Your definitive source for quality pre-owned equipment

engineers derived the optimal fin thickness and spacing using

a specially designed computational fluid dynamics (CFD)

model.

Finned Motors - Designed for Horizontal

and Vertical Orientation

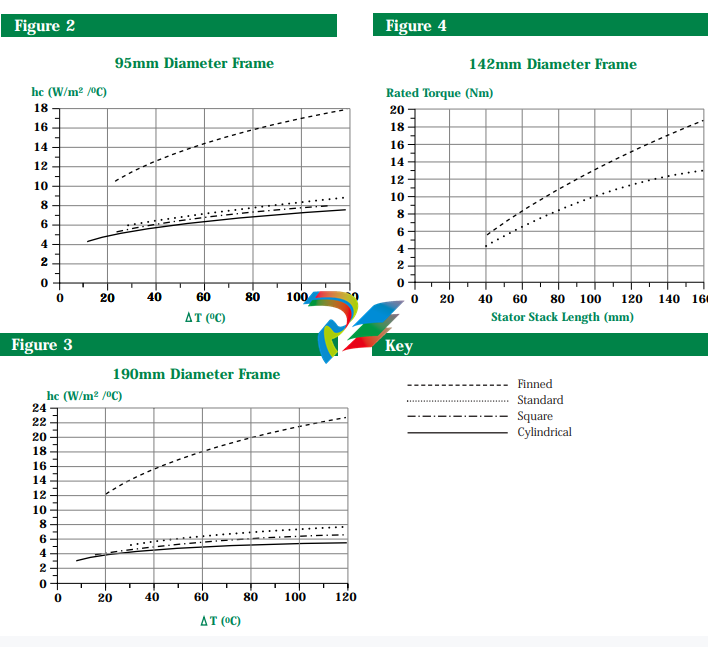

Figures 2 and 3 show charts comparing the variation between

hC (heat transfer coefficient for convection) with ∆T for the

finned motor design against traditional types. The heat

transfer coefficient shows a massive 100% to 200%

improvement over conventional housings.

Figure 4 compares the rated torque of a range of motors with

and without radial finning. The figure takes account of the

effect of any additional conductive cooling through the front

flange and radiation. The additional convection cooling gives

a sizeable increase in torque for the finned motor range.

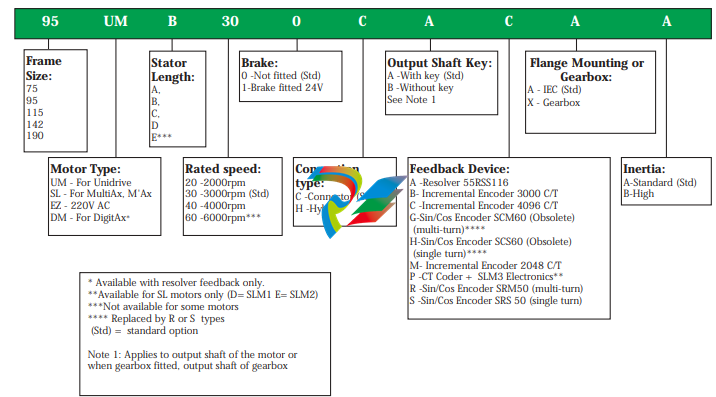

Ordering Information

Use the information given in the illustration below to create

an order code for the Unimotor. The details in the green

band are an example of an order code. CT Dynamics

recommends that you order the required mating connectors

at the time of placing your order. For further details turn to the

cables. See also the grid overleaf, which gives standard and

optional features available for each motor. If you are unsure

which motor you need see ‘Selecting the Correct Motor’.