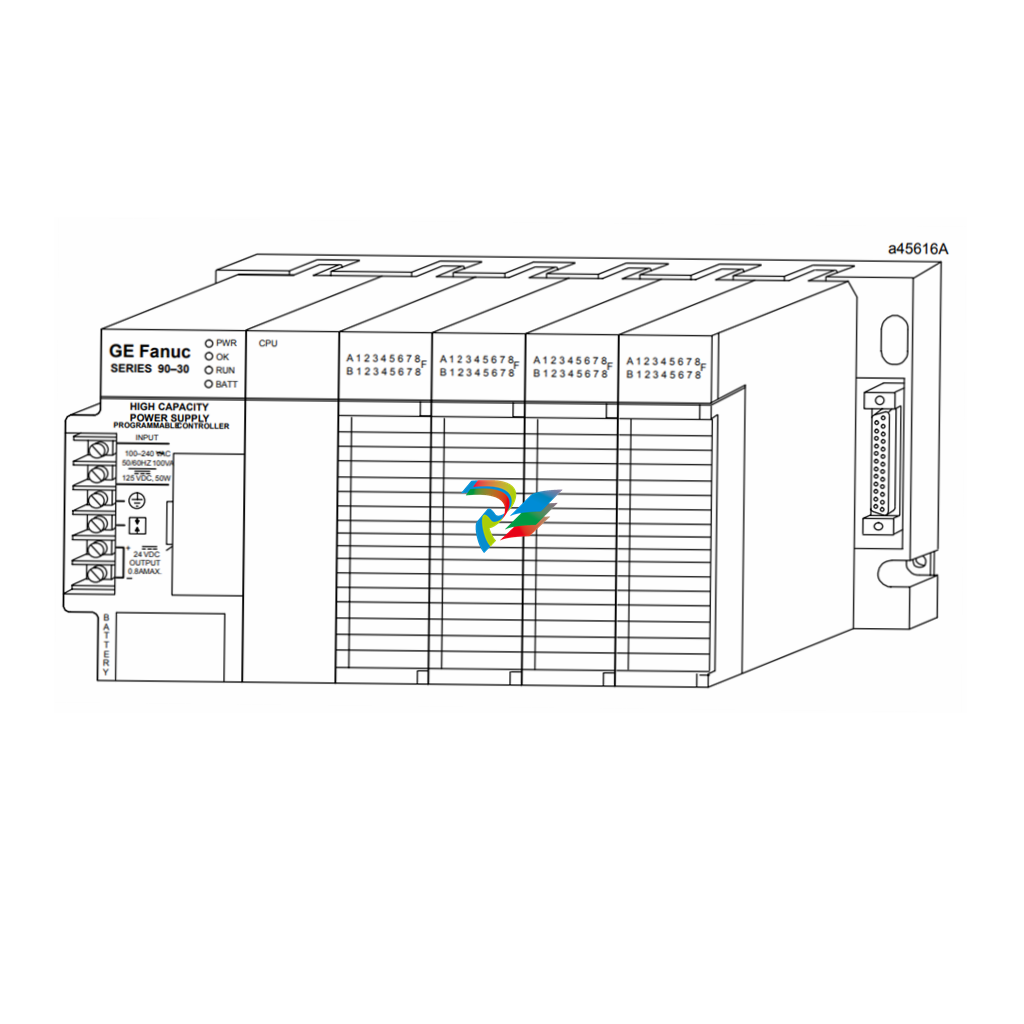

GE H201TI - High-Performance Industrial Control Module

The GE H201TI stands out as a robust and versatile component within GE’s extensive lineup of automation products, specifically engineered to meet the demanding needs of power industry, petrochemical, and general automation applications. Offering high input/output capacity combined with exceptional durability, the H201TI ensures reliable performance even in the most challenging operational environments. Its sophisticated design incorporates advanced performance metrics, making it an ideal choice for complex control and automation tasks.

One of the key technical features of the GE H201TI is its extensive input/output (I/O) capabilities, which facilitate seamless integration with various industrial control systems. The module supports a significant number of digital and analog I/O points, enabling efficient data acquisition and control across sprawling automation networks. Its high-speed processing ensures real-time responsiveness, critical in applications such as power plant control, refinery automation, or large-scale manufacturing processes. Moreover, the H201TI is built with ruggedized components that withstand harsh environmental conditions, including extreme temperatures, vibration, and electrical noise, ensuring long-term operational stability.

Durability is a hallmark of the GE H201TI, which is designed to deliver continuous performance over prolonged periods without degradation. The module features enhanced thermal management and protective circuitry, reducing the risk of failure due to electrical surges or thermal stress. Its reliability is further supported by GE’s rigorous testing standards, making it suitable for critical applications where downtime can be costly. The H201TI also offers flexible configuration options, allowing integration into various control architectures, whether as part of a modular system or standalone deployment.

In real-world scenarios, the application of the H201TI in the power industry is evident through its deployment in turbine control systems, boiler management, and substation automation. Its ability to handle high I/O loads makes it indispensable for petrochemical plants, where precise control of process variables is crucial for safety and efficiency. Additionally, in general automation settings such as manufacturing lines and material handling systems, the H201TI ensures smooth and coordinated operations, reducing latency and enhancing productivity.

Compared to other models within GE’s automation portfolio, the H201TI offers a distinct advantage through its combination of high I/O capacity and rugged design, making it particularly suitable for large-scale and demanding environments. For instance, models like the GE IC200ALG430 and GE IS220PTURH1AD provide specialized functions, but the H201TI’s broad I/O support and robustness make it a versatile centerpiece for complex control systems. Alongside models such as GE DS200VPBLG1AEE and GE Multilin/489, which cater to protection and power management, the H201TI complements these by delivering reliable control interface capabilities.

Other related models, including GE V7768-320000 and GE IC693ALG220G, align with H201TI's application scope by enhancing system integration and scalability. For example, the GE A06B-6107-H004 offers precise motion control, while the GE IS200TRPAS1AFD and GE DS200TCPSG1 extend system versatility in automation tasks. The GE IC660EBA024 and GE DS3800NOAA1F1D provide additional protective functions, ensuring comprehensive system safety when used in conjunction with the H201TI. Furthermore, models like GE DS200SHVIG1B and GE 12HFA51A42H contribute to high-performance control and monitoring, establishing a cohesive and reliable automation ecosystem.

In summary, the GE H201TI embodies a high-performance, durable, and flexible solution for critical industrial control applications. Its extensive I/O capacity, rugged construction, and compatibility with a wide array of GE automation products—including the GE IC200ALG430, GE DS200VPBLG1AEE, GE Multilin/489, GE V7768-320000, GE IC693ALG220G, GE A06B-6107-H004, GE IS200TRPAS1AFD, GE DS200TCPSG1, GE IS220PDIAH1A, and GE PCH1026—make it a cornerstone component in modern automation systems. Leveraging the application of H201TI in power industry, petrochemical, and general automation enhances operational efficiency, safety, and system longevity, reaffirming GE’s commitment to delivering innovative and reliable automation products tailored to industry needs.

| User name | Member Level | Quantity | Specification | Purchase Date |

|---|