schneiderI/A Series® Hardware Control Processor 40

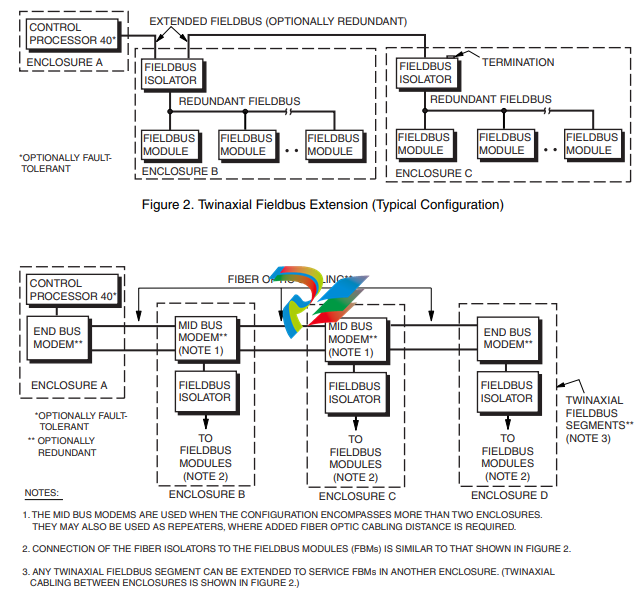

connect to each isolator.) The twinaxial Fieldbus

extension may be redundant.

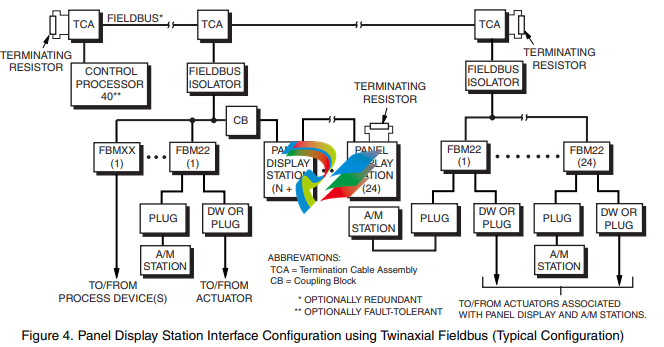

• Fiber Optic Fieldbus Extension (Figure 3) - The

fiber optic Fieldbus can optionally extend the

distance as well as add application versatility and

security. Overall Fieldbus length can be up to

20 km (12.4 mi). Like the twinaxial Fieldbus

configuration, the fiber optic Fieldbus

configuration supports up to 64 Fieldbus Modules

(excluding expansion modules), up to 24

Modules per isolator.

All three Fieldbus configurations use serial data

communication complying with Electronic Industrial

Association (EIA) Standard RS-485. The data

transmission rate is 268.75 Kbps.

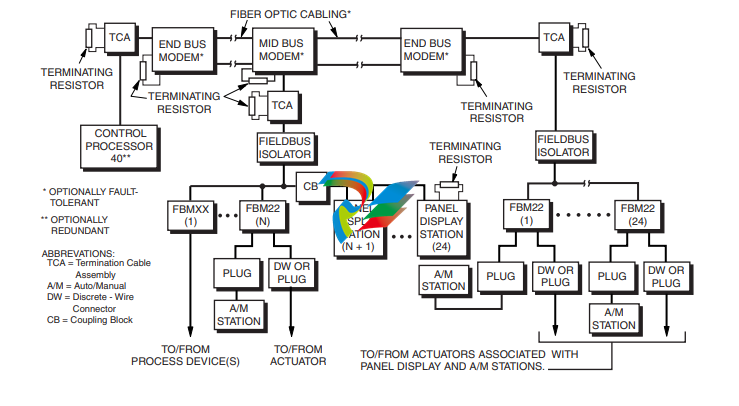

Panel Display Station Interfacing

The Control Processor 40 achieves the capability to

interface Panel Display Stations when the DSI (Panel

Display Station Interface) block is selected via the

configurator. In this capacity, the Control

Processor 40 can interface up to 24 Panel Display

Stations, or a combination of Fieldbus modules

(which may include associated Auto/Manual Stations)

and Panel Display Stations mixed on the same

Fieldbus. (Note, however, that per configuration rules,

one Panel Display Station counts as two Fieldbus

Modules.)

Control strategies should be planned such that all

blocks involved with the Panel Display Station,

Auto/Manual Station, and the control loops being

monitored or controlled are in the same Control

Processor 40, and ideally in the same compound.

