schneiderI/A Series® Hardware Control Processor 40

The Control Processor 40 is a high-end optionally

fault-tolerant station in the Control Processor family

(CP10, CP30, CP40) that has:

• a larger memory capacity to support a greater

number of blocks

• a faster processor for increased block processing

With high performance, the CP40 is both economical

and in line with today's advancing technology. Other

members of the CP family are easily upgradable to

CP40 capabilities.

The Control Processor 40 performs regulatory, logic,

timing, and sequential control together with

connected:

• Fieldbus Modules (FBMs)

• Fieldbus Cluster I/O Cards (FBCs)

• SPECTRUM Migration Integrator I/O

• SPEC 200 Migration Integrator I/O

• SPEC 200 MICRO Migration Integrator I/O

It also performs data acquisition (via the Fieldbus

Modules), alarm detection and notification, and may

optionally serve as an interface for one or more Panel

Display Stations.

The non-fault-tolerant version of the Control

Processor 40 is a single-width processor module. The

fault-tolerant version consists of two single-width

processor modules.

Enhanced Reliability

The Control Processor 40 offers optional faulttolerance for enhanced reliability. The fault-tolerant

control processor configuration consists of two

parallel-operating modules with two separate

connections to the Nodebus and to the Fieldbus.

The two control processor modules, married together

as a fault-tolerant pair, are designed to provide

continued operation of the unit in the event of virtually

any hardware failure occurring within one module of

the pair. Both modules receive and process

information simultaneously, and faults are detected by

the modules themselves. One of the significant

methods of fault detection is comparison of

communication messages at the module external

interfaces. Upon detection of a fault, self-diagnostics

are run by both modules to determine which module

is defective. The non-defective module then assumes

control without affecting normal system operations.

To further ensure reliable communications, the faulttolerant control processor performs error detection

and address verification tests in its Nodebus and

Fieldbus interfaces.

For enhanced reliability during maintenance

operations, the Control Processor 40 is equipped with

a recessed reset button, located at the front of the

module. This feature provides for manually forcing a

module power off and on (reboot) without removing

the module from the enclosure.

Diagnostics

The Control Processor 40 uses three types of

diagnostic tests to detect and/or isolate faults:

• Power-up self-checks

• Run-time and watchdog timer checks

• Off-line diagnostics

Power-up self-checks are self-initiated when power is

applied to the control processor. These checks

perform sequential tests on the various control

processor functional elements. Red and green

indicators at the front of the control processor module

reflect the successful (or non-successful) completion

of the various phases of the control processor startup

sequence.

The run-time and watchdog timer checks provide

continuous monitoring of control processor functions

during normal system operations. The operator is

informed of a malfunction by means of printed or

displayed system messages.

Off-line diagnostics are temporarily loaded into the

system for the purpose of performing comprehensive

tests and checks on various system stations and

devices. Using the off-line diagnostics, a suspected

fault in the control processor can be isolated and/or

confirmed.

Fieldbus Modules

Fieldbus Modules provide connection of digital I/O,

analog I/O, and Intelligent Transmitters to control

processors. There are two types of Fieldbus Modules:

Main and Expansion. Some main modules can be

expanded using an expansion module.

A wide range of Fieldbus Modules is available to

perform the signal conversion necessary to interface

the control processor with field sensors and

actuators. For further information on the Fieldbus

Modules, refer to the Fieldbus Modules Product

Specification Sheet (PSS 21H-3B1 B3).

Fieldbus Flexibility

The Control Processor 40 is used in three different

Fieldbus configurations, which provide broad flexibility

in Fieldbus implementation:

