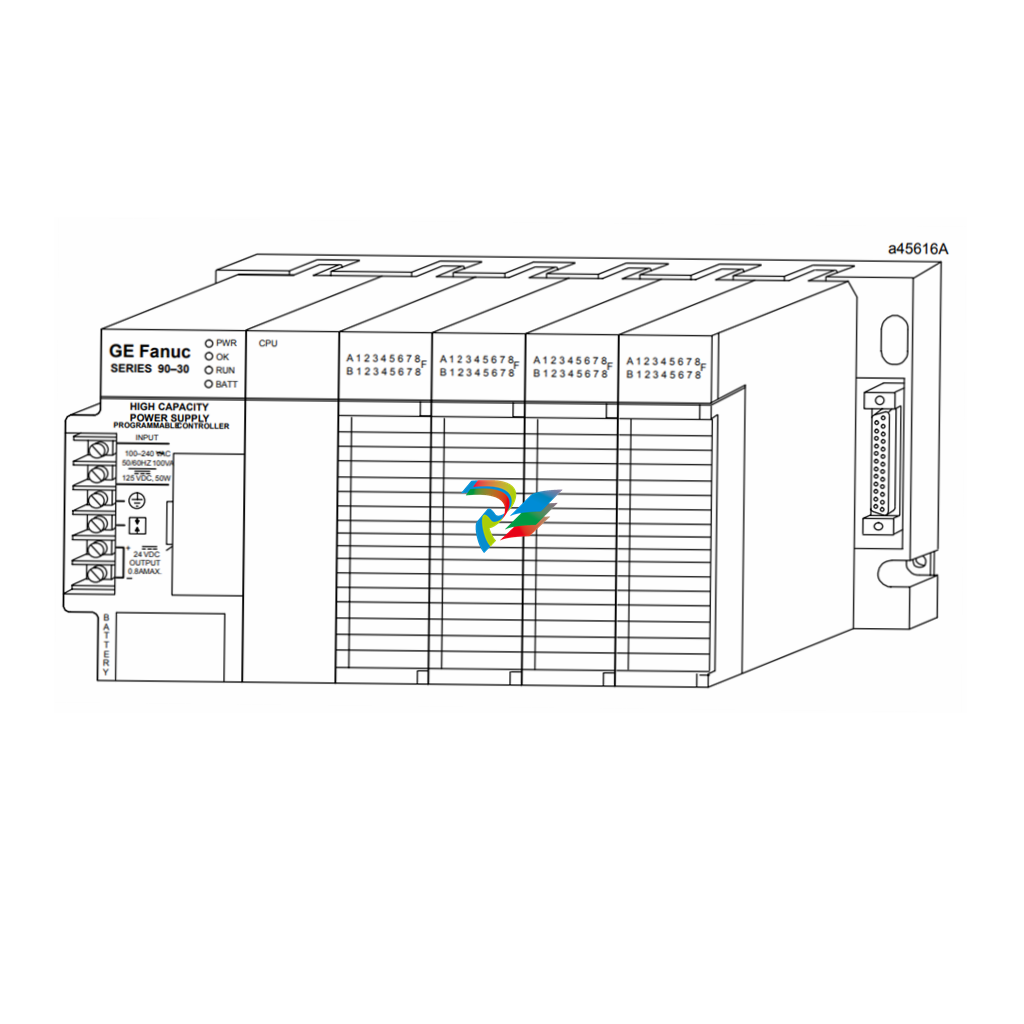

GE IC693BEM331K - Industrial Controller

The GE IC693BEM331K is a highly versatile and robust I/O module designed to meet the demanding needs of modern industrial automation systems. Engineered by GE, a leader in industrial automation products, this model offers exceptional performance tailored for applications across the power industry, petrochemical sector, and general automation environments. Its unique combination of high input/output capacity, durability, and precision makes it an ideal choice for complex control systems requiring reliable data acquisition and signal management.

At its core, the GE IC693BEM331K provides a substantial number of digital and analog I/O channels, enabling seamless integration with a wide array of sensors, actuators, and control devices. This module typically supports multiple channels, ensuring comprehensive coverage of process variables in large-scale automation setups. Its robust design ensures long-term durability, withstanding harsh industrial conditions such as temperature fluctuations, vibration, and electrical noise—characteristics critical for power plants, chemical processing facilities, and manufacturing plants. The module’s performance metrics include rapid response times and high signal integrity, ensuring accurate data transfer and real-time control, which are vital for maintaining operational efficiency and safety.

In real-world usage scenarios, the GE IC693BEM331K excels in environments demanding high reliability and precision. For example, in the power industry, it can be integrated into control systems managing electricity generation and distribution, providing real-time monitoring of electrical parameters and facilitating smooth grid operation. In petrochemical plants, it plays a crucial role in process automation, controlling complex chemical reactions and ensuring safety by providing accurate feedback from various sensors. Similarly, in general automation, it supports assembly lines, packaging, and material handling systems, where quick response and dependable data exchange are essential for maintaining productivity.

Compared to other models within GE’s extensive portfolio, such as the GE IC695CPU315 or the GE IC200CHS002M, the IC693BEM331K stands out due to its specific focus on I/O capacity and ruggedness, making it particularly suitable for high-channel-count applications. While models like the GE DS200SLCCG1ACC or GE IS200YDOAS1B excel in different control functions, the IC693BEM331K offers a balanced solution for expanding I/O requirements without compromising durability or response times. Its compatibility with a variety of GE automation products, such as the GE ES5DP33 or the GE SR750-P5-G5-S5-HI-A20-R, enables integrated system design and streamlined maintenance.

Other related models like the GE IC697CHS790D and GE IC660BBD025 complement the IC693BEM331K by offering specialized control or communication capabilities, providing a comprehensive ecosystem for industrial automation. The GE DS200IQXSG1AAA and GE IS230SRLYH2A can be employed alongside to extend system flexibility, while models such as the GE IC200PNS002 facilitate networked control solutions. These models collectively support a wide range of automation tasks, from process control to safety management.

In summary, the GE IC693BEM331K stands as a cornerstone of GE’s automation products, offering high I/O density, durability, and performance for applications in power generation, chemical processing, and manufacturing. Its integration capability with models like the GE WES5123-1200 or the GE DS3820AIQA ensures comprehensive automation solutions tailored to industry demands. For engineers and system integrators seeking reliable, high-performance I/O modules, the application of IC693BEM331K in power industry, petrochemical, and general automation environments underscores its value as a trusted component in complex control architectures.

| User name | Member Level | Quantity | Specification | Purchase Date |

|---|