Your definitive source for quality pre-owned equipment

Full-service, independent repair center

with experienced engineers and technicians on staff.

We buy your excess, underutilized, and idle equipment

along with credit for buybacks and trade-ins.

Custom engineering

so your equipment works exactly as you specify.

• Critical and expedited services • Leasing / Rentals/ Demos

• In stock/ Ready-to-ship • !TAR-certified secure asset solutions

Control Techniques Dynamics Limited

CT Dynamics is a British company renowned for its

innovations in the industrial servo, aerospace and defence

markets. Founded some 40 years ago it has developed a

leading position by combining two of the UK’s best servo

companies: Moore Reed and the Powerotor Division of

Evershed and Vignoles. CT Dynamics’ experience in the field

of servo and rotating components provides a strong base

from which to develop cost effective solutions for a spectrum

of applications from machine tools, mechanical handling,

pick and place machinery - through to specialised

mechanisms and actuators for the avionics industry.

CT Dynamics is a member of the Emerson group of the USA.

This gives the company access to a vast engineering design

resource in the USA, in the UK and in mainland Europe. As a

result CT Dynamics offers continuous advances in product

range, backed with the expertise and flexibility to meet the

demands of your applications - now and in the future.

Introduction

The Unimotor range has been developed following extensive

research and testing of thermal dynamic theories and

practices.

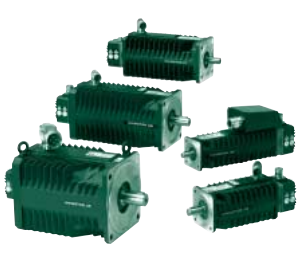

This range is available in five frame sizes 75; 95; 115; 142

and 190mm, in a unique and instantly recognisable finned

design that offers extra strength, rigidity and thermal

performance. These are important features for high

performance servo systems.

Designed to operate from switched-mode three-phase AC

drive outputs with DC link volts up to 750V DC, this range

employs a registered UL approved insulation system.

There are four basic motor types, each for different drives.

UM, SL and DM motors are for 400/440V nominal AC

drive supply voltage.

EZ motors have identical mechanical construction and

feedback options, but support a different winding to suit

220V nominal AC drives such as Unidrive LV and Epsilon /EN

drives.

UM, SL and DM Motors

UM Motor

The UM motor has been primarily designed to operate with

the Unidrive and Unidrive SP, but can be used with any

suitable drive.

Feedback options include resolver; or incremental, sincos

single-turn, sincos multi-turn optical encoders.

SL Motor

The SL version is a UM motor fitted with special SLM

technology electronic feedback that operates with Control

Techniques’ M’Ax and MultiAx drives. This motor-drive

combination offers extremely high resolution, for superb

system speed control. High resolution is essential for many

system applications where speed and position errors must be

miniscule.

The feedback comprises of a special Sincos encoder and SLM

electronics, both contained within the standard UM outline.

The encoder has a memory programmed with all the

essential motor characteristics necessary to automatically set

all M’Ax parameters, giving an instant ‘Plug and Play’

capability

DM Motor

The DM motor is suitable for use with the DigitAx drive. The

stator connections to U and V are interchanged to match the

DigitAx.

Accessories

Other options

Gearboxes - motor torque can be extended by a good

selection of factory-fitted gearboxes, available to order in a

wide variety of options.

Forced air-cooling - customer-fitted fan blown boxes

specially designed to fit the range of motors, can directly

enhance motor performance. (Not suitable for SL).

Custom specials - a range of special adaptations e.g. shaft

or feedback type are already designed and may be available

where quantities justify.

Cable assemblies - ready made power and signal cables in

lengths of 2-100 metres to connect motors to the

appropriate drive

Heat Transfer from Radially

Finned Motor Housings

One of the most important features of an electric motor is its

rated torque value per unit of motor volume. To maximise this

value, the motor surface must lose heat as efficiently as

possible. Additionally, servo motors must provide full torque

at zero speed. It is not practical to use a shaft mounted fan for

cooling so the motor must keep cool through a combination of

natural convection, conduction through the front flange, and

radiation.

Figure 1. Naturally ventilated motors usually have a relatively smooth

frame surface. The frame is cylindrical or square, or a combination of the

two. The above illustrations show half cross sections of the various motor

types as used in the CFD model

Adding fins to a surface increases the convective cooling -

radiators are an everyday example. Axial fins are common in

forced ventilated motors. CT Dynamics has taken this concept

a stage further to develop the Unimotor range of servo motors.

For a motor to give a performance that requires minimal derating, it must be designed so that it can be mounted in a

number of orientations. The Unimotor’s finned design ensures

that the motors can be mounted horizontally or vertically

without significant effect on heat transfer. CT Dynamics’