The Control Processor 40 connects to the Panel

Display Stations and Fieldbus Modules via either of

two types of Fieldbus communications media:

twinaxial cable or fiber optic cable. Figure 4 shows a

typical twinaxial Fieldbus configuration, and Figure 5

shows a typical fiber optic Fieldbus configuration.

(Refer to Fiber Optic Fieldbus Product Specification

Sheet PSS 21H-7P1 B3 for additional fiber optic

Fieldbus application information.)

Cluster I/O Subsystem Interfacing

The Control Processor 40 interfaces with the Fieldbus

Cluster Input/Output Subsystem that consists of the

Fieldbus, a multi-slot chassis configuration of a

Fieldbus Processor (FBP10), analog/digital Fieldbus

Cards (FBCs), and power supply and power monitor

card. These Cluster I/O subsystems meet the needs

of applications where a high number of channels per

card are required. Figure 6 shows a typical twinaxial

Fieldbus configuration. (Refer to the Fieldbus Cluster

I/O Subsystem PSS 21H-2T1 B3 for additional

information.)

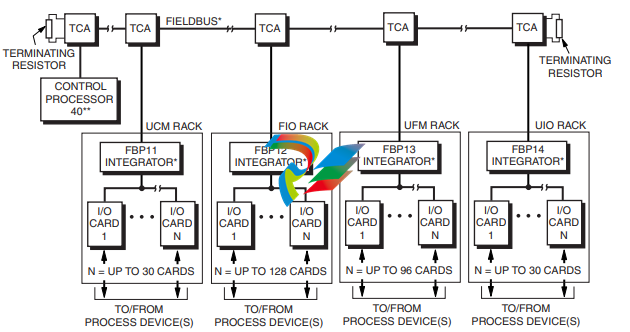

SPECTRUM Migration Interfacing

The Control Processor 40 interfaces with a

SPECTRUM Migration Integrator subsystem via a

single or redundant I/A Series Fieldbus and a

Fieldbus Processor (FBP) with built-in FBP isolator

located within the subsystem. There are four different

FBP integrators to accommodate Unit Control

Modules (UCM), Field Input/Output Units (FIO),

Universal Field Multiplexers (UFM), and Universal

Input/Output Units (UIO).

The CP40 control strategy can include any of

following SPECTRUM configurations:

• a single SPECTRUM Migration Integrator

subsystem

• multiple types of SPECTRUM Migration

Integrator subsystems

• Fieldbus Modules (FBMs) and/or other Fieldbusbased process interface subsystems along with

the SPECTRUM Integrator subsystem(s)

Control is via the software resident in the FBP

Integrator and in the SPECTRUM I/O Equipment

Control Blocks (ECBs) operating at the CP level.

Figure 7 illustrates a typical configuration with

multiple types of Integrator subsystems with nests of

I/O cards. (Refer to PSS 21H-7Q1 B3 SPECTRUM

Migration Integrators for additional information.)

Figure 7. Twinaxial Fieldbus SPECTRUM Migration Subsystem Interface Configuration (Typical Configuration)

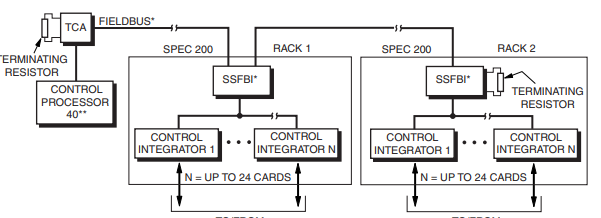

SPEC 200 Control Interfacing

For migration of SPEC 200 control to I/A Series

Systems, the Control Processor 40 interfaces via a

single or redundant I/A Series Fieldbus with the

SPEC 200 Control Integrator subsystem. This

subsystem consists of individual Control Integrators,

and Fieldbus Isolators attached within the SPEC 200

rack.

Control is via the software resident in the Control

Integrator and in the SPEC 200 I/O Equipment

Control Blocks (ECBs) operating at the CP level.

Figure 8 illustrates a typical configuration with

multiple Control Integrators in the SPEC 200

subsystem. (Refer to PSS 21H-7R1 B3 SPEC 200

Control Integrators for additional information.)

Figure 8. Twinaxial Fieldbus SPEC 200 Control Subsystem Interface Configuration (Typical Configuration)

SPEC 200 MICRO Control Interfacing

For migration of SPEC 200 MICRO control to

I/A Series systems, the Control Processor 40

interfaces via a single or redundant I/A Series

Fieldbus with the SPEC 200 MICRO Control

Integrator subsystem. This subsystem consists of

individual Control Integrators, and Fieldbus Isolators

attached within the SPEC 200 MICRO rack (NCM or

.png)

.png)

.png)