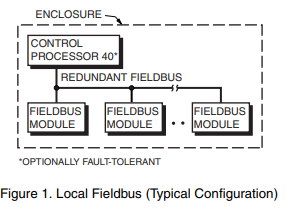

• Local Fieldbus (Figure 1) - Used only within the

enclosure, the local bus can extend up to 10 m

(30 ft). Up to 24 Fieldbus Modules (excluding

expansion modules) attach directly to the local

bus, which is redundant

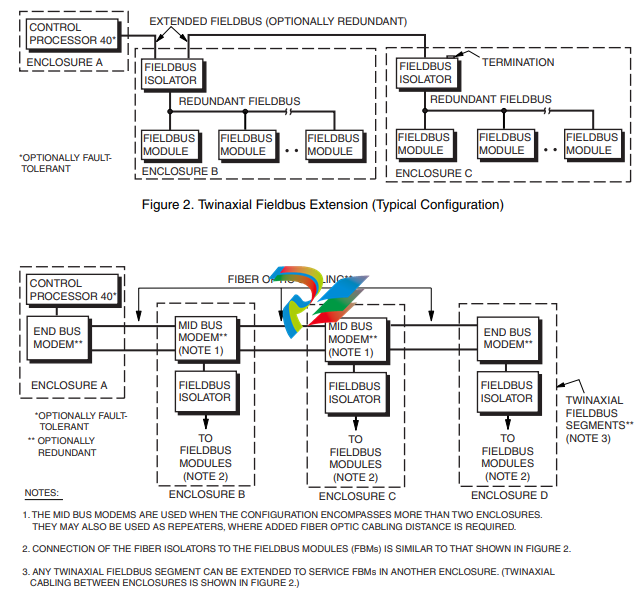

• Twinaxial (Dual-Conductor Coaxial) Fieldbus

Extension (Figure 2) - Using twinaxial cable, the

Fieldbus can optionally extend outside of the

enclosure and can be up to 1800 m (6000 ft) in

length. Up to 64 Fieldbus Modules (excluding

expansion modules) attach to the extended bus

through Fieldbus isolators. (Up to 24 Fieldbus

Modules, excluding expansion modules, can

connect to each isolator.) The twinaxial Fieldbus

extension may be redundant.

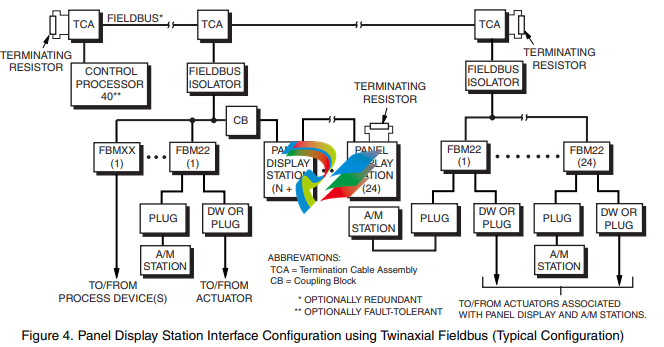

• Fiber Optic Fieldbus Extension (Figure 3) - The

fiber optic Fieldbus can optionally extend the

distance as well as add application versatility and

security. Overall Fieldbus length can be up to

20 km (12.4 mi). Like the twinaxial Fieldbus

configuration, the fiber optic Fieldbus

configuration supports up to 64 Fieldbus Modules

(excluding expansion modules), up to 24

Modules per isolator.

All three Fieldbus configurations use serial data

communication complying with Electronic Industrial

Association (EIA) Standard RS-485. The data

transmission rate is 268.75 Kbps.

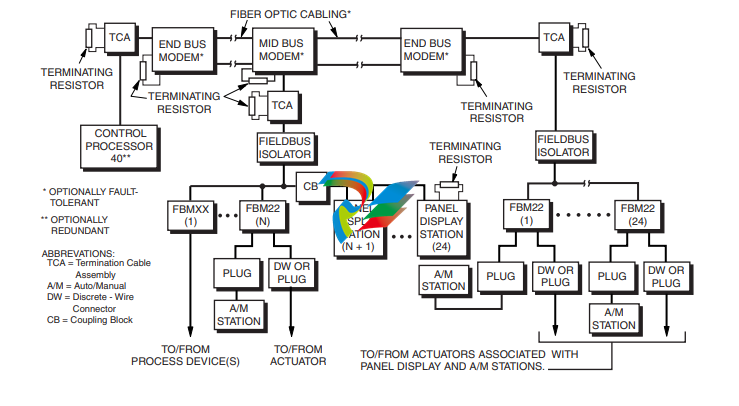

Panel Display Station Interfacing

The Control Processor 40 achieves the capability to

interface Panel Display Stations when the DSI (Panel

Display Station Interface) block is selected via the

configurator. In this capacity, the Control

Processor 40 can interface up to 24 Panel Display

Stations, or a combination of Fieldbus modules

(which may include associated Auto/Manual Stations)

and Panel Display Stations mixed on the same

Fieldbus. (Note, however, that per configuration rules,

one Panel Display Station counts as two Fieldbus

Modules.)

Control strategies should be planned such that all

blocks involved with the Panel Display Station,

Auto/Manual Station, and the control loops being

monitored or controlled are in the same Control

Processor 40, and ideally in the same compound.

The Control Processor 40 connects to the Panel

Display Stations and Fieldbus Modules via either of

two types of Fieldbus communications media:

twinaxial cable or fiber optic cable. Figure 4 shows a

typical twinaxial Fieldbus configuration, and Figure 5

shows a typical fiber optic Fieldbus configuration.

