schneiderI/A Series® Hardware Control Processor 40

SPEC 200 2ANU).

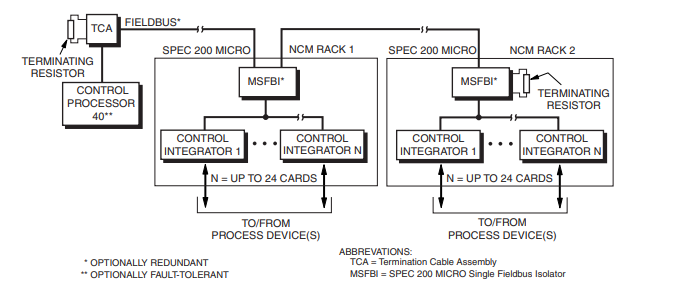

Control is via the software resident in the Control

Integrator and in the SPEC 200 MICRO I/O

Equipment Control Blocks (ECBs) operating at the

CP level. Figure 9 illustrates a typical configuration

with multiple Control Integrators in the SPEC 200

MICRO subsystem. (Refer to PSS 21H-7R2 B3 SPEC

200 MICRO Control Integrators for additional

information.)

Control Processor 40 Upgrade

Upgrading a Control Processor 30, Control Processor

10, Tank Processor 10, or Display Processor 10 to a

CP40 involves:

• Replacing the existing Control Processor with a

CP40

• Upgrading the software license

• Modifying the System Configurator to identify the

CP40

• Loading existing compounds to the CP40

Twinaxial Fieldbus SPEC 200 MICRO Control Subsystem Interface Configuration (Typical Configuration)

Processor Type

CONTROL PROCESSOR

Microprocessor-based Intel 486DX4 (running at

100 MHz) with stored programs, using high-speed

communication capability.

NODEBUS PROCESSOR

82596CA LAN CoProcessor

FIELDBUS PROCESSOR

8344AH MicroController with serial port

Memory

SIZE

4 MB storage

ERROR DETECTION

Parity provides single-bit error detection for each

byte.

Process I/O Communications

LOCAL TWINAXIAL(A) FIELDBUS

Type

EIA RS-485

Distance

10 m (30 ft)

Transmission Rate

268.75 Kbps

EXTENDED TWINAXIAL(A) FIELDBUS(B)

Type

EIA RS-485

Distance

1800 m (6000 ft)

Transmission Rate

268.75 Kbps

FIBER OPTIC FIELDBUS(C)

Type

Optical

Distance

20 km (12.4 mi)

Transmission Rate

268.75 Kbps

Process I/O Capacity

LOCAL

24 Fieldbus Modules(D), maximum

EXTENDED

64 Fieldbus Modules(D), maximum (24 maximum on

any one Fieldbus isolator)

PANEL DISPLAY STATION INTERFACING

Up to 64 FBMs(D) or FBM equivalents (24 maximum

on any one Fieldbus isolator). One Panel Display

Station counts as two FBMs. For example, if 24

FBMs are used, only 20 Panel Display Stations may

be used.

Power Requirements

INPUT VOLTAGE (REDUNDANT VOLTAGE)

39 V dc typical

CONSUMPTION (PER NON-FAULT-TOLERANT

MODULE)

15 W, maximum

Indicators

Red and green light-emitting diodes (LEDs) indicate

operational status.

Internal Diagnostics

Self-checking performed at power-up. Runtime checks

and watchdog timer function performed during

operation.

ENVIRONMENTAL SPECIFICATIONS(A)

Operating

TEMPERATURE

0 to 60°C (32 to 140°F)

RELATIVE HUMIDITY

5 to 95% (Noncondensing)

ALTITUDE

-300 to +3,000 m (-1,000 to +10,000 ft)

Environmental Contamination Level

Class G3 (Harsh) as defined in ISA Standard S71.04

Storage

TEMPERATURE

-40 to +70°C (-40 to +158°F)

RELATIVE HUMIDITY

5 to 95% (Noncondensing)

ALTITUDE

-300 to +12,000 m (-1,000 to +40,000 ft)

PSS 21H-1B3 B3

Page 11

(A) The environmental ranges can be extended by the type of enclosure containing the module. {Refer to the applicable Product

Specification Sheet (PSS) which describes the specific enclosure that is to be used.}

PHYSICAL SPECIFICATIONS

Configuration

Single-width processor module. The fault- tolerant

version consists of two single-width processor

modules with two interconnecting buses (X-bus and

Z-bus).

Mass (Maximum)

1.7 kg (3.75 lb) for a single, non-fault-tolerant module.

Mounting

May be placed in any of the following mounting

structure slots:

– 1 X 8 Mounting Structure

– Industrial Enclosures (IE16 and IE32),

Structural Foam or Metal

– Field Enclosure 8, Structural Foam or Metal

In the fault-tolerant version, the two modules must be

mounted in adjacent mounting structure slots with the

two interconnecting buses.

.png)

.png)

.png)