for real-time monitoring and control. Built with industrial-grade components, it boasts enhanced durability and resistance to harsh environments, including extreme temperatures, vibrations, and electrical noise—making it ideal for deployment in demanding settings such as power substations, petrochemical refineries, and automated manufacturing lines.

Performance-wise, the GE 531X303MCPBBG1 is engineered for stability and longevity, with a proven track record of maintaining operational integrity over extended periods. Its fast processing speeds and low latency support precise control operations, which are vital for maintaining safety and efficiency in critical infrastructure. Additionally, the module's compatibility with a broad range of GE automation products ensures easy integration into existing systems, enabling operators to scale and upgrade their automation architecture without extensive rewiring or reconfiguration.

In real-world applications, the GE 531X303MCPBBG1 excels in scenarios requiring high reliability and complex data management. For instance, in power generation plants, it manages real-time data from multiple sensors, optimizing grid stability and power distribution. In petrochemical facilities, it controls intricate process sequences, ensuring safe and efficient operation under volatile conditions. Its resilience and high performance also make it suitable for general automation tasks such as manufacturing process control, instrumentation, and safety system management.

When compared with other models within the GE portfolio, the 531X303MCPBBG1 offers distinct advantages. Unlike models such as GE DS3800HDDA or GE IC200ALG620, which focus on specific control functions, the 531X303MCPBBG1 provides a comprehensive I/O solution with enhanced environmental robustness. It also surpasses models like GE 353A4F1CNB4 in terms of processing speed and environmental resilience. Alongside models like GE 8607ERL and GE SR750-P5-G5-S5-HI-A20-R-E, the 531X303MCPBBG1 forms part of a cohesive automation ecosystem, facilitating complex control schemes with streamlined integration.

Moreover, for applications requiring advanced control and communication, the GE IC200ALG264E or GE IC693MDL655 can complement the 531X303MCPBBG1, offering specialized functions such as programmable logic control and network interfacing. The GE DS200PCTMG1AAA provides additional data processing capabilities, enhancing overall system robustness. For comprehensive automation solutions, models like GE IS200HSLAH2ADE and GE IC695ACC412 serve as complementary controllers, expanding operational flexibility.

In conclusion, the GE 531X303MCPBBG1 is a cornerstone component in GE's automation product lineup, delivering high input/output capacity, exceptional durability, and reliable performance in critical industrial environments. Its application of 531X303MCPBBG1 in power industry, petrochemical, and general automation underscores its versatility and importance for modern industrial operations. When paired with other trusted GE models such as the GE 750-P5-G5-S5-HI-A20-R-E, GE DS3800HDDA, or GE IS200TREAH2AED, it ensures a comprehensive, scalable, and resilient automation system capable of meeting the toughest industrial challenges.

| User name | Member Level | Quantity | Specification | Purchase Date |

|---|