(Refer to Fiber Optic Fieldbus Product Specification

Sheet PSS 21H-7P1 B3 for additional fiber optic

Fieldbus application information.)

Cluster I/O Subsystem Interfacing

The Control Processor 40 interfaces with the Fieldbus

Cluster Input/Output Subsystem that consists of the

Fieldbus, a multi-slot chassis configuration of a

Fieldbus Processor (FBP10), analog/digital Fieldbus

Cards (FBCs), and power supply and power monitor

card. These Cluster I/O subsystems meet the needs

of applications where a high number of channels per

card are required. Figure 6 shows a typical twinaxial

Fieldbus configuration. (Refer to the Fieldbus Cluster

I/O Subsystem PSS 21H-2T1 B3 for additional

information.)

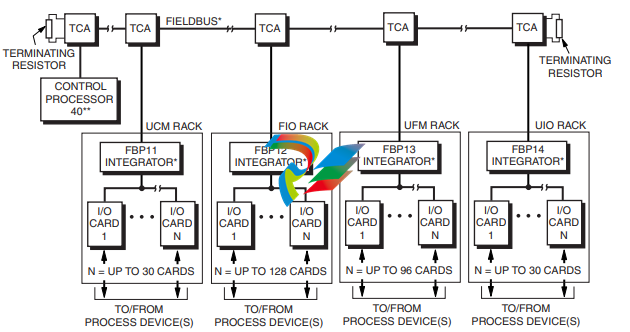

SPECTRUM Migration Interfacing

The Control Processor 40 interfaces with a

SPECTRUM Migration Integrator subsystem via a

single or redundant I/A Series Fieldbus and a

Fieldbus Processor (FBP) with built-in FBP isolator

located within the subsystem. There are four different

FBP integrators to accommodate Unit Control

Modules (UCM), Field Input/Output Units (FIO),

Universal Field Multiplexers (UFM), and Universal

Input/Output Units (UIO).

The CP40 control strategy can include any of

following SPECTRUM configurations:

• a single SPECTRUM Migration Integrator

subsystem

• multiple types of SPECTRUM Migration

Integrator subsystems

• Fieldbus Modules (FBMs) and/or other Fieldbusbased process interface subsystems along with

the SPECTRUM Integrator subsystem(s)

Control is via the software resident in the FBP

Integrator and in the SPECTRUM I/O Equipment

Control Blocks (ECBs) operating at the CP level.

Figure 7 illustrates a typical configuration with

multiple types of Integrator subsystems with nests of

I/O cards. (Refer to PSS 21H-7Q1 B3 SPECTRUM

Migration Integrators for additional information.)

Figure 7. Twinaxial Fieldbus SPECTRUM Migration Subsystem Interface Configuration (Typical Configuration)

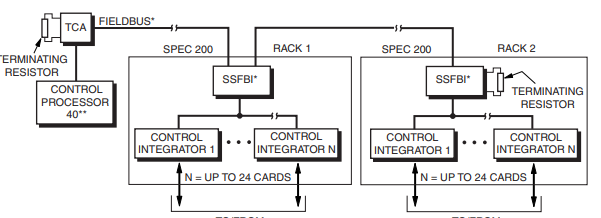

SPEC 200 Control Interfacing

For migration of SPEC 200 control to I/A Series

Systems, the Control Processor 40 interfaces via a

single or redundant I/A Series Fieldbus with the

SPEC 200 Control Integrator subsystem. This

subsystem consists of individual Control Integrators,

and Fieldbus Isolators attached within the SPEC 200

rack.

Control is via the software resident in the Control

Integrator and in the SPEC 200 I/O Equipment

Control Blocks (ECBs) operating at the CP level.

Figure 8 illustrates a typical configuration with

multiple Control Integrators in the SPEC 200

subsystem. (Refer to PSS 21H-7R1 B3 SPEC 200

Control Integrators for additional information.)

Figure 8. Twinaxial Fieldbus SPEC 200 Control Subsystem Interface Configuration (Typical Configuration)

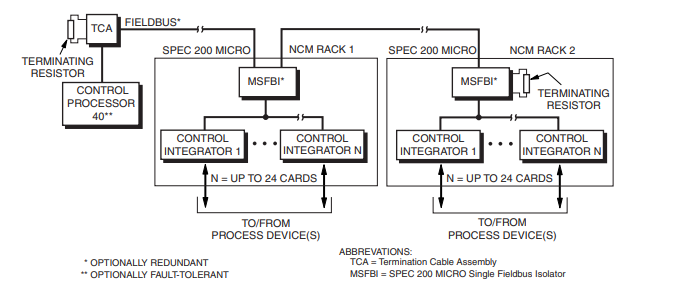

SPEC 200 MICRO Control Interfacing

For migration of SPEC 200 MICRO control to

I/A Series systems, the Control Processor 40

interfaces via a single or redundant I/A Series

Fieldbus with the SPEC 200 MICRO Control

Integrator subsystem. This subsystem consists of

individual Control Integrators, and Fieldbus Isolators

attached within the SPEC 200 MICRO rack (NCM or

SPEC 200 2ANU).

