schneiderI/A Series® Hardware Control Processor 40

The Control Processor 40 is a high-end optionally

fault-tolerant station in the Control Processor family

(CP10, CP30, CP40) that has:

• a larger memory capacity to support a greater

number of blocks

• a faster processor for increased block processing

With high performance, the CP40 is both economical

and in line with today's advancing technology. Other

members of the CP family are easily upgradable to

CP40 capabilities.

The Control Processor 40 performs regulatory, logic,

timing, and sequential control together with

connected:

• Fieldbus Modules (FBMs)

• Fieldbus Cluster I/O Cards (FBCs)

• SPECTRUM Migration Integrator I/O

• SPEC 200 Migration Integrator I/O

• SPEC 200 MICRO Migration Integrator I/O

It also performs data acquisition (via the Fieldbus

Modules), alarm detection and notification, and may

optionally serve as an interface for one or more Panel

Display Stations.

The non-fault-tolerant version of the Control

Processor 40 is a single-width processor module. The

fault-tolerant version consists of two single-width

processor modules.

Enhanced Reliability

The Control Processor 40 offers optional faulttolerance for enhanced reliability. The fault-tolerant

control processor configuration consists of two

parallel-operating modules with two separate

connections to the Nodebus and to the Fieldbus.

The two control processor modules, married together

as a fault-tolerant pair, are designed to provide

continued operation of the unit in the event of virtually

any hardware failure occurring within one module of

the pair. Both modules receive and process

information simultaneously, and faults are detected by

the modules themselves. One of the significant

methods of fault detection is comparison of

communication messages at the module external

interfaces. Upon detection of a fault, self-diagnostics

are run by both modules to determine which module

is defective. The non-defective module then assumes

control without affecting normal system operations.

To further ensure reliable communications, the faulttolerant control processor performs error detection

and address verification tests in its Nodebus and

Fieldbus interfaces.

For enhanced reliability during maintenance

operations, the Control Processor 40 is equipped with

a recessed reset button, located at the front of the

module. This feature provides for manually forcing a

module power off and on (reboot) without removing

the module from the enclosure.

Diagnostics

The Control Processor 40 uses three types of

diagnostic tests to detect and/or isolate faults:

• Power-up self-checks

• Run-time and watchdog timer checks

• Off-line diagnostics

Power-up self-checks are self-initiated when power is

applied to the control processor. These checks

perform sequential tests on the various control

processor functional elements. Red and green

indicators at the front of the control processor module

reflect the successful (or non-successful) completion

of the various phases of the control processor startup

sequence.

The run-time and watchdog timer checks provide

continuous monitoring of control processor functions

during normal system operations. The operator is

informed of a malfunction by means of printed or

displayed system messages.

Off-line diagnostics are temporarily loaded into the

system for the purpose of performing comprehensive

tests and checks on various system stations and

devices. Using the off-line diagnostics, a suspected

fault in the control processor can be isolated and/or

confirmed.

Fieldbus Modules

Fieldbus Modules provide connection of digital I/O,

analog I/O, and Intelligent Transmitters to control

processors. There are two types of Fieldbus Modules:

Main and Expansion. Some main modules can be

expanded using an expansion module.

A wide range of Fieldbus Modules is available to

perform the signal conversion necessary to interface

the control processor with field sensors and

actuators. For further information on the Fieldbus

Modules, refer to the Fieldbus Modules Product

Specification Sheet (PSS 21H-3B1 B3).

Fieldbus Flexibility

The Control Processor 40 is used in three different

Fieldbus configurations, which provide broad flexibility

in Fieldbus implementation:

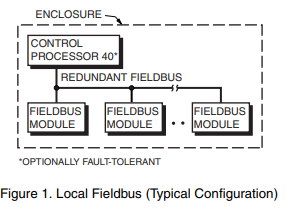

• Local Fieldbus (Figure 1) - Used only within the

enclosure, the local bus can extend up to 10 m

(30 ft). Up to 24 Fieldbus Modules (excluding

expansion modules) attach directly to the local

bus, which is redundant

• Twinaxial (Dual-Conductor Coaxial) Fieldbus

Extension (Figure 2) - Using twinaxial cable, the

Fieldbus can optionally extend outside of the

enclosure and can be up to 1800 m (6000 ft) in

length. Up to 64 Fieldbus Modules (excluding

expansion modules) attach to the extended bus

through Fieldbus isolators. (Up to 24 Fieldbus

Modules, excluding expansion modules, can

.png)

.png)

.png)