Control is via the software resident in the Control

Integrator and in the SPEC 200 MICRO I/O

Equipment Control Blocks (ECBs) operating at the

CP level. Figure 9 illustrates a typical configuration

with multiple Control Integrators in the SPEC 200

MICRO subsystem. (Refer to PSS 21H-7R2 B3 SPEC

200 MICRO Control Integrators for additional

information.)

Control Processor 40 Upgrade

Upgrading a Control Processor 30, Control Processor

10, Tank Processor 10, or Display Processor 10 to a

CP40 involves:

• Replacing the existing Control Processor with a

CP40

• Upgrading the software license

• Modifying the System Configurator to identify the

CP40

• Loading existing compounds to the CP40

Twinaxial Fieldbus SPEC 200 MICRO Control Subsystem Interface Configuration (Typical Configuration)

Processor Type

CONTROL PROCESSOR

Microprocessor-based Intel 486DX4 (running at

100 MHz) with stored programs, using high-speed

communication capability.

NODEBUS PROCESSOR

82596CA LAN CoProcessor

FIELDBUS PROCESSOR

8344AH MicroController with serial port

Memory

SIZE

4 MB storage

ERROR DETECTION

Parity provides single-bit error detection for each

byte.

Process I/O Communications

LOCAL TWINAXIAL(A) FIELDBUS

Type

EIA RS-485

Distance

10 m (30 ft)

Transmission Rate

268.75 Kbps

EXTENDED TWINAXIAL(A) FIELDBUS(B)

Type

EIA RS-485

Distance

1800 m (6000 ft)

Transmission Rate

268.75 Kbps

FIBER OPTIC FIELDBUS(C)

Type

Optical

Distance

20 km (12.4 mi)

Transmission Rate

268.75 Kbps

Process I/O Capacity

LOCAL

24 Fieldbus Modules(D), maximum

EXTENDED

64 Fieldbus Modules(D), maximum (24 maximum on

any one Fieldbus isolator)

PANEL DISPLAY STATION INTERFACING

Up to 64 FBMs(D) or FBM equivalents (24 maximum

on any one Fieldbus isolator). One Panel Display

Station counts as two FBMs. For example, if 24

FBMs are used, only 20 Panel Display Stations may

be used.

Power Requirements

INPUT VOLTAGE (REDUNDANT VOLTAGE)

39 V dc typical

CONSUMPTION (PER NON-FAULT-TOLERANT

MODULE)

15 W, maximum

Indicators

Red and green light-emitting diodes (LEDs) indicate

operational status.

Internal Diagnostics

Self-checking performed at power-up. Runtime checks

and watchdog timer function performed during

operation.

ENVIRONMENTAL SPECIFICATIONS(A)

Operating

TEMPERATURE

0 to 60°C (32 to 140°F)

RELATIVE HUMIDITY

5 to 95% (Noncondensing)

ALTITUDE

-300 to +3,000 m (-1,000 to +10,000 ft)

Environmental Contamination Level

Class G3 (Harsh) as defined in ISA Standard S71.04

Storage

TEMPERATURE

-40 to +70°C (-40 to +158°F)

RELATIVE HUMIDITY

5 to 95% (Noncondensing)

ALTITUDE

-300 to +12,000 m (-1,000 to +40,000 ft)

PSS 21H-1B3 B3

Page 11

(A) The environmental ranges can be extended by the type of enclosure containing the module. {Refer to the applicable Product

Specification Sheet (PSS) which describes the specific enclosure that is to be used.}

PHYSICAL SPECIFICATIONS

Configuration

Single-width processor module. The fault- tolerant

version consists of two single-width processor

modules with two interconnecting buses (X-bus and

Z-bus).

Mass (Maximum)

1.7 kg (3.75 lb) for a single, non-fault-tolerant module.

Mounting

May be placed in any of the following mounting

structure slots:

– 1 X 8 Mounting Structure

– Industrial Enclosures (IE16 and IE32),

Structural Foam or Metal

– Field Enclosure 8, Structural Foam or Metal

In the fault-tolerant version, the two modules must be

mounted in adjacent mounting structure slots with the

two interconnecting buses.

.png)

.png)